AKTOptimize

AKTOptimize will highlight live technology insertion and maintenance process learning applications that grab interest and enable participants to personally experience impact of this innovative training approach.

FRC challenges and shortfalls frequently result from deficiencies in human performance caused by lack of understanding new technology equipment/processes and complex or infrequently performed maintenance procedures. We enable artisans, Sailors and Marines to instantly understand new technologies and optimally perform new, complex and/or infrequently performed procedures through accelerated knowledge transfer.

Accelerated Knowledge Transfer (AKT) optimizes user learning and enables peak performance of all production and maintenance tasks in the FRCs. AKTOptimize demonstrations/discussions will cover overall AKT approach and include development details, along with specific Job Performance Aid (JPA), Learning Performance Aid (LPA), Augmented and Virtual Reality (AR/VR) examples successfully deployed across the DoD.

Focus Area: Workforce Development/Visualization

Contact

Michael Leigh

michael.leigh@aktoptimize.us

678-361-4322

Accelerated Knowledge Transfer Optimizing Productivity

Problem Statement:

Key FRC problem areas and challenges include:

- New technologies and capabilities such as fiber optic repairs and additive manufacturing

- Productivity issues

- Slow or inconsistent processing / high cycle times

- Achieving industrial / shop floor Quality Assurance

- Overall cost, readiness and/or safety concerns

- Effectively communicating lessons learned

Benefits Statement:

- Rapid learning optimizes technical understanding and maintenance productivity

- Enables consistent human performance with speed and accuracy of best-of-best maintenance subject matter experts (SMEs)

- Ensures correct first-time production/maintenance procedure completion and delivery

- Significantly improves production/maintenance quality and long-term effectiveness/reliability

- Reduces overall production/maintenance and material costs, while improving readiness and safety

Technology Solution Statement:

Innovative Maintenance Training Solution:

- Accelerated Knowledge Transfer (AKT) augments tech data, enabling visual/digital learning for fastest learners and users

- Modular approach / instant navigation provides self-paced capability that doesn’t leave slower or first timers behind

- Interactive & easily accommodates all four (4) learning preferences of reading, hearing, seeing and doing to overcome all challenges / problem prone areas and impart critical techniques

- Delivers just-in-time understanding at point of use/need

- Hardware agnostic and displays anywhere from all devices

- Rapid/easy updating ensures configuration management

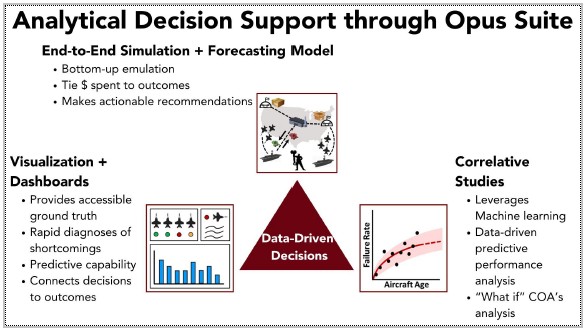

Andromeda Systems Incorporated

Andromeda Systems Incorporated provides tools and services to assist Physical Asset Owners, Fleet Managers, and Military Program Managers in gaining critical insights into their equipment’s performance, identifying system improvements, optimizing operations & support, making better business decisions, and achieving measurable life-cycle cost savings.

As a leading provider of professional and high technology services and solutions, ASI serves the Department of Defense, U.S. civilian agencies and private industry. ASI is a NSAI ISO 9001:2015 Certified company.

Focus Area: Workforce Development/Visualization

Contact

Dennis West

dennis.west@androsysinc.com

Maintenance Optimization

Problem Statement:

COMFRC is responsible for the arduous task of managing a complex network of Depots, I-level locations, and field sites to provide maintenance, repairs, overhauls, and parts manufacturing for the NAE. An integrated approach is necessary to optimize business practices and resource allocations in order to maximize weapons systems availability to the Warfighter.

Technology Solution Statement:

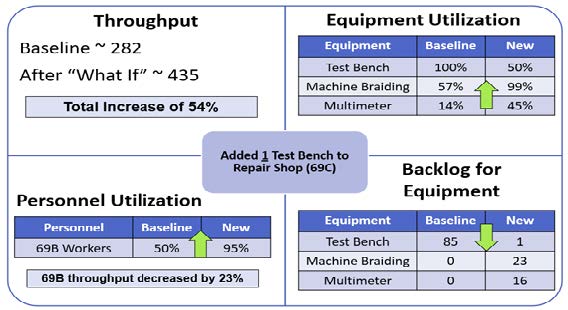

An enterprise wide modeling and simulation application is being developed that takes advantage of:

- Advanced computing capabilities

- Operations Research (OR) techniques

- Near Real-time data collection and processing of current NAE data systems

The application will serve as a Decision Support System to be used both at the enterprise level, as well as the local sites to improve and optimize operations

Benefits Statement:

- Application provides one integrated solution that considers impact of decisions made at a particular site to the other sites, and the enterprise as a whole

- Ability to run various scenarios to evaluate potential impact of any decisions or improvement initiatives

- Optimization algorithms allow for intelligent resource allocations, routing of workload, personnel scheduling

- Simple user interface allows stakeholders to make near real-time decisions to support enterprise operations in a dynamic environment

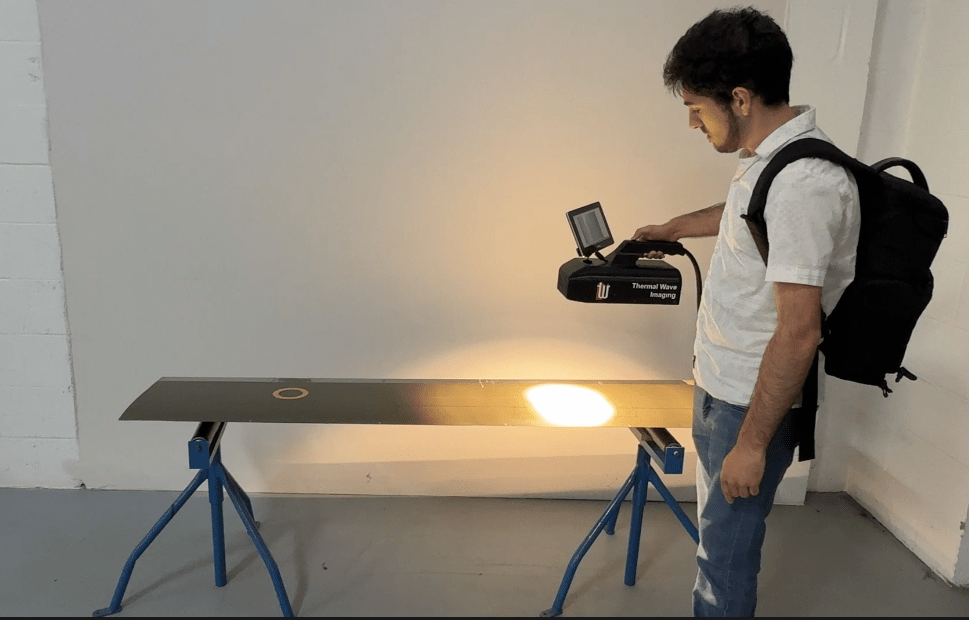

aRoboticsCo

aRoboticsCompany designs, manufactures, and operates robotic systems that perform work on the interiors and exteriors of large and/or significant assets and structures (skyscrapers, historical buildings, warehouses, bridges, tunnels, roadways, etc.). We specialize in making machines that optimize most required work for such structures, primarily: regulatory inspections, structural analysis, leak tracing, cleaning, and repair, Our services are utilized by a range of clients including engineering firms, property managers, and government agencies in need of a safer and faster alternative for rapid inspection. Our inspection technologies have received several industry awards/validations. aRc won the 2020 NYC Department of Buildings Innovation Challenge and the Propel by MPIM 2022 Business Competition. We were among 30 companies chosen for the NATO Defence Innovation Accelerator for the Northern Atlantic (DIANA) cohort, out of 1,300 submissions across North America and Europe in 2024.

Real-Time Weld Inspection Tool (RTWIT)

Problem Statement:

- Shrinking pool of certified weld inspectors extends shipyard availabilities

- Visual inspections miss sub-surface or geometry defects until costly rework is required

- Paper-based QA slows turnover and burdens sailors with manual data entry

- Confined spaces aboard vessels limit tripod-mounted NDT tools and external lighting

Technology Solution Statement:

The Real-Time Weld Inspection Tool (RTWIT) (pronounced “Rit-Wit”) is a self-contained, goggle-mounted augmented-reality system that turns a maintainer’s line of sight into a precision scanner. A fused time-of-flight depth camera and UV-Vis spectrometer capture 3-D geometry and arc chemistry at 30 frames s-1; onboard processing flags defects and projects corrective prompts directly onto the visor.

The sealed IP-67 headset runs six hours on internal batteries, records geotagged inspections offline, and shrugs off electromagnetic interference common around shipyard power tools. Eye-tracking lets operators pick measurement points hands-free, automatically delivering ±2 mm gauge readings and crater-volume estimates, even in total darkness.

Benefits Statement:

- Cuts weld rework hours by up to 50 % in civilian shipyard and Army depot trials

- Slashes inspection cycle time from 20 min to <5 min per joint

- Reduces dependence on Level III NDT billets, freeing scarce expertise for critical tasks

- Creates tamper-proof digital records aligned with NAVSEA Condition-Based Maintenance Plus (CBM+) goals

Automated Precision, Inc.

Automated Precision Inc. (API), founded in 1987 by Kam Lau, Ph.D., in Rockville, Maryland, is a leader in laser-based dimensional metrology solutions. API serves industries like aerospace, defense, automotive, energy, and manufacturing, delivering advanced measurement and calibration tools. The company is renowned for inventing the laser tracker and holds original patents for this technology, which remains central to its product line.

API’s flagship products include the Radian Laser Tracker, XD Laser, iScanMagic and iScanLite 3D scanners, and Dynamic 9D LADAR, designed for precision tasks like part inspection, assembly, machine tool calibration, and reverse engineering. These tools enable high-accuracy 3D measurements, supporting clients such as Boeing, Lockheed Martin, and Ford. API’s Smart Factory Inspection System and robotic calibration solutions, like RoboCal, enhance automation and efficiency in production.

The API Services division, launched in 2008, offers contract metrology, onsite calibrations, and training, backed by experts with over 200 years of combined experience. API operates globally, with offices in China, Germany, and India, and its U.S.-manufactured products are ISO 9001:2015 certified. Despite its innovation, employee reviews highlight challenges, including high turnover and outdated product perceptions, with a 2.4/5 Glassdoor rating. API continues to invest in R&D, driving Industry 4.0 solutions for integrated metrology across diverse applications.Focus Area: Advanced/Additive Manufacturing

Contact

Adam Hicks

757-846-3631

adam.hicks@apimetrology.com

Metrology Solutions

Problem Statement:

In today's fast-paced manufacturing and industrial sectors, companies face significant challenges in achieving precise, efficient, and cost-effective dimensional metrology. Manual measurement processes and outdated tools often lead to inaccuracies, prolonged production times, and increased operational costs. These inefficiencies hinder the ability to meet stringent quality standards, adapt to complex geometries, and integrate seamlessly with automated production systems, resulting in reduced competitiveness and profitability.

Technology Solution Statement:

Automated Precision Inc. (API) provides state-of-the-art laser-based dimensional metrology solutions to revolutionize precision measurement in manufacturing. Our industry-leading technologies, including the Radian Laser Tracker, Dynamic 9D LADAR, and iScanMagic 3D scanners, deliver high-accuracy, non-contact measurement capabilities for complex applications in aerospace, automotive, energy, and beyond. Integrated with API’s Smart Factory Inspection System and RoboCal robotic calibration software, our solutions enable seamless automation, real-time data acquisition, and precise quality control. Supported by advanced software and AI-driven analytics, API’s tools optimize part inspection, assembly alignment, and machine tool calibration, ensuring unmatched efficiency and compliance with Industry 4.0 standards. With global service support and ISO 9001:2015-certified manufacturing, API empowers clients to achieve superior precision and operational excellence.

Benefits Statement:

Automated Precision Inc. (API) delivers cutting-edge laser-based metrology solutions, including the Radian Laser Tracker and Dynamic 9D LADAR, empowering industries like aerospace, automotive, and energy to achieve unparalleled accuracy and efficiency. Our advanced tools and services streamline part inspection, assembly, and calibration, reducing measurement time and costs while ensuring compliance with rigorous standards. With API’s Smart Factory Inspection System and robotic calibration solutions, clients enhance automation,

boost productivity, and gain a competitive edge through precise, data-driven manufacturing processes.

BlastOne International

Focus Area: Coating and Corrosion Prevention

Contact

Brianna Cook

brianna.cook@blastone.com

614-695-5723

Originally established nearly 50 years ago to provide technical consulting, BlastOne has grown to become a single source supplier of blasting equipment, abrasives and know-how to customers all over the world. BlastOne operates internationally from several offices across Australia, New Zealand, North America and Europe. We stand behind our brand claim of superior performance. It’s something we define as ‘Performance3’—the result of combining superior know-how with superior abrasives and superior equipment. In short, it delivers greater cost-efficiencies for our customers.

Blast & Coating Equipment

Problem Statement:

The blasting and finishing industry faces critical challenges, including manpower shortages, downtime from faulty equipment, environmental and dust concerns, and significant operator safety and health risks. Facilities are expected to deliver more productivity, cost efficiency, and safety, yet struggle with inconsistent performance and equipment reliability.

Technology Solution Statement:

BlastOne’s Velocity™ System is a game-changing advancement that integrates seamlessly into high-pressure production environments. It is engineered to alleviate short-term blast and coat bottlenecks by combining cutting-edge technologies like Intelliblast Blast Pot Controls, Snakebite Blasting Nozzles, and Vortex Airflow Movement. Together these components act as a force multiplier, delivering exponential gains in productivity, reliability, and environmental safety while addressing the industry's most pressing challenges.

Benefits Statement:

BlastOne’s integrated solutions, including the innovative Velocity™ System, provide significant benefits by streamlining the blast and paint portion of production. This targeted approach reduces manual labor and enhances throughput in these critical processes. Proactive maintenance via BlastShield™ packages ensures reliable performance and minimizes downtime. Additionally, our solutions improve environmental outcomes and operator safety while supporting facilities in achieving their productivity and cost-efficiency goals.

COAST Autonomous

COAST Autonomous is redefining the future of industrial and military transportation. With nearly three decades of innovation, COAST specializes in deploying Autonomous Road Machines (ARMs) engineered to meet stringent machine safety standards. Unlike competitors focused solely on general automotive autonomy, COAST delivers ruggedized, infrastructure-independent, and scalable automation designed for real-world industrial applications. Focused on automation, digitalization, and operational efficiency, COAST is leading the transformation of critical industries through high-performance autonomous solutions.

Focus Area: Reliability Improvement (Hardware)

Contact

Pierre Lefevre

plefevre@coastautonomous.com

626-818-9252![COAST-COMBINED[40][72] COAST logo](https://ncms.org/wp-content/uploads/2025/07/COAST-COMBINED4072-scaled.png)

Autonomous Road Machines

Problem Statement:

There is a need for autonomous machines on the airfield, to execute dangerous, dirty or dull task on airfield (FOD Sweeping, Perimeter Security and Grass Cutting) under the under COAST C2 Command & Control system.

Technology Solution Statement:

The program aims to integrate advanced Physical AI solutions into commercial and military airfield management. Through an FAA & DOD pilot, COAST will demonstrate a unified Command and Control (C2) System that safely operates multiple autonomous ground-based robots:

- COAST’s Autonomous Polaris ProXD – Conducts Foreign Object Debris (FOD) sweeping to ensure runway safety.

- PME’s FRP-L – Strengthens perimeter surveillance as an airfield security force multiplier.

- Renu Robotics’ Renubot – Performs autonomous grass-cutting for optimal airfield visibility and safety.

Benefits Statement:

The AAI Next project demonstrated safe and efficient autonomous execution of various tasks under COAST C2 System on an airfield during 8 weeks.

Compass Systems, Inc.

Founded in 1997, Compass Systems, Inc. is a small business defense contractor delivering advanced engineering, manufacturing, and R&D services to the Department of Defense and commercial sectors. Headquartered in Lexington Park, MD, with an AS9100-certified manufacturing facility in Johnstown, PA, Compass Systems specializes in unmanned systems, air vehicle engineering, contract manufacturing, and robotics integration. Our team supports both manned and unmanned platforms, providing comprehensive lifecycle services from concept through deployment.

Compass Systems’ core capabilities include advanced aerospace structures, subsystem integration, autonomous and unmanned technologies, and rapid prototyping for electromechanical defense systems. We provide field-tested and mission-ready solutions tailored to enhance operational readiness and reduce downtime.

Our client base includes major DoD agencies and Tier 1 defense contractors such as BAE Systems, Lockheed Martin, Leonardo DRS, Verge Aero, Hurley IR, and Ghost Robotics. Our agile team and innovative technologies—such as our Augmented Reality Companion (ARC) System—position us to meet evolving mission demands and operational challenges in dynamic environments.

Focus Area: Workforce Development/Visualization

Contact

Johnny Lange

Johnny.lange@compass-sys-inc.com

240-496-3305

Augmented Reality Companion (ARC) System

Problem Statement:

- Limited access to technical documentation in the field

- High downtime due to complex or unfamiliar maintenance procedures

- Inefficient workflows during time-sensitive missions

- Lack of real-time collaboration with remote experts

Benefits Statement:

- Field-tested reliability in real-world military environments

- Reduced maintenance time and equipment downtime

- Increased task accuracy and technician confidence

- Seamless integration with existing workflows and tools

- Scalable for future collaboration and data-sharing capabilities

Technology Solution Statement:

The ARC System delivers immediate access to equipment manuals, schematics, and technical guidance through an intuitive augmented reality interface, enabling users to complete complex tasks efficiently. Streamlining maintenance procedures with step-by-step visual overlays minimizes downtime and reduces the need for extensive training. Built-in compatibility with existing workflows ensures smooth integration, while planned upgrades, such as real-time remote support, will further enhance collaboration, decision-making, and operational effectiveness in challenging environments.

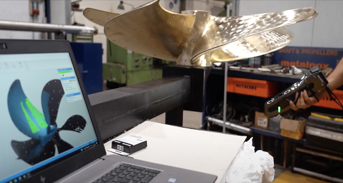

Creaform USA, Inc.

Creaform develops, manufactures and markets cutting edge portable 3D measurement and analysis technologies that increase productivity. Creaform offers innovative solutions for applications such as 3D scanning, reverse engineering, quality control, non-destructive testing, product development, and numerical simulation (FEA/CFD). Its products and services cater to a variety of industries, including automotive, aerospace, consumer products, heavy industries, healthcare, manufacturing, oil and gas, power generation, research and education.

With headquarters and manufacturing operations in Lévis, Québec, Creaform operates innovation centers in Lévis and Grenoble France, and has direct sales operations in Canada, USA, Mexico, Brazil, France, Germany, Italy, Spain, China, Japan, Korea, Thailand and Singapore. Creaform is a unit of AMETEK Ultra Precision Technologies, a division of AMETEK Inc., a leading global manufacturer of electronic instruments and electromechanical devices, with annual sales of approximately $4.0 billion. Customers benefit from fast, accurate, repeatable measurements.3D Scanning

Problem Statement:

There is a need for:

- Quick accurate and repeatable physical damage assessment and reporting of skins, body, structures, pressure vessels and fuel tanks

- Highly portable and easy to operate equipment for field technicians that supports design of replacement parts that can be locally sourced

Technology Solution Statement:

Creaform HandySCAN (mfg in Canada)

- HandySCAN BLACK+™|Elite and HandySCAN MAX™|Elite ISO 17025 certified accuracy.

- High Resolution

- Portable (only requires power & tethers to a laptop

Creaform VXsoftware

- Simplified interface for rapid & repeatable damage assessment replacing traditional pit gauge

- Monitor Damage over time, comparing one scan to future scans

- Extract measurements, features and cross-sections for reverse engineering with any professional CAD program.

- Supports Scan to Print

- Compare manufactured parts to nominal CAD or “golden” scan.

Benefits Statement:

- Scanning Simplicity

- Software and Hardware are mature in 4th & 5th Generations

- Hardware interfaces have been developed for any skill level to operate with minimal training.

- eLearning online training modules available for all software and hardware on demand.

- Software modules each have similar familiar interfaces making learning easier.

- Highly Portable

- Each scanner is in a relatively small case and does not require a heavy tripod. Setup in 2-3 min.

- Certified Accuracy supporting mission readiness

DES

Defense Engineering Services, LLC (DES) provides design and build services, technical solutions, and custom tools/machines for a variety of industries. DES offers mechanical and electrical design solutions combined with the ability to prototype, test, and manufacture hardware. DES’ prototype capabilities include metal fabrication, CNC machining, welding, integration, and assembly. With specific experience in design for military applications, automotive, aviation, armor, mission kits, missile defense, submarine systems, and ship systems, DES works across multiple branches of the US Military and other commercial industries.

Focus Area: Advanced/Additive Manufacturing

Contact

Greg Gordon

greg.gordon@defengserv.com

843-469-0434

Bearing Liner Measurement Project

Problem Statement:

The integrity of spherical bearing liners used in the swashplate/pitch assembly of aircraft is critical to ensuring safe and reliable operation. However, current methods for evaluating bearing liner thickness and radial wear are limited in accuracy, efficiency, standardized tools and processes, and practicality, particularly for on-aircraft inspections. These limitations pose significant challenges to maintenance crews, increasing the risk of undetected wear, premature component failure, and reduced operational readiness.

Technology Solution Statement:

The Spherical Bearing Liner Integrity Evaluation Project delivered a specialized inspection and measurement tool designed to evaluate the integrity of spherical bearing liners used in the swashplate/pitch assembly of aircraft. The tool addresses the challenges of accurately measuring bearing liner thickness and radial wear, in a controlled consistent manner. The tool can be used to determine “good” and “bad” bearing liners, as well as gather critical information for evaluating lifecycle and maintenance planning.

Benefits Statement:

DES’s specialized inspection and measurement tool addresses critical challenges in maintaining the integrity of spherical bearing liners. The tool enhances the Navy’s ability to perform precise and efficient maintenance, reducing the risk of undetected wear and premature component failure. The tool’s off-aircraft design simplifies operational use for maintenance crews, enabling 360-degree measurements and improving accessibility compared to on-aircraft solutions. Additionally, the tool supports predictive maintenance efforts, as the data on bearing liner wear can be analyzed to forecast lifecycle trends and optimize maintenance schedules, resulting in improved aircraft reliability, reduced downtime, and enhanced mission readiness.

DIT-MCO International

For cable testing, harness testing and other automated product testing, customers rely on DIT-MCO wiring analyzers. DIT-MCO is your complete solution provider for electrical testing of cables, harnesses, wired boxes, panel assemblies and more. From simple cables to complex assemblies requiring EE & LM, DIT-MCO has the solution. We also provide custom adaptation and test programming, giving you a complete turnkey solution.

Focus Area: Advanced/Additive Manufacturing

Contact

Tom Woosley

twoosley@ditmco.com

913-530-0874

Wire Harness Testing

Problem Statement:

Electrical wiring harnesses are inherently complex and labor intensive to build. Errors in the process occur everywhere from the first wire run to the last pin placed. With more than 80% of harness building done manually, eye strain, labor fatigue and simple human errors can lead to mistakes in the finished harness.

Benefits Statement:

- First ended pinning drastically reduces cross wiring errors

- Increased throughput

- Saves time and money

- Reduces labor fatigue and eye strain

- Portable testers to troubleshoot/repair wiring errors

- Final test solutions to guarantee 100% correct cables and harnesses

Technology Solution Statement:

DIT-MCO’s technology helps eliminate wiring errors. From the first connector being pinned, to the final point being tested, DIT-MCO offers products that provide solutions. PinMate, a guided wire insertion tool, helps operators insert wires correctly, ensuring less errors at final test. DIT-MCO’s analyzers aid in fault detection and troubleshooting of cables and wiring harness. This ensures mistake free harnesses, which is critical in the aerospace and defense world.

ES3

ES3 is a niche engineering firm providing specialized design, development, and fabrication of products for aerospace and other heavy industry sectors. ES3 has a purposeful business mission–to improve the performance, maintenance, and supply of mission-critical and safety-of-flight components while reducing the environmental impact of aerospace production processes and the hazardous exposures of aviation maintenance crews.

ES3 provides technical expertise in all aspects of landing gear systems research, test and evaluation, design and analysis, repair and maintenance. ES3 maintains a state-of-the-art facility along with engineering and testing staff to define component-specific parameters and procedures for applying advanced surface solutions as alternatives to coatings such as chrome or cadmium. Further, ES3 is a reliable source for developing highly-engineered electroplating, thermal spray, and plasma spray systems to meet the specific processing requirements of our customers.

Focus Area: Coating and Corrosion Prevention

Contact

Fred Laguines

fred.laguines@es3inc.com

478-298-8403

Dripless Repair System (DRS) for Zinc Nickel Brush Plating

Problem Statement:

DoD branches utilize low and high strength steel alloys on different weapon system components that require corrosion protection and cadmium has been the baseline coating for decades. The DOD typically brush plates steel parts from these weapon systems with Cd and outsources Cd tank plating to vendors. Cd is a toxic metal and known carcinogen that poses environmental, safety, and occupational health risks throughout the life cycle of the plated parts.

Technology Solution Statement:

The Dripless Repair System (DRS) for LHE alkaline Zn-Ni application is a system designed and manufactured by ES3. The system places a handheld plating applicator over the metallic surface intended to be coated. The DRS applicator forms a seal around the surface to prevent dripping of the solution from the aircraft component. The DRS can controllably apply Zn-Ni plating to metallic substrates

on aircraft without removing the components and without uncontrollable waste that requires chemical containment and hazardous waste disposal.

Benefits Statement:

Project has significant positive impacts to mission and readiness.

- Potential to result in elimination of brush cadmium across the USAF and DoD

- Reduction in hazardous waste disposal and ESOH compliance costs associated with the use of brush Cd and hexavalent chrome.

- Eliminates the legal liabilities associated with cadmium, worker safety and health, cradle to grave management of previously Cd-plated parts, international requirements, etc.

- Allows for environmentally friendly, on aircraft repair saving time/cost compared to immersion Zn-Ni

FLX Solutions

FLX Solutions develops advanced robotic systems that enhance mission readiness and safety by minimizing maintenance disruptions across defense operations — with expanding applications in industrial, transit, and construction sectors.

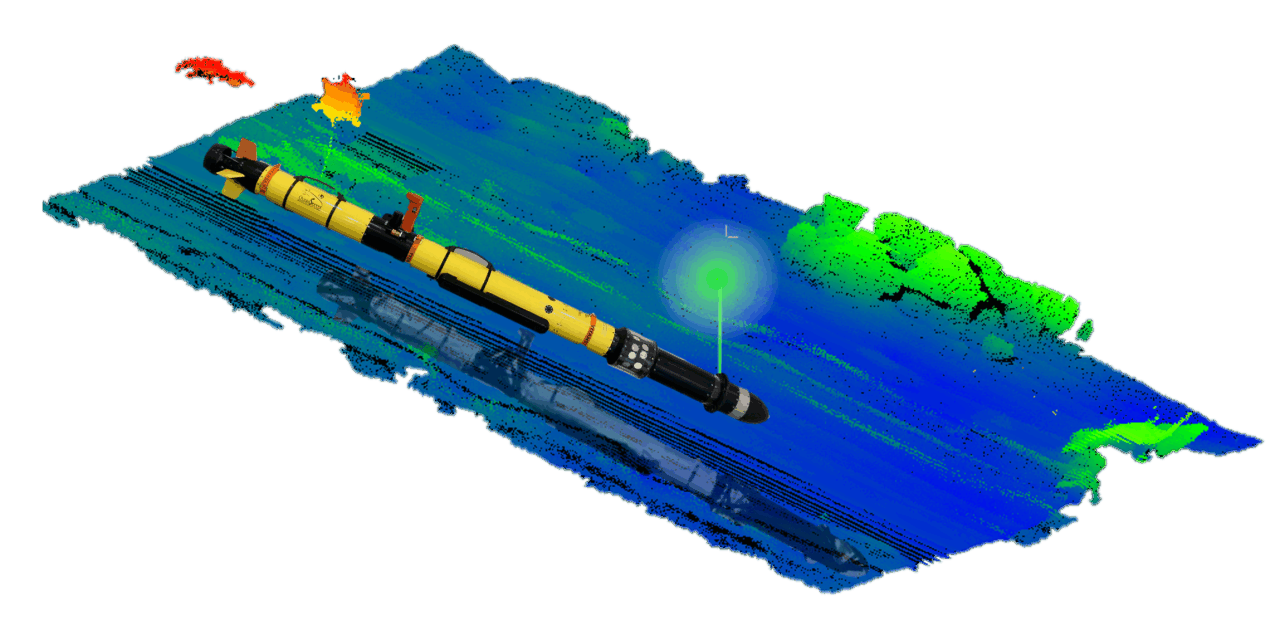

The FLX BOT is a compact, snake-like collaborative robot (cobot) that transforms inspection and maintenance for defense and industrial environments. Just 1″ in diameter, it navigates confined or hazardous spaces on ships, bases, and aircraft. Operated by a single technician via handheld control or extension pole, it reduces labor and improves safety. Its modular design includes interchangeable links with advanced cameras and sensors for autonomous obstacle avoidance. Plug-and-play end effectors — such as 4K, 360°, and 3D cameras, NDT sensors, thermal imaging, grippers, leak detectors, and sprayers — enable rapid adaptation for diverse tasks.

The FLX BOT minimizes the need for dangerous teardown or scaffolding and enables quick, accurate inspections. Designed for grab-and-go deployment, it reduces downtime and supports preventative maintenance. Its patented design offers greater articulation, lighter weight, and a smaller footprint than competing robots — at a fraction of the cost. Field-ready and validated, FLX BOT has completed and launched pilots with the U.S. Navy (corrosion assessment, 3D tank mapping), U.S. Air Force (aircraft wing fuel tank inspections), and a major DOD Prime.

Focus Area: Enhanced Inspection

Contact

Erik Hummel

erik@flxsolutions.com

267-733-3981

FLX BOT: Intelligent Robot for Tight Space Inspections & Maintenance

Problem Statement:

Maintenance and DoD technicians face major challenges inspecting and sustaining critical equipment on aircraft, ships, and remote bases. Many areas are confined, hidden, or too dangerous to access safely. Tight turnaround times and unsafe conditions increase risk. Current methods rely on costly teardowns and hazardous scaffolding. There is a need for high-resolution inspection tools that access hard-to-reach spaces efficiently.

Technology Solution Statement:

The FLX BOT is a handheld, snake-like robot that navigates confined spaces in aircraft, ships, and bases with minimal training. Its slim, modular design uses interchangeable links with cameras and sensors for autonomous movement. Swappable end effectors—360°, 3D, thermal cameras, NDT tools, grippers, and more—enable diverse maintenance tasks. Lighter, smaller, and more flexible than robots costing 10x more, it fits in a briefcase. Programs are underway across defense, transit, and industry.

Benefits Statement:

FLX BOT improves inspection quality while reducing maintenance damage, injuries, and costs. Navy pilots showed 90% savings in time and expense for hard-to-reach areas. It decreases downtime through efficient preventative maintenance and faster recovery. Elevates spaces can be inspected from the ground, and the robot collects sensor data for predictive maintenance and documentation—even at the front lines.

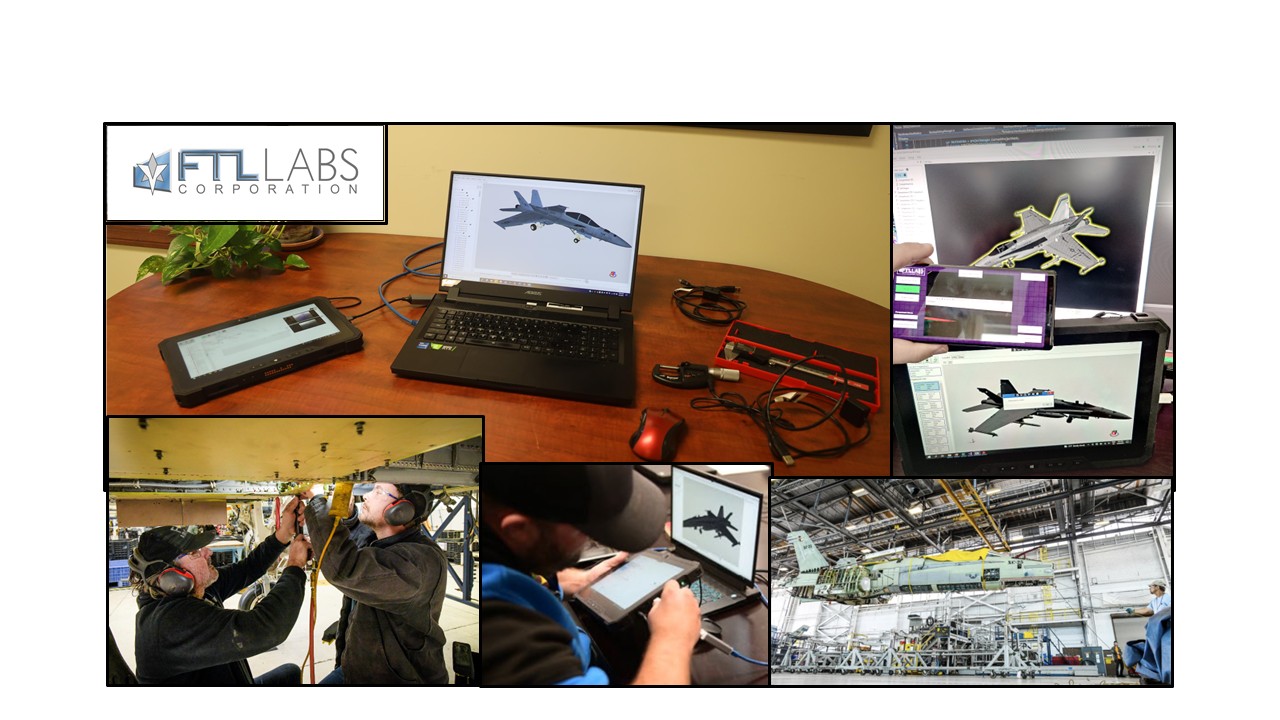

FTL Labs Corporation

FTL Labs Corporation is a small engineering research and development firm in Amherst, Massachusetts. FTL was founded based on a team-building culture that enables us to solve complex multi-disciplinary problems in advanced technology areas with contributions of experts across the globe.

The people at FTL Labs are committed to pushing forward the cutting edge of technology. Working with ingenuity, integrity, and professionalism, we solve our customers’ most challenging problems in aerospace, manufacturing, big data, medical, AI, and robotics sectors.

Some of FTL’s capabilities include:

- Rapid Prototype Design and Engineering

- Optics, Imaging, and Sensing

- Fuels and Fluids Analysis

- Human Performance Optimization

- Biotechnology

- Big Data and Artificial Intelligence

- VR/AR and Advanced Interfaces

- Custom Software Solutions

Focus Area: CBM+/Predictive Maintenance

Contact

Corey Countryman

corey.j.countryman.civ@us.navy.mil

360-315-7708

DADTMA (Distributed Acquisition Digital Twin Maintenance Architecture)

Problem Statement:

Traditional Maintenance, Repair, and Overhaul (MRO) practices in the DoD are struggling to adapt to increasing complexities in aircraft maintenance and quality assurance processes, including the use of digital tools and automated technologies to capture maintenance data and streamline workflow management. Current processes are inefficient, requiring time-intensive human-performed inspections and data collection before, during, and after maintenance tasks. The process frequently requires tedious and error-prone record keeping with pen and paper before transcription to a computer for access by teams.

Benefits Statement:

Reducing costs and shortening maintenance turn-around times at aircraft depots is a high priority for the Navy. Responding to this need, DADTMA reduces manpower-intensive engineering costs associated with repair and maintenance inspections by accelerating data collection on depot floors and enabling the transfer of that data, along with asset and maintenance process information to the DADTMAnet Digital Twin. Primes such as Northrop Grumman anticipate a 10% time-reduction in inspections, yielding $10M in savings in lifecycle cost for a single product.

Technology Solution Statement:

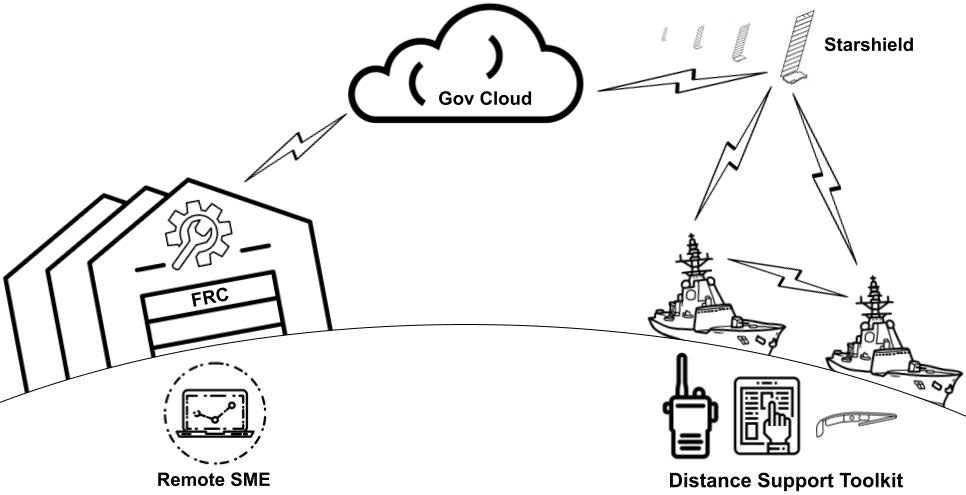

DADTMA is a software solution designed to collect, store, and analyze damage and repair data during naval depot maintenance and sustainment activities. DADTMA consists of a tablet app and a web app working in concert to rapidly collect data and store it in a Digital Twin in a secure GovCloud database. It employs automated USB tool data entry, 2D and 3D imaging, graphical database storage, data mining tools, and graphical data analysis to locate and track maintenance issues that are otherwise difficult to discern. It enables communication of that information across the Navy’s current software ecosystem. Ultimately DADTMA will provide a Naval Depot Maintenance and Sustainment tool that will increase the efficiency, repeatability, and accuracy of inspection results, for any asset type.

DADTMA integrates with USB tools used on depot shop floors and helps artisans organize that data by creating customized grids on 2D images of the work area. It then streamlines data sharing across sustainment roles by creating reports and integrating data to DADTMA’s web app. DADTMA’s website is accessible to anyone with the correct credentials, per our DoD customer’s defined roles. Finally, DADTMA’s Digital Twin provides predictive maintenance insights by comparing past maintenance events across a single or similar asset(s).- Rapid Prototype Design and Engineering

LMI

At LMI, we’re creating innovative solutions to transform emerging needs into extraordinary impacts at The New Speed of Possible™. Combining a legacy of federal expertise with an innovation ecosystem, we minimize time to value and accelerate mission success. With an emphasis on agile development and human-centered design, we enable agencies to experience solutions faster and conquer their toughest challenges sooner.

Focus Area: Business IT and Analytics

Contact

Scott McAllister

smcallister@lmi.org

252-635-8753

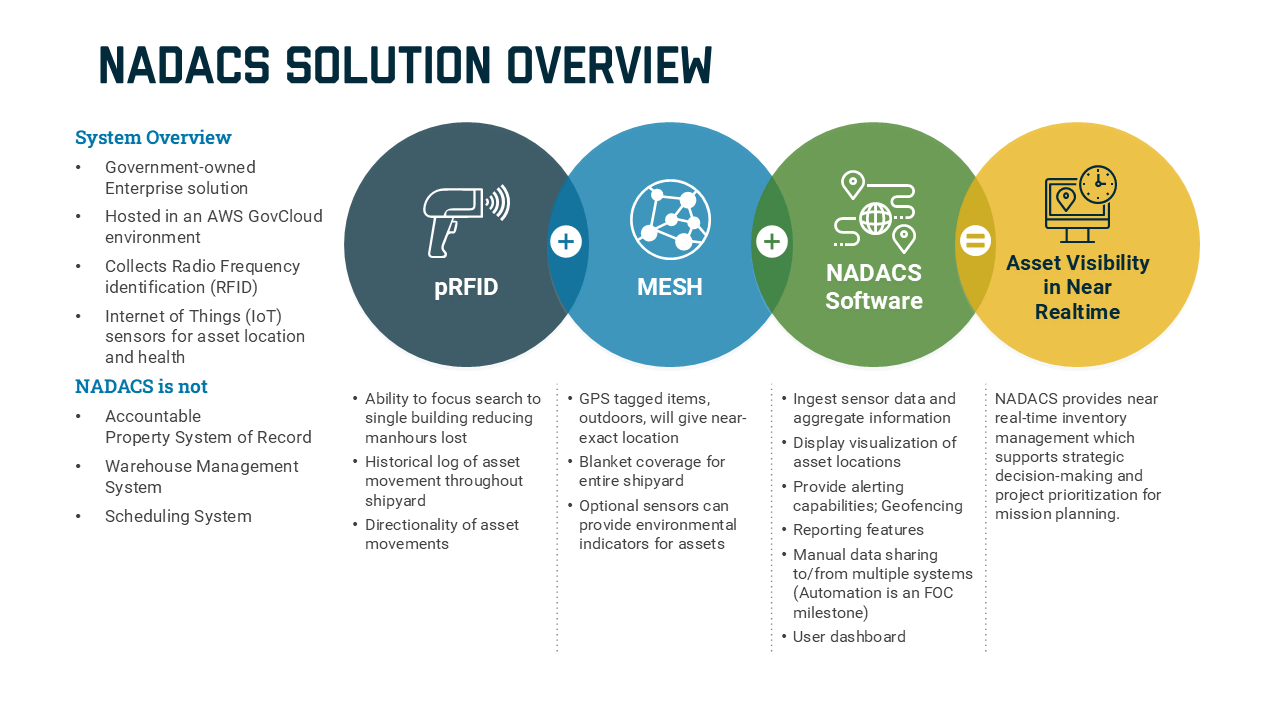

NADACS and LIGER for Mx

Problem Statement:

- Millions lost annually due to untracked or unlocatable inventory.

- Ship repairs delayed while searching/reordering parts.

- Fulfillment slowed by misplaced or moved inventory.

Technology Solution Statement:

The New Automated Data Acquisition and Control System (NADACS) is designed to revolutionize the efficiency, accuracy, and reliability of data management and control processes. By leveraging cutting-edge technology, NADACS seamlessly integrates advanced data collection methods with real-time processing capabilities to optimize operational performance across various industries.

Our NADACS solution ensures precise data monitoring, robust control mechanisms, and comprehensive analytics, empowering businesses to make informed decisions. With user-friendly interfaces and customizable features, NADACS provides unparalleled flexibility and scalability. In essence, NADACS transcends traditional data acquisition and control systems, offering a holistic approach that enhances productivity, minimizes risks, and drives sustained growth.

Benefits Statement:

NADACS transforms connected logistics by implementing a flexible, near real-time system that provides asset location and condition details using wireless sensor mesh and pRFID devices to collect data.

LoneStar NDE Innovations

At LoneStar NDE Innovations, we blend cutting-edge software and hardware to redefine the future of inspection technology. Our story is rooted in a commitment to simplify complexity—providing CAD-free inspection path planning that allows for seamless operations. With minimal setup and no required programming, efficiency is our hallmark. Our collaborative robotic (Cobot) inspections are designed to complement human expertise, ensuring that every endeavor is productive and intuitive. LoneStar NDE Innovations offers a variety of products from portable handheld units to scalable robotic systems. We also work on custom solutions. Our products are designed to support the inspection of components through their entire lifecycle, from development to in-service. We serve a variety of industries from aerospace (i.e., aircraft, rotorcraft, launch vehicles) to renewables (i.e., wind energy), and more.

Focus Area: Enhanced Inspection

Contact

Ben Blandford

bblandford@lsnde.com

972-400-2130

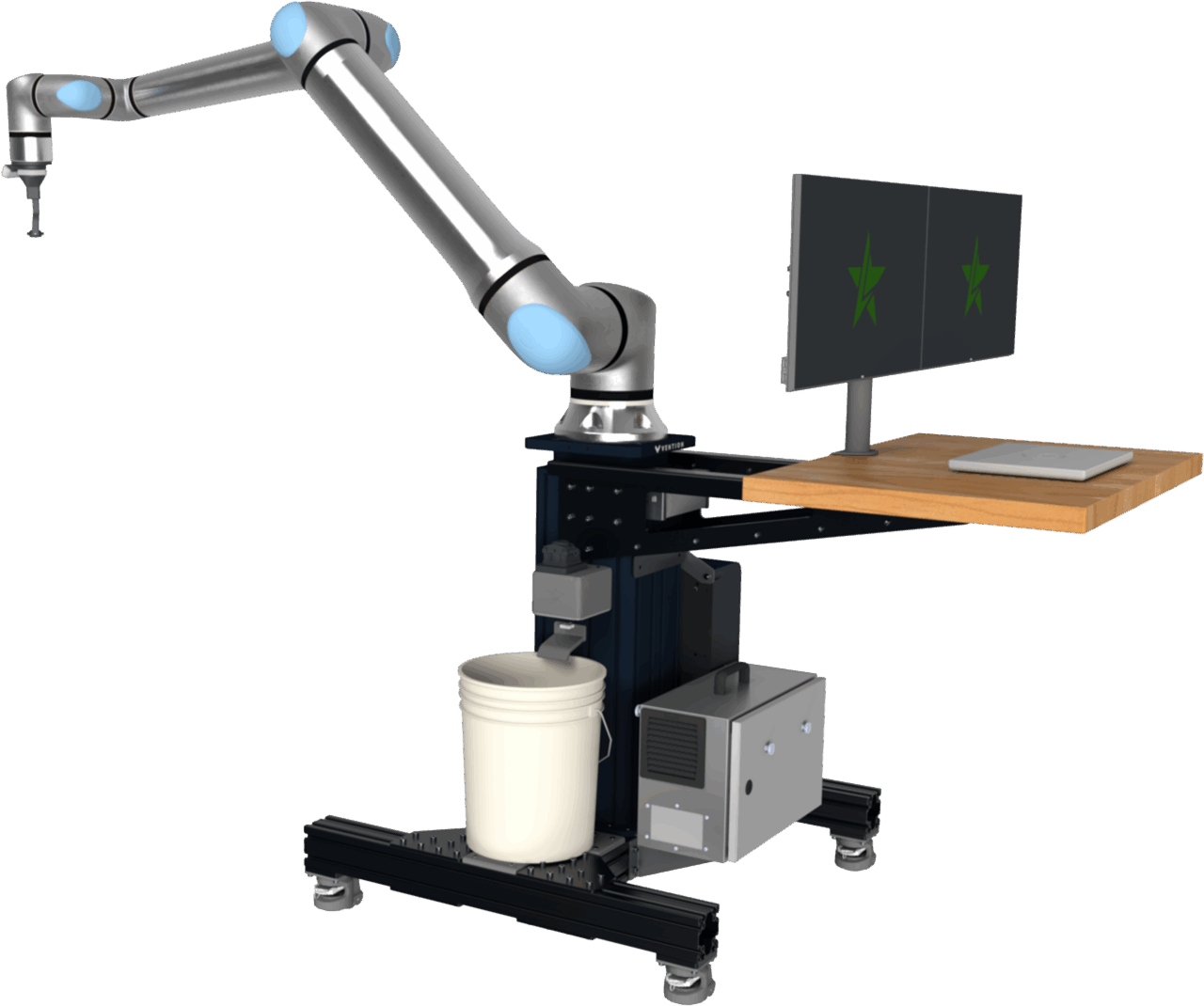

Inspection Cobot

Problem Statement:

- Difficult interpretation of traditional A-scan data. Wrong decisions can be made. Significant time required for A-scanning of structure.

- Time intensive engineering decisions based on A-scan inspection. Disposition of anomaly is a significant challenge.

- Technician fatigue during inspection.

- Lack of drawings/CAD for legacy platforms, make automating inspection very difficult.

Technology Solution Statement:

The LSDNE collaborative robot inspection tool (Orion) is rapidly deployable (< 10min set up), fast (up to 40 in/sec), and provides intuitive results (3D C-scans for rapid decision making). Using a 3D depth camera, novel path planning software, and novel sensor end effectors make the setup, process of inspecting. and disposition streamlined. Data is archived in open data HDF5 format that can be analyzed using the LSNDE or with custom algorithms that the user may already have.

Benefits Statement:

- Up to 40in/sec scan speed

- Less than 10min setup time

- No inspector fatigue, because the process is automated.

- Up to 5 times faster decision making

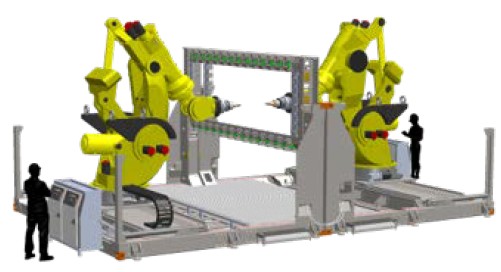

Machina Labs

Machina’s Robotic Craftsman is an agile manufacturing platform integrating 7-axis robots, autonomous sheet loading and fixturing, and advanced AI process models and closed-loop controls to enable many manufacturing processes at the click of a button. The robots have the ability to change tools and sensors instantly to perform a variety of operations such as roboforming, scanning, and trimming on a wide range of materials. The platform is continuously upgraded to improve existing capabilities and add entirely new ones.

Focus Area: Advanced/Additive Manufacturing

Contact

Matt Ragan

POC Email: matt.ragan@machinalabs.ai

POC Telephone: 757-971-1379

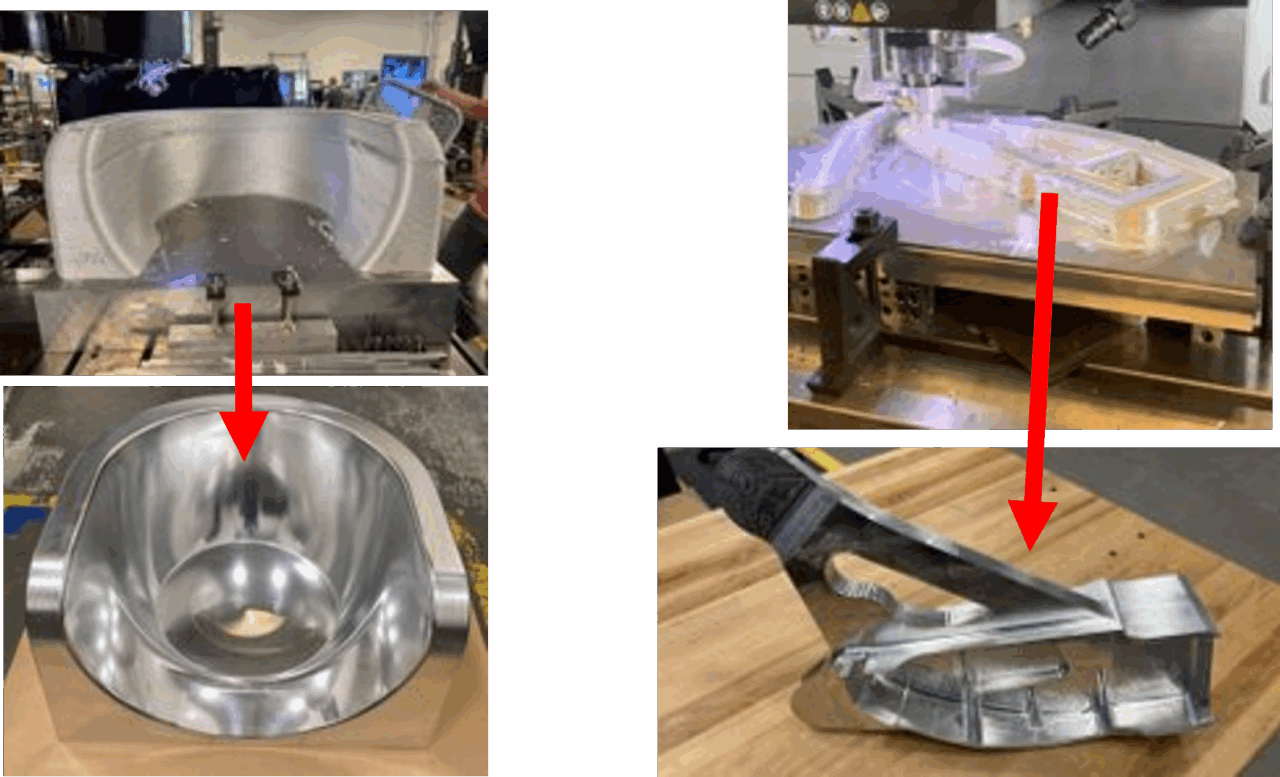

Robotic Incremental Sheetmetal Forming

Problem Statement:

The DOD continues to face overwhelming challenges in limited availability of mission ready defense systems. Missions are being compromised by antiquated manufacturing equipment, outdated supply chains and slow parts replacement times. These constraints impede the maintainer’s ability to address needed repairs quickly. A review by the U.S. Government Accountability Office (GAO) of 49 different defense aircrafts for 2011-2021 found that ONLY FOUR MET READINESS GOALS MOST YEARS and 26 did not meet their goals in any year.

Technology Solution Statement:

Robocraftsman Capability Description:

- Metal forming, trimming, hole cutting, drilling, and laser scanning (QC) capability (TRL 7)

- Containerized, two containers mate up to assemble the full system

- Rapidly-deployable via land, sea, air (C-5 or C-17)

- High availability and low maintenance

- Automated health-checks

- Digital traceability and reporting

Benefits Statement:

The introduction of the Machina Labs Robotic Craftsman into DoD aviation depos will modernize the organic manufacturing capability thus significantly reduce production time and cost enabling maintainers to get critical assets back on the flight line on time and on budget. This cutting-edge manufacturing platform integrates artificial intelligence (AI) and robotics to produce unique, affordable, and hard-to-source parts with unmatched speed. Per CMTA 2024 report by RSO (AFLCMC-2024-0128), a deployed RoboCraftsman can generate savings of over $85m during its projected 25-year lifetime resulting in real ROI in Year 2.

MDS Coating

MDS Coating is a world-leader in the application of erosion and corrosion resistant protective coatings for gas turbine engine compressor systems. Thousands of coated compressor sets have accrued millions of operational hours and have proven to significantly reduce operational and maintenance costs, reduce fuel consumption, improve flight safety and increase air vehicle readiness and availability.

As pioneers in PVD coating technology, MDS Coating continues to innovate to protect gas turbine engines in the military and commercial aviation sector.

Focus Area: Advanced/Additive Manufacturing

Contact

Marcio Duffles

marcio.duffles@mdscoating.com

202-409-1287

Erosion / corrosion protective coatings for gas turbine engine compressor systems

Problem Statement:

Erosion and corrosion of gas turbine engine compression systems.

Benefits Statement:

Retains engine performance leading to increased engine time on wing, lower maintenance and operational costs, reduced fuel consumption and improved flight safety.

Technology Solution Statement:

As pioneers in PVD coating technology, we continue to innovate ways to protect gas turbine engines. Our OEM-approved coatings protect airfoils against particle erosion, corrosion, and fluid erosion during engine operation.

MELD Manufacturing Corporation

MELD® is a solid-state large scale additive manufacturing and repair technology that does not melt the metal at any point in the printing process. Not melting the metal is the key difference between the MELD process and all other metal 3D printing processes.

There are 2 notable advantages to not melting the metal: 1) The metal is fully (100%) dense on the back end. 2) The metal can achieve forged properties.

These advantages enable MELD users to produce large scale near-net shape forgings at rapid rates and leverage them in their production processes to avoid long lead times regularly encountered when sourcing traditional forgings from overseas. This also allows manufacturers to shore up their domestic supply chain constraints. MELD Manufacturing Corporation (based in Christiansburg, Va) invented the MELD technology and manufactures machines that produce forged quality materials.

Focus Area: Advanced/Additive Manufacturing

Contact

Wes Downs

wes.downs@meldmanufacturing.com

619-433-9002

MELD – AFSD Printing

Problem Statement:

The government, OEMs, and Primes experience long lead times to source forgings from overseas. Forgings are used in critical applications and are essential to meet the needs of the warfighter. These long lead times create delays in the supply chain and impact downstream production timelines.

Technology Solution Statement:

The MELD technology is a new manufacturing process that enables the production of forgings at the point of need and eliminating long lead times. The cost savings and material savings can also assist in driving the business case for adoption. The MELD technology allows the government, OEMs and Primes to shore up gaps and pain points in the domestic supply chain.

During the MELD process, a solid bar filler material is forced to flow between the rotating MELD tool and the substrate,

whereby the filler material undergoes severe plastic deformation, dynamic recrystallization, and deposition. Due to its additive nature, MELD can be used for coating, repair, joining, or additive manufacturing applications of both similar and dissimilar materials.

Benefits Statement:

MELD does not require the utilization of laboratory-grade equipment, such as vacuum chambers, laser and e-beam systems, or powder beds. The MELD technology was developed to overcome the above-mentioned shortcomings of these more traditional melt-based metal AM and repair processes. MELD Manufacturing Corporation’s proprietary MELD technology (Additive Friction Stir Deposition – AFSD) is a solid-state, thermo-mechanical AM process that yields fully-dense products with wrought properties, reduced distortion, high deposition rates, and significantly faster throughput as post deposition material-processing (HIP, sintering, etc.) is not required. MELD is differentiated from other AM technologies because it is a highly scalable, open-atmosphere process with a high deposition rate that offers flexibility with material sets and yields a wrought microstructure on near-net-shape complex 3D structures.

The MELD technology solves dependency on foreign suppliers, and lead time and supply chain challenges facing maintenance, lifecycle, new construction, and repair for the Navy and the respective industries that support the Navy’s needs. Because of this, MELD machines have been purchased by the US Army, Navy, Air Force and DOE.

Merge Plot LLC

Merge Plot is a veteran-led technology company specializing in aerospace and defense. Established in 2024 as a Veteran-Owned Small Business (VOSB) based in the Greater Philadelphia area, our mission is to support the U.S. government, its allies, and commercial partners with advanced capabilities to address modern system challenges. Our team, shaped by decades of firsthand experience in the public and sectors, understands the critical need for reliability, precision, and adaptability in mission-critical environments. With active federal registration and membership in leading aerospace and defense technology consortiums, we are positioned to deliver cutting-edge solutions that address the evolving dual-use system challenges.

Focus Area: CBM+/Predictive Maintenance

Contact

Sean Danowski

sean@mergeplot.com

757-635-1251

QuickTurn Spatial Maintenance Platform

Problem Statement:

The Navy is currently unable to quantify the scope and cost of serious endemic issues such as corrosion across the fleet. Maintenance data is unstructured and stored in multiple siloed, text-based databases that are subject to input errors.

Technology Solution Statement:

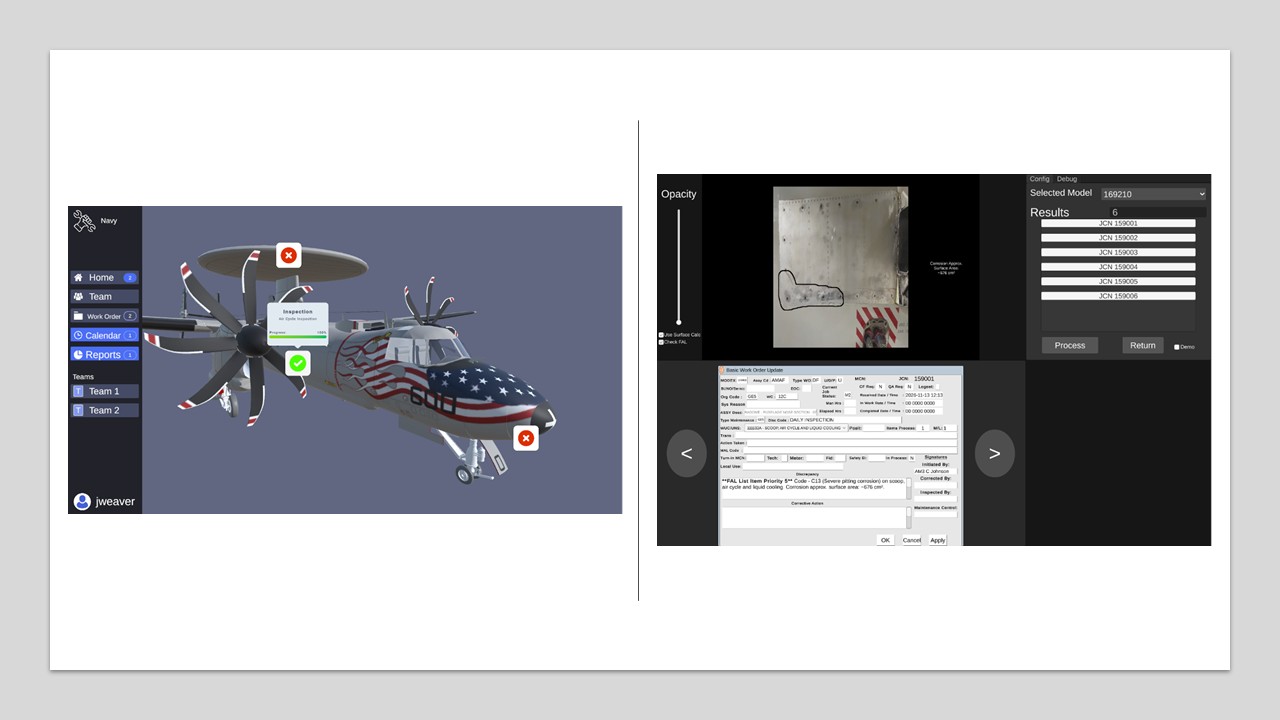

The QuickTurn digital twin environment is a new and improved maintenance ecosystem which transitions naval aviation maintenance from legacy, subjective, and paper-based workflows to a digital, objective, data-driven foundation, where aircraft maintenance data is highly structured and stored on a spatially-mapped three-dimensional digital twin of each aircraft.

Benefits Statement:

The QuickTurn spatial computing platform enhances naval aircraft maintenance within FRCs by creating digital twins of aircraft to improve efficiency, safety, and productivity. The platform will integrate mixed reality, AI, and ML to streamline maintenance workflows, connect directly with maintenance databases, and enable precise discrepancy reporting, such as corrosion quantification. By providing a robust framework for digital and physical model alignment, QuickTurn seeks to enhance naval aviation maintenance processes and support data-driven decision-making.

MxD

MxD advances economic prosperity and national security by strengthening U.S. manufacturing competitiveness through technology innovation, workforce development, and cybersecurity preparedness. An independent, nonprofit 501(c)3, public/private partnership with OSD-Research & Engineering’s Manufacturing Technology Program, we convene the industrial base to solve critical manufacturing challenges by accelerating digital adoption, empowering a skilled workforce, and modernizing supply chains. MxD is also the National Center for Cybersecurity in Manufacturing as designated by Congress and DoD. Located in Chicago, and driving innovation across the nation, MxD’s 22,000 sq. ft. factory floor is a dynamic showcase of advanced manufacturing technology use cases, shaping the future of American industry. We are on a mission to modernize the organic industrial base (OIB) including America’s public and private shipyards, airfields, arsenals, and depots using bleeding edge digital transformation techniques, processes, workforce development, and change management.

Focus Area: Advanced/Additive Manufacturing

Contact

Chris Dufour

chris.dufour@mxdusa.org

312-281-6887

MxD Sensor Kit

Problem Statement:

How to maximize machine uptime, and therefore minimize sustainment time, with a labor shortage, machine maintenance requirements, and unknown machine utilization. This challenge is resident at every FRC or Naval MRO facility with legacy equipment.

Benefits Statement:

- Digitalization method for OT machinery

- Low-code, easy-to-use

- Networked or air-gapped

- Data able to be integrated into dashboards and APIs

- 42 different use cases including pressure, hydraulics, weight, vibration, current, amperage, and more

- Simple RED-YELLOW-GREEN stacklight configurable to the use case

- Proven on the shop floors of several manufacturers and Portsmouth Naval Shipyard

- Low-cost, highly configurable

Technology Solution Statement:

The MxD Sensor Kit uses data driven, closed loop analytics to understand machine usage, prevent downtime, optimize maintenance, and better plan schedules. One kit, many use cases. Gain real-time equipment data to inform and improve operations and achieve Overall Equipment Effectiveness (OEE). Data collection and analysis helps enhance efficiency, productivity, and integration for future digital manufacturing modernization. Designed to be a simple, no-code solution that can be plugged in to any machinery, even legacy equipment. Provides a cost-effective solution to gather data and monitor various processes in an effort to reduce downtime and failures. Data-driven insights illuminate machine usage, minimize downtime, and improve scheduling to help reduce time spent on planned and unplanned work packages. Sensor Kits are made in America and infinitely scalable at affordable mass.

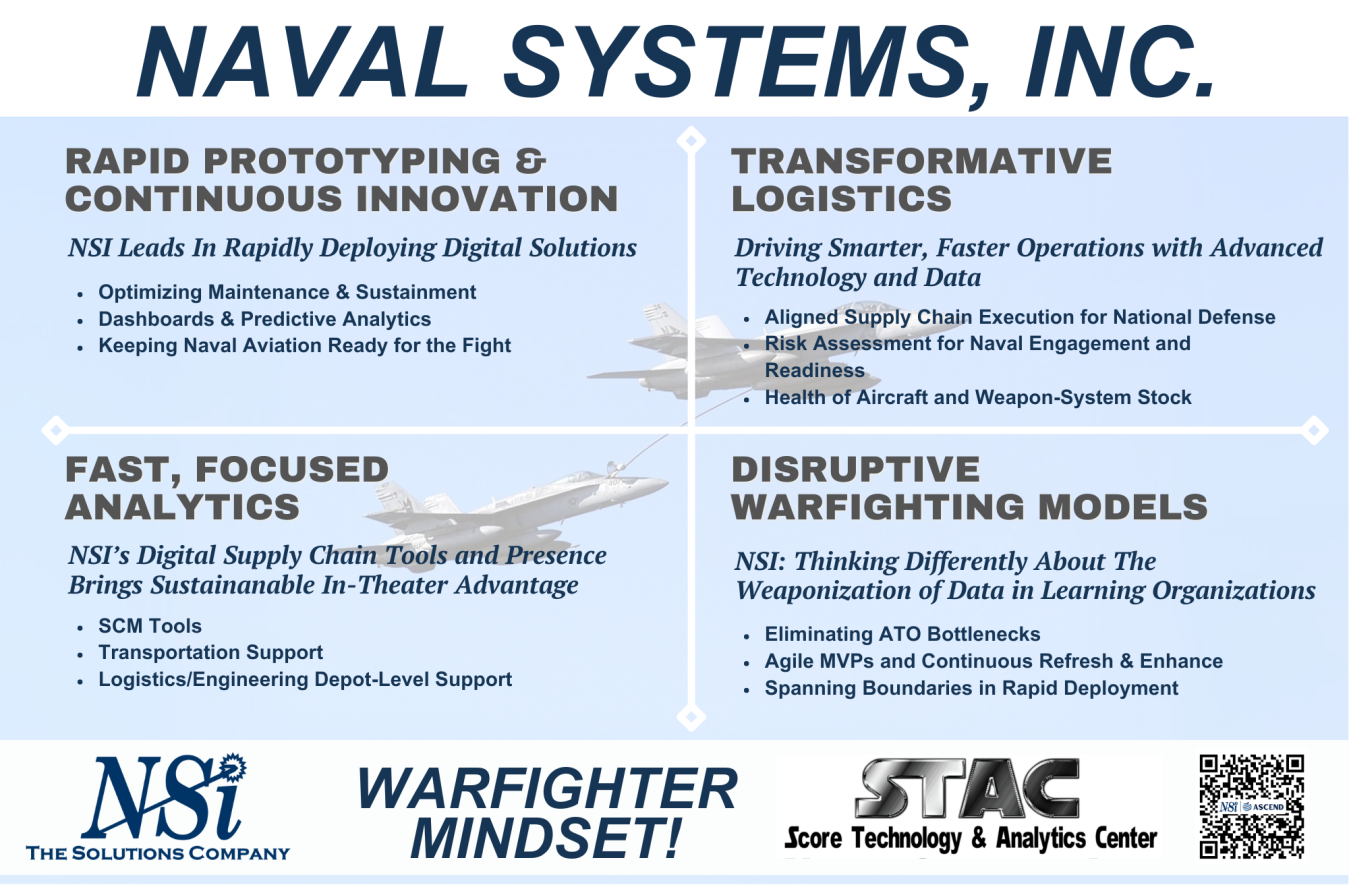

Naval Systems, Inc.

Naval Systems, Inc. (NSI) was founded in 2004 as an technical services company with the Navy’s Naval Air Systems Command (NAVAIR) as its primary customer. Since then, NSI has grown to over 300 employees and some 200 subcontractors, with its headquarters near NAS Patuxent River, MD, and personnel and satellite offices located across the U.S. and overseas. NSI supports USN, USMC, USAF, and US Army programs and associated Department of Defense (DoD) agencies responsible for delivering and sustaining advanced defense systems across warfighting domains.

NSI’s Score Technology and Analytics Center (STAC) empowers warfighters with superior analytics and business solutions. These efforts support the Naval Aviation Enterprise (NAE) with Big Data Analytics leveraging data from operational, maintenance and supply systems to provide key measures to decision makers.

NSI performs systems integration on multiple unmanned/autonomous systems out of its ISO 9001/AS9110 Panama City, Florida Product Integration Facility (PIF) and performs repair and rework as well as supply chain management activities out of its 60,000 SF ISO 9001/AS9120 facility in Jacksonville, Florida. These efforts are complemented by NSI’s core capabilities in logistics/integrated product support, maintenance planning and analysis, supply chain digital tool development, FMS case development and sustainment, and international airworthiness.

Focus Area: Business IT and Analytics

Contact

Ed Nork

enork@n-s-i.us

Application of Commercial Off-The-Shelf (COTS) FARO Quantum Laser ScanArm (FQLS)

Problem Statement:

- The current Navy-maintained Aerial Refueling Stores (ARS) are over 20 years old and many components are no longer manufactured.

- Corrosion on mission-critical assets often remains undetected until severe damage occurs.

- Traditional inspections lack continuous, actionable data, hindering maintenance prioritization.

- This gap increases unexpected downtime, repair costs, and reduces overall readiness.

- Defect detection is inconsistent, causing delayed repairs, increased costs, and reduced operational readiness across critical assets.

- Incomplete or inaccurate corrosion documentation limits root cause analysis and impedes long-term maintenance planning.

Technology Solution Statement:

- The FQLS enables rapid reverse engineering and reconfiguration of ARS pods by capturing components for redesign

- Supports full structural and material assessments to modernize a 20+ year-old system

- Identifies imperfections during MRO using 3D scanning, digital reproduction, and CAD

- Enhances durability, efficiency, and adaptability through precise analysis and redesign of ARS components

- Analytics- FQLS identifies hidden corrosion patterns and predicts high-risk areas, solving the challenge of unpredictable asset failures and enabling timely, targeted maintenance to prevent costly downtime.

Benefits Statement:

- An upgraded ARS and its components result in increased readiness, greater decision advantage, decreased risk, and cost optimization due to upfront resolution of structural and material issues.

- Quality control and safety go hand in hand as the ARS is revitalized and NSI provides solutions for engineering gaps and damaged or ineffective components.

- Increased reliability of the ARS, as well as upfront precise and comprehensive understanding of all actionable insights and solutions across varying levels of urgency.

Oerlikon

Oerlikon is a market leader in surface technologies. Our solutions encompass materials, coating equipment, coating services, and the engineering of entire plants. We build our business on unique technology competencies, a wide global reach and trusted customer relations in highly demanding industries, such as aerospace, automotive, energy, medical and luxury. Every day, we develop new materials, new surface technologies and new applications to empower our customers to create and innovate better products.

Focus Area: Advanced/Additive Manufacturing

Contact

Brian Crozier

brian.crozier@oerlikon.com

704-957-3873

Additive Manufacturing/Advanced Coatings

Problem Statement:

Lack of access to additive manufacturing and advanced coatings impacts supply chain management, component durability, operational costs, coating quality, performance and environmental safety.

Technology Solution Statement:

Oerlikon understands the properties of materials on the smallest scale and is a world-class materials manufacturer of metal- and ceramic-based powders and wires for coatings and other industrial applications. Oerlikon provides hundreds of diverse products, including thermal spray coating materials, auxiliary products and materials specifically for additive manufacturing.

Oerlikon offers one of the most comprehensive portfolios of surface technologies. Together with customers, Oerlikon develops customized solutions for multiple industries. We offer a standard portfolio and customized materials and surface solutions.

Benefits Statement:

- Additive Component Manufacturing (Laser-Bed, DED, MMC)

- Thermal Spray

- Thin Film Coatings & Equipment

- Advanced Materials for the Defense Industry

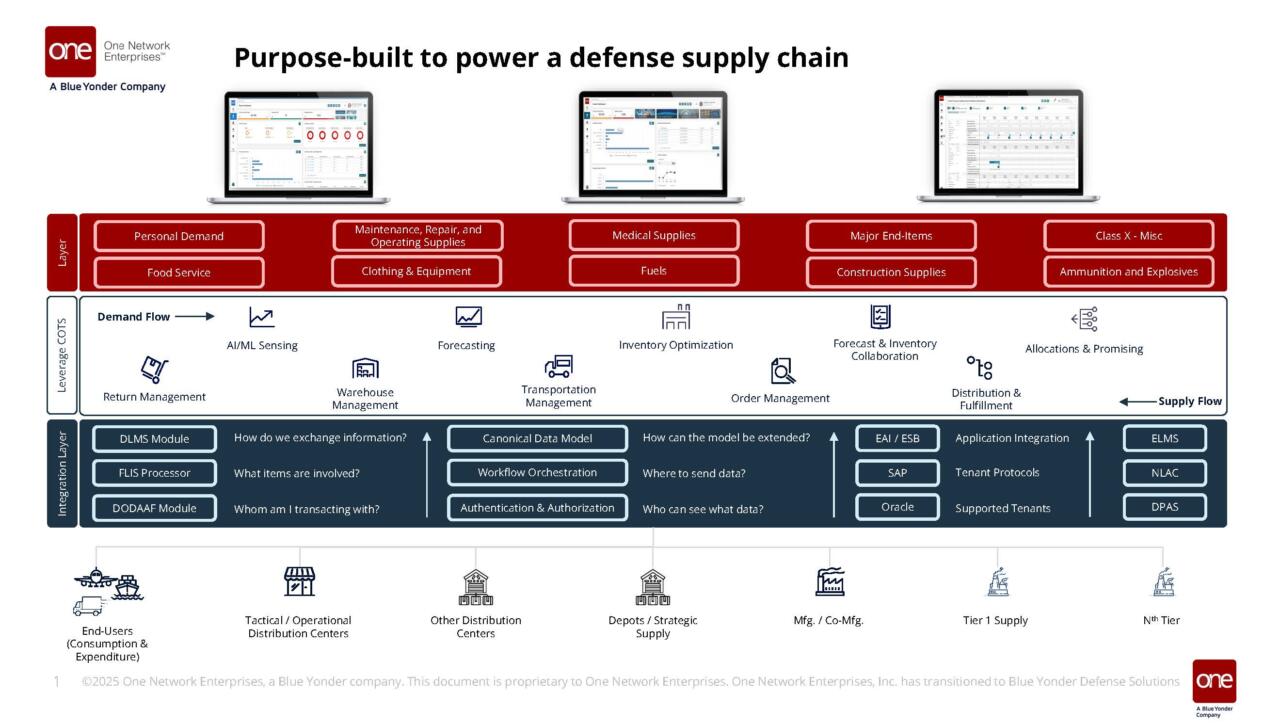

One Network Enterprises, A Blue Yonder Company

One Network Enterprises, a Blue Yonder Company, provides secure, AI-driven supply chain solutions designed to meet the complex demands of the defense sector. The company specializes in multi-enterprise, multi-tier integration, enabling seamless collaboration across the entire defense ecosystem — from government agencies and prime contractors to lower-tier suppliers and forward-operating units.

At the center of One Network’s offering is the NEO Platform, a cloud-based, real-time network that delivers end-to-end visibility, predictive analytics, and autonomous decision-making. This allows defense organizations to eliminate data silos, synchronize planning and execution, and improve readiness across all levels of supply.

One Network enhances its capabilities with Blue Yonder’s advanced planning and execution tools, offering a comprehensive digital solution that supports everything from tactical operations to strategic logistics. Its federated architecture ensures interoperability across systems and partners, which is essential for Joint All-Domain Command and Control (JADC2), contested logistics, and multinational coalition operations.

Proven in deployments with the U.S. Department of Defense and key defense agencies, One Network enables faster response to disruptions, greater supply resilience, and lower sustainment costs—ensuring mission-critical support when and where it’s needed most.NEO Platform—A Secure, AI-enabled, Multi-enterprise Network Designed Specifically for Defense Logistics

Problem Statement:

The US DOD global supply chain ecosystem faces increasing complexity in managing logistics across multiple tiers of suppliers, contractors, and coalition partners. Legacy systems and siloed data hinder visibility, slow response times, and prevent real-time coordination, resulting in higher costs, reduced operational readiness, and vulnerability to disruptions—especially in contested environments. The need for a secure, integrated, and intelligent logistics platform is critical.

Technology Solution Statement:

NEO Platform provides a secure, AI-enabled, multi-enterprise network designed specifically for defense logistics. By providing real-time visibility, predictive analytics, and autonomous decision-making across all tiers of the supply chain, One Network enables defense agencies and partners to collaborate seamlessly on a single operational platform. The solution enhances interoperability, reduces sustainment costs, and improves readiness by synchronizing supply planning and execution across the entire ecosystem—supporting agile, data-driven decision-making at both tactical and strategic levels.

• Digital Tracking for Improving Inventory Management, Supply Chain

• Artificial Intelligence & Machine Learning

• Fleet Data Analytics To Mitigate Degraders and Improve ReadinessBenefits Statement:

- End-to-End Visibility: Achieve a real-time view of assets, inventory, and shipments across all suppliers and partners.

- Increased Readiness: Rapidly adapt to disruptions and maintain mission-critical supply levels under any conditions.

- Reduced Costs: Eliminate inefficiencies and lower total lifecycle and sustainment costs through better coordination and automation and ONE’s Never Legacy commitment.

- Interoperability: Seamlessly connect with DoD systems, commercial providers, and coalition partners for unified operations. Audit enabled and ICAM capable.

- Scalable and Secure: A platform built for secure, multi-tier collaboration across both domestic and global defense environments.

Perfect Point EDM

Perfect Point EDM is an aerospace technology company specializing in innovative maintenance solutions that enhance safety, precision, and efficiency. Founded with the mission to transform outdated fastener removal methods, Perfect Point introduced the E-Drill—an electro-discharge machining (EDM) system designed specifically for the removal of “permanently” installed fasteners in aerospace structures. Traditional fastener removal methods rely on twist drills and manual cutters that are time-consuming, inconsistent, and prone to damaging aircraft components. Perfect Point’s E-Drill system replaces this process with a semi-automated plunge-cut EDM tool that delivers unmatched accuracy while eliminating debris, reducing ergonomic strain, and cutting removal time by up to 20x.

Perfect Point is committed to supporting aviation operators, OEMs, and MROs with tools that keep fleets mission-ready, reduce downtime, and protect high-value assets. Our solutions are designed with real-world maintenance needs in mind—streamlining workflows, improving consistency, and supporting technician safety across the aerospace industry.

E-Drill Fastener Removal Technology

Problem Statement:

The removal of “permanently” installed aircraft fasteners, by manual drilling, is often the most difficult, time-consuming, and dangerous aspect of depot-level aircraft maintenance. Damage from this process to both aircraft and artisans is common and a major cost driver.

Technology Solution Statement:

The E-Drill uses electrical energy to erode fastener head material without physical force, reducing the risk of damage to the airframe and technician. The system includes precision alignment tooling, a closed-loop water filtration system, and simplified controls—making it accessible to both experienced and new technicians. Implemented by both commercial and military MRO operations, the E-Drill has proven itself as a breakthrough solution for

complex, high-strength fastener types, including titanium and blind bolt fasteners.

- E-Drill is a semi-automated, plunge-cut Electrical Discharge Machining (EDM) tool that removes fastener heads using electrical energy

- Alignment tooling ensures fast cycle times, precise cuts, and minimal risk of damage

- Ergonomically designed for technician comfort and safety

- Operates with 110V power and standard shop air

- Recently authorized for official use by NAVAIR

Benefits Statement:

Studies have shown:

- 20x reduction in fastener removal time

- 75% reduction in maintenance-induced damage

- 30x reduction in consumable costs (no drill bits)

- Tooling can access ~95% of fasteners

- Elimination of FOD: no drill shavings

- Closed-loop system eliminates HAZ waste

- Significantly less heat introduced to the part

- Ergonomic process reduces technician strain

- Simplified operation shortens training time

PHM Technology US

PHM Technology is a leading provider of model-based engineering software that enables the commercial companies, Department of Defense (DoD), and defense contractors to design, analyze, and manage complex military weapon systems with greater safety, reliability, and mission readiness. Through its advanced Digital Risk Twin® technology, PHM Technology delivers a unified platform for assessing system performance, predicting failure modes, and identifying potential risks across the lifecycle of defense platforms. From aircraft and ground vehicles to naval systems and munitions, PHM Technology supports the DoD’s drive for innovation, accelerated certification, and enhanced operational resilience in modern military environments.

Focus Area: CBM+/Predictive Maintenance

Contact

Brett Petersen

brett.petersen@phmtechnology.com

866-214-9411

Digital Risk Twin

Problem Statement:

Accurately identifying, assessing, and mitigating design, safety, and reliability risks for modern defense and aerospace systems are difficult to achieve early in the product lifecycle. Traditional methods rely on fragmented tools, manual processes, and static models that limit the ability to perform comprehensive Failure Modes and Effects Analysis (FMEA), Functional Hazard Analysis (FHA), and Safety Case development in an integrated, traceable, and model-based environment.

Technology Solution Statement:

PHM Technology’s MADE (Maintenance Aware Design Environment) provides a model-based, integrated solution that enables engineers to systematically analyze, manage, and mitigate risks throughout the development lifecycle of complex defense and military systems. MADE transforms traditional, siloed engineering and safety processes by digitally connecting system design data with automated risk, reliability, and safety assessments.

Benefits Statement:

MADE (Maintenance Aware Design Environment) by PHM Technology provides a model-based, automated engineering environment that delivers significant operational and program benefits. MADE enables faster, more accurate risk identification and mitigation, reduces manual engineering effort, and enhances traceability across the system lifecycle. By integrating safety, reliability, and maintainability analysis into the early stages of design, MADE helps defense programs reduce certification timelines, lower life cycle costs, and increase mission readiness—all while improving confidence in system safety and performance.

The software allows users to generate Failure Modes and Effects Analysis (FMEA), Functional Hazard Analysis (FHA), Fault Tree Analysis (FTA), and Safety Cases directly from system models, ensuring consistency, traceability, and compliance with defense standards.

MADE integrates with existing engineering data sources and supports iterative design processes, enabling real-time risk assessment and continuous improvement. By providing a single, authoritative environment for safety, reliability, and maintainability analysis, MADE reduces manual effort, improves data integrity, and accelerates the path to certification and operational deployment for military weapon systems.

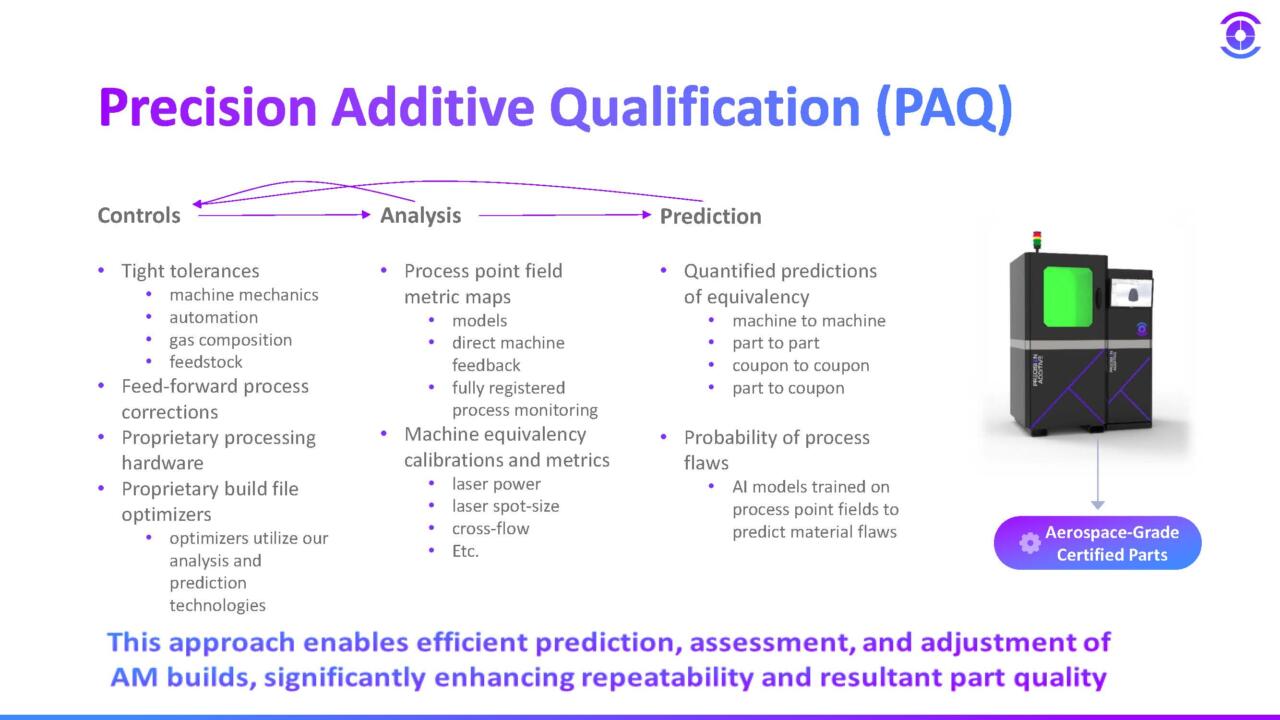

Precision Additive

Precision Additive Solutions, Inc. is advancing the Laser Powder Bed Fusion (LPBF) ecosystem with the first platform engineered specifically for the safe, repeatable, and high-quality production of aerospace-grade parts at scale. Our system is built to process reactive alloys (magnesium, aluminum, titanium), non-reactive alloys (Inconel, copper), and refractory metals (tungsten, molybdenum, cobalt) with precision, consistency, and industrial throughput.

We integrate three core innovations that set us apart:

Selective Stepped Laser Melting (SSLM™) – A proprietary process for adaptive melt control that enhances material integrity.

Specialized Architecture for Reactive Material Handling – Enabling safe and efficient processing of challenging alloys.

Precision Additive Qualification – A rigorous methodology that ensures repeatability and part certification for aerospace and defense.Our founder brings over two decades of experience in additive manufacturing, casting, and aerospace engineering. His patented technologies have supported national security and aerospace missions, including India’s Moon and Mars programs with ISRO.

Focus Area: Advanced/Additive Manufacturing

Contact

Mike Simek

mike.simek@precisionadditive.com

317-319-3953

3D+™ Hybrid Printing Technology

Problem Statement:

Aerospace and defense platforms depend on lightweight, high-performance materials, but the U.S. industrial base is no longer equipped to meet growing demand using traditional manufacturing methods. The supply chain for critical components has eroded due to domestic facility closures, reliance on foreign sources, and extended lead times. Meanwhile, additive manufacturing—particularly laser powder bed fusion (LPBF)—has not yet matured into a scalable, certifiable solution for standard aerospace metals such as aluminum and titanium.

Today’s production landscape faces four critical barriers:

- Diminishing Domestic Manufacturing Sources

- Raw Material Shortages and Extended Lead Times

- Material and Process Complexity

- Limited Scalability

Technology Solution Statement:

Our 3D+™ hybrid printing technology (currently in development) sets us apart. This integrates reactive and refractory material processing, in-situ quality monitoring, real-time adaptive print parameter adjustment capability, in-process machining, small, medium, and large-scale Laser Powder Bed Fusion (up to 1.2m x 1.2m x 1.2m build volume), and a new, high-speed, extremely low spatter laser printing technology in Selective Stepped Laser Melting (SSLM™). SSLM™ provides position-by-position melt pool control through dynamically adjusted colinear beam parameters. It enables spatial variation in energy delivery, adaptive focus diameter control, and real-time thermal regulation. These capabilities predict and minimize porosity, suppress spatter, and allow for both high-fidelity feature resolution and high-rate deposition. This results in exceptionally high-quality finished parts, and a digital twin of the entire build process.

To address throughput, stabilize production, improve safety, and minimize operator touch times throughout the part manufacturing life cycle, PA systems integrate the necessary post-processing steps as part of the printer and factory design, including automated de-powdering, stress relief, and heat treatment. Our machines are further optimized to match the needs of each material, allowing PA to specialize in printing reactive (e.g. magnesium, titanium, aluminum) and refractory (e.g. molybdenum, cobalt, tungsten) alloys.

Benefits Statement:

Precision Additive addresses enabling true viability for alloys already in use, and pioneering pathways for materials previously inaccessible to additive manufacturing. We have developed a holistic qualification strategy that reduces reliance on coupon testing and instead emphasizes robust process controls, in-situ monitoring, and quality assurance integrated into the machine design. In practice, this approach means strengthening QMS certifications, ensuring regulatory compliance, establishing material traceability, machine-specific baselining, statistical process control, qualifying final part performance, and fortifying data management and cybersecurity.

By shifting from labor-intensive coupon testing with limited process knowledge to advanced process monitoring and strict process discipline for informed testing, we can accelerate deployment, reduce costs, and deliver greater confidence in flight-critical AM components.

Redshred

From Documents to Data – Built from the ground-up to be API-first, Redshred offers your team a powerful solution that goes beyond just text and object recognition. Get to Higher ValueWork Faster – Data scientists and developers can use unstructured data to build new models and smart applications without the hassle of extracting, cleaning, and aligning content from documents.

- Extract Layers of Interconnected Metadata.

- Structured & Searchable.

- Collaborative & API-First

Focus Area: Business IT and Analytics

Contact

Chris Root

chris.root@redshred.com

619-750-2390

www.redshred.com

Transforming Unstructured Data into Actionable Intelligence

Problem Statement:

Systems engineers, developers, and data scientists currently face significant bottlenecks when attempting to extract structured, queryable “knowledge packets” from unstructured data sources. These processes often require:

- Manual extraction

- Time-intensive annotation

- Resource-heavy quality assurance

Technology Solution Statement:

Redshred specializes in maintenance and sustainment transformation with proven use cases:

- System Manuals: Access Alerts, Diagrams, and Tables; Custom Language Models; Structured & Semantic Search

- Fault Trees: From Static Documents to Interactive Applications; Link to Historical Maintenance Records; Simplified Navigation

- Procedure Steps: Identify Tools, Parts, and Consumables; Flatten Hierarchical Procedures; Easy Checklist Extraction

- Link Content: Navigate Through Entities; Attach Custom Metadata; Cross-Reference Pages Across Documents

Our API-First Platform makes it easy to integrate with existing platforms & technologies

- Easy Document Upload API: Simply upload your documents into Collections on RedShred

- Tailored Configuration: Targeted extraction and enrichment tailored to your document types

- Supports Common Formats: Scanned Images, PDFs, Spreadsheets, Plaintext, etc.

- Developer Friendly: API endpoints return structured JSON data for easy integration

Benefits Statement:

Redshred dramatically reduces the time and resources required for these essential data transformation processes, providing:

- Accelerated access to actionable intelligence

- Reduced manpower requirements

- Enhanced data utilization capabilities

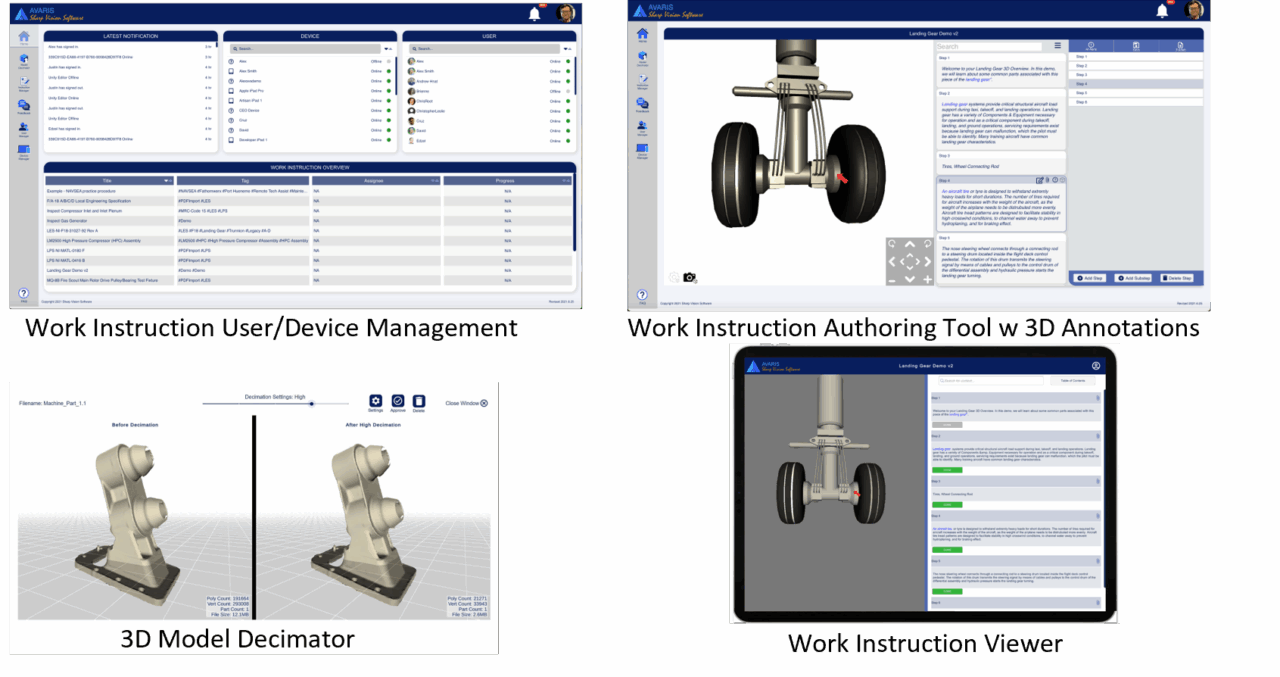

Sharp Vision Software

Sharp Vision Software develops innovative solutions for training, engineering, manufacturing, maintenance, and field service using cutting-edge technologies to clients in defense, healthcare, pharmaceutical, aviation, power, and oil & gas industries with customers including U.S. Army, Navy and Air Force, Uniformed Services University, General Electric, Pfizer, ExxonMobil, Intel, and CAE.

Focus Area: Workforce Development/Visualization

Contact

Win Liu

win.liu@sharpvisionsoftware.com

443–527–7889

AI-Powered 3D Model-Based Work Instruction and Tech Manual Authoring/Viewing Tool for MRO

Problem Statement:

- Traditional technical documents that describe overhaul and repair processes for aircraft and aircraft components are limited in the ways technical information can be conveyed from engineers to artisans.

- Parts with complex features or many of a similar feature can be difficult to describe using conventional two-dimensional diagrams and/or images.

- The current procedure for revising technical documents is cumbersome and can often delay small, but important updates from being incorporated into new revisions quickly.

Benefits Statement:

- Utilization of 3D scanned and 3D modeled parts to further enhance ability to describe a part, feature, or process.

- More efficient knowledge transfer from engineer to artisan – less chance for artisan misunderstanding and error.

- Quick feedback/question tools for simple questions from artisans to engineers that prevents slow down of production.

- Visual-based training for new artisans, also helps to capture ‘tribal knowledge’ of experienced artisans .

- Easily convert existing ‘paper’ technical documents into digital work instructions.

- Quickly deployable to DoD sustainment sites for use in bulletins, AFCs, training-aids, and Maintenance, Repair, and Overhaul (MRO) type work operating integrated within PLM systems or as a standalone system.

Technology Solution Statement:

- Enhance existing technical document into a 3D model based digital work instruction format or draft completely new digital work instructions from the ground-up using AVARIS.

- Implement 3D scanned or 3D Computer Aided Design (CAD) models into work instruction steps to enhance understanding of complex parts and processes.

- Condenses 3D models, images, diagrams, data tables, and text information into an easy-to-navigate window that can easily be accessed by artisans on a tablet – which otherwise may be a 100+ page PDF.

- Utilizes rapidly growing network of digital content across the DoD to enhance work instruction understanding.

Shipcom AI

Shipcom AI is a mission-driven technology company delivering AI-powered logistics, resilient edge computing, and operational decision support for the Department of Defense and allied forces. By combining data from IoT sensors with advanced artificial intelligence, Shipcom transforms raw information into actionable insights that drive real-time decision-making across disconnected and contested environments.

Our capabilities are delivered through four integrated solution portfolios:

- SMART.AIoT™ (Shipcom Material and Asset Real-Time Tracking): Fusing IoT sensors, edge AI, and secure networks, SMART.AIoT provides real-time visibility into critical assets and materials.

- SAMOA™ (Shipcom Asset and Material Operations Availability): SAMOA delivers enterprise-level insights into asset readiness and material availability.

- SQC5ISR™ (Shipcom Quantum C5ISR): A tactical AI micro cloud built for the edge, SQC5ISR empowers warfighters with automatic target recognition, real-time sensor fusion, and distributed command and control.

- SELO™ (Shipcom Edge Logistics Operations): SELO automates logistics and sustainment workflows at the tactical edge.

AI-powered Logistics

Problem Statement:

Modern military operations face critical challenges in maintaining asset visibility, logistics readiness, and decision speed across contested, disconnected, and data-denied environments. Traditional systems lack the agility, interoperability, and real-time intelligence needed. Without timely data integration from IoT sensors and adaptive AI, forces operate reactively—leading to increased downtime, delayed resupply, and degraded mission effectiveness.

Technology Solution Statement:

Shipcom AI delivers an integrated suite of platforms—SMART.AIoT, SAMOA, SQC5ISR, and SELO—that combine IoT sensor data

with advanced AI, edge computing, and secure communications. These technologies provide real-time asset tracking, AI-powered analytics, resilient C5ISR, and automated logistics across the full mission lifecycle. Our modular, sovereign solutions are designed to operate in DIL conditions and align with DoD initiatives —ensuring decision dominance at the tactical edge.

Benefits Statement: