Altair

Focus Area: Enhanced Inspection

Contact

Harry Kennedy

hkennedy@altair.com

201-429-5850

Altair Engineering, Inc. delivers over 180 software tools addressing multi-physics modeling & simulation (M&S), high-performance computing (HPC), and data analytics to solve the most complex engineering challenges. Our patented SaaS-like, consumption-based licensing model ensures cost-effective access to the entire Altair product portfolio while enabling open architecture integration and API connectivity. Altair’s Enterprise Solutions Group provides workflow automation, enterprise integration, and custom applications, fully embracing agile methodologies.

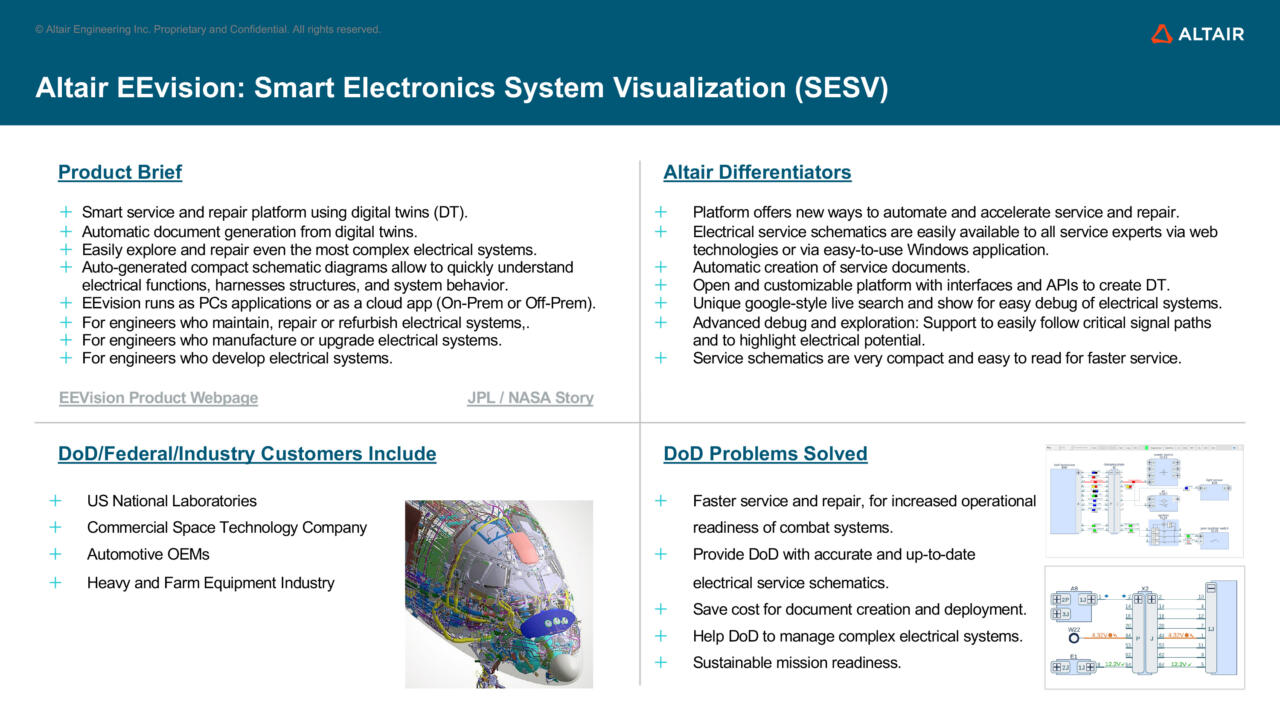

At Warner Robins AFB, Altair will present EEVision, a smart electrical system visualization tool designed to create interactive, digital-twin-based visualizations of electrical/electronic systems from legacy schematic data, including PDF-based Technical Orders. EEVision streamlines fault isolation, reduces downtime, and improves maintainability by eliminating manual schematic interpretation.

Primary customers include the Department of Defense, defense OEMs, aerospace manufacturers, and electronics companies requiring advanced design verification, sustainment, and reverse engineering solutions.

EEvision

Problem Statement:

Technicians rely on outdated, static schematics that are hard to interpret and often inaccurate. This leads to longer downtimes and costs associated with repairs and maintenance.

Technology Solution Statement:

EEVision’s workflow integrates advanced visualization, automated DRC, and AI-enhanced data handling to deliver accurate, interactive schematics from legacy data. It connects directly to simulation tools for rapid component/system analysis, enabling maintainers to pinpoint issues quickly, verify designs, and streamline reverse engineering.

Benefits Statement:

EEvision reduces troubleshooting time and maintenance cycles to increases asset availability and operational readiness. This enables rapid reverse engineering and integration with existing sustainment workflows.

Aptima, Inc.

Focus Area: Energy, Environmental, Health, and Safety

Contact

Kevin Durkee

kdurke@aptima.com

937-490-8010

Aptima, Inc. is a small business engineering firm, headquartered in Woburn, Massachusetts, specializing in innovative R&D for various DoD organizations with a focus on end-user applications to augment human performance. Aptima’s expertise is in creating effective end-user solutions through the integration of wearable sensors, secure communications, and intuitive user interface design. Aptima’s work aims to seamlessly blend new technologies with end-users’ natural behaviors and environments, leading to improvements in job performance and decision-making capabilities. Among Aptima’s leading advancements within the DoD are its health/safety monitoring and atmospheric detection systems, which have a broad spectrum of applications from personal health management to industrial workforce safety monitoring. Aptima’s experienced team of scientists and engineers continuously pushes the envelope of human-centric technology, striving to translate theoretical concepts into practical solutions that address the real-world challenges faced by individuals and communities. Aptima prioritizes positive and active collaborative relationships with its project stakeholders, fostering partnerships that propel the collective pursuit of technological excellence and meaningful impact.

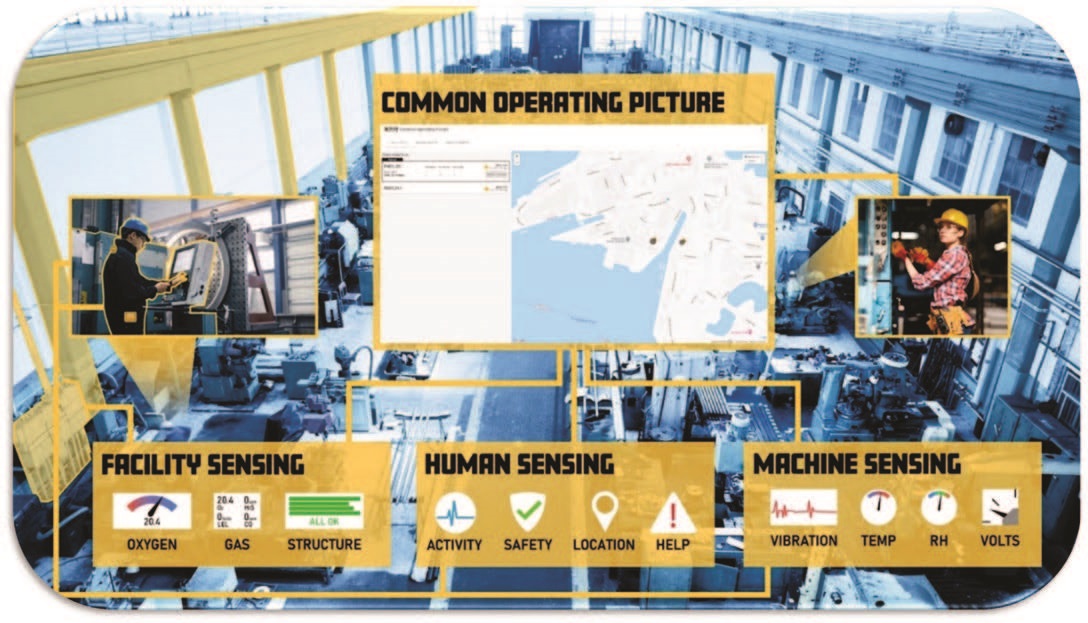

Confined Spaces Monitoring System

Problem Statement:

Gas-free engineering and confined spaces safety management is a very challenging problem facing DOD maintenance. Existing OSHA regulations require frequent gas measurements and roughly 1:1 safety attendant to worker ratios for monitoring confined spaces, leading to high manpower costs and operational inefficiencies.

Technology Solution Statement:

CSMS shifts confined space monitoring practices from manual to sensor-based automated procedures, enabling remote safety attendants to continuously monitor areas and personnel. CSMS provides attendants with enhanced situational awareness, allowing a single individual to safely monitor multiple areas and workers supporting prompt alerting of emergency personnel when needed. Through area-based and human-worn sensors, CSMS continuously monitors areas and workers' conditions, offering automated alerts for concerning events, thereby improving safety, compliance, and operational efficiency in DoD maintenance environments.Benefits Statement:

CSMS bolsters depot efficiency by minimizing costs and manpower for confined space monitoring, aiding in accelerating production schedules and mitigating weapon system availability delays. The benefits are threefold: (1) Enhanced Safety: faster, automated problem detection; (2) Improved Organizational Efficiency: significant reduction in labor hours for monitoring confined spaces; (3) Augmented Compliance: better adherence to OSHA regulations via digital, continuous, and semi-automated logging of confined spaces and entries, making CSMS a scalable, data-secure solution for various DOD applications.Blue Yonder Defense Solutions

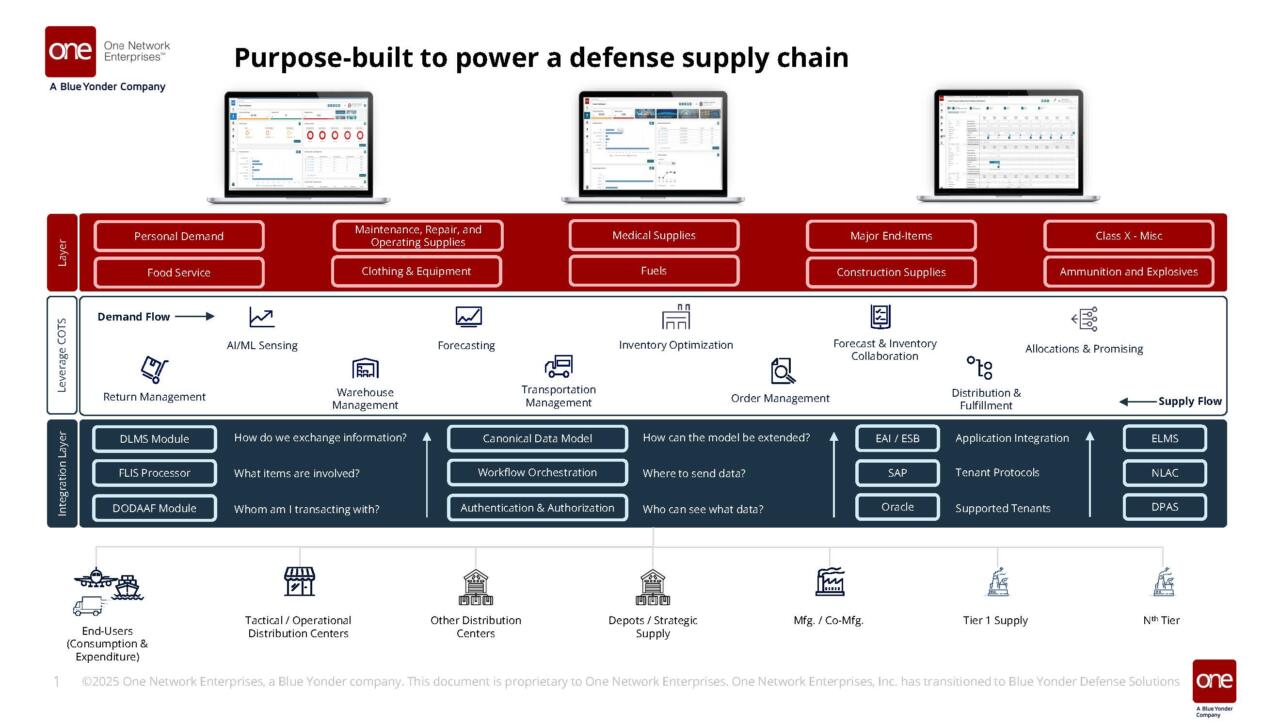

Focus Area: Business IT and Analytics

Contact

Aaron Whitlock

awhitlock@onenetwork.com

423-218-6051

In today’s dynamic environment, effective supply chain management is crucial to achieving our nation’s strategic objectives. Blue Yonder Defense Solutions (formally known as One Network Enterprises) is leading the way in revolutionizing supply chain operations and the organic industrial base by focusing on a single solution for multi-tier and multi-enterprise collaboration. This includes areas such as supplier inventory, forecast, capacity, schedule, and order collaboration. Our approach leverages seamless integration and a robust foundational supply chain network to enhance efficiency, agility, resilience, and sustainment.

Our solutions provide real-time visibility into multi-tier supplier inventory, enabling better stock management and reducing excess inventory. By facilitating collaborative forecasting, we align suppliers and manufacturers on-demand projections, reducing errors and enhancing demand planning accuracy. Blue Yonder Defense Solutions tools enable collaborative capacity planning, allowing DOD activities to identify bottlenecks and optimize production schedules. Our platform enhances scheduling and order management, reducing lead times and improving order accuracy through synchronized collaboration.

Redefining Outside-In Planning in Defense Supply Chains

Problem Statement:

In today’s dynamic environment, the Defense Organic Industrial Base faces significant challenges in achieving efficient and resilient supply chain operations. The lack of a unified solution for multi-tier and multi-enterprise collaboration hampers the ability to maintain optimal stock levels, align supply with demand, and ensure timely order fulfillment to meet mission requirements. This fragmentation leads to inefficiencies, increased costs, and reduced responsiveness to warfighter demands.

Technology Solution Statement:

Blue Yonder Defense Solutions enhances supply chain efficiency and resilience for the Defense Organic Industrial Base. Multi-tier and multi-enterprise collaboration delivers real-time visibility into supplier inventory, collaborative forecasting, capacity planning, and synchronized scheduling. With seamless integration and a flexible foundational supply chain network, the Department of Defense can optimize stock levels, align supply with demand, and ensure timely order fulfillment. End-to-end supply chain visibility and collaboration enhances agility, reduces costs, and improves responsiveness to warfighter demands while improving audit posture.Benefits Statement:

- “Shared Investment” benefits all Defense organizations

- Solution Never Goes Legacy, reducing sustainment costs while delivering modernizations.

- Rapid Configuration and deployed “your way”

- Flexible integration to current legacy/ERP and DOD systems.

- Fully supported with Deployed Operations for D-DIL/Contested environments as well as garrison warehouse, flightline, magazine, and physical operations otherwise outside of service areas.

- AI Enabled Control Tower provides visibility and actionability on real time data.

- Highest auditability results across DOD.

Brighton Science

Focus Area: CBM+/Predictive Maintenance

Contact

Madison Riddell

mriddell@brighton-science.com

513-254-2848

Brighton Science is the global leader in surface quality control for adhesion-critical manufacturing. Our flagship technology, the Surface Analyst, delivers rapid, quantitative, and non-destructive surface cleanliness measurements directly on the production floor or in the lab. By enabling real-time verification of surface preparation before bonding, coating, or sealing, we help manufacturers eliminate costly adhesion failures, improve yield, and maintain consistent quality. Our customers span high-reliability industries including aerospace, automotive, medical device manufacturing, electronics, and energy — sectors where surface preparation is mission-critical and failure is not an option. Brighton Science solutions integrate seamlessly into quality systems, from R&D to high-volume production, and are trusted by engineers, quality managers, and production teams worldwide to ensure optimal adhesion performance without guesswork or destructive testing.

Surface Analyst 3001

Problem Statement:

Manufacturers in aerospace and other high-reliability industries face costly adhesion failures caused by undetected surface contamination and inconsistent preparation methods. Traditional verification often relies on destructive, time-consuming tests that delay production and provide limited insight. Without a fast, quantitative, and non-invasive way to confirm surface readiness in real time, teams risk rework, scrap, production delays, and compromised product performance.

Technology Solution Statement:

The Surface Analyst uses patented water contact angle measurement technology to instantly verify surface cleanliness and readiness for bonding. Portable, non-destructive, and easy to operate, it provides real-time, quantitative data at any point in production. This empowers manufacturers to detect contamination, validate preparation processes, and maintain consistent adhesion performance without slowing operations.Benefits Statement:

By enabling rapid, non-destructive surface verification, the Surface Analyst dramatically reduces adhesion-related failures and associated costs. Manufacturers gain consistent, repeatable quality control across processes, locations, and teams. Early detection of contamination minimizes rework and waste, while real-time measurement increases process yield, speeds production, and enhances customer confidence. The technology replaces destructive tests with a simple, portable, and highly reliable tool, ensuring surfaces are always prepared for optimal bonding and coating performance.COAST Autonomous

Focus Area: Reliability Improvement (Hardware)

Contact

Aimie Nghiem

anghiem@coastautonomous.com

626-838-2469![COAST-COMBINED[40][72][89]](https://ncms.org/wp-content/uploads/2025/08/COAST-COMBINED407289-scaled.png)

COAST Autonomous tailors self-driving technology for industrial, military, and private environments—settings where safety and efficiency are mission-critical. With over 30 years of experience, COAST breaks the barriers of traditional automation, delivering mobility solutions for airports, railroads, ports, and demanding 3PL operations – places where the work is often dangerous, dirty, or dull. COAST harnesses its US Patented, best-in-class technologies to offer safe, efficient, flexible, and cost-effective solutions to bring actionable autonomy to real-world challenges. Its adaptable, sensor- and vehicle-agnostic architecture resolves issues like weak signals, human fatigue, and GPS outages, while continuously learning from live operations and user feedback to optimize performance for each site.

COAST’s hard tech integrates state-of-the-art artificial intelligence, advanced robotics, and a robust autonomous platform, enabling a broad range of applications, including autonomous FOD sweeping, perimeter security, and seamless vehicle fleet management. COAST’s acclaimed Command and Control (C2) system orchestrates both COAST and third-party vehicles and has been proven out by the successful Airfield Autonomy Initiative (AAI)-Next. This groundbreaking program—developed in partnership with the FAA, NARTP, USTRANSCOM, and AMC—is helping pave the way for autonomous ground operations on active commercial and DOD airfields.

Reliability Improvement (Hardware)

Problem Statement:

COAST tailors autonomous vehicle solutions addressing limitations in workforce, network access, and safety. Our technology overcomes challenges like weak signals, human fatigue, and GPS failures.

Technology Solution Statement:

COAST has developed a proprietary 6-Level Autonomous Vehicle (AV) system that includes mapping, localization, robotics, artificial intelligence (AI), fleet management, and supervision. COAST’s AV System is designed for safety first and is optimized for the user experience. All COAST vehicles have built-in redundancies and will always be able to stop safely. COAST vehicles analyze the environment to provide optimum safety for passengers, pedestrians, and any other vehicles. Using off-the-shelf perception sensors and electronics allows COAST to offer an affordable and flexible solution.Benefits Statement:

COAST's adaptable technology sets a new safety standard and blueprint for vehicle interconnectivity. Through client collaboration, initial inquiries evolve into scalable, impactful solutions. COAST use case solutions range from autonomous transportation UTVs to inventory drones to campus shuttles. COAST streamlines operations, enhancing efficiency and safety in autonomous vehicle utilization. By employing appropriate vehicles at appropriate speeds, COAST's solutions expand beyond original applications, creating a versatile platform for diverse autonomous operations. This approach not only meets immediate client needs but also paves the way for broader implementation of interconnected autonomous systems across various industries.Cybernet Systems Corporation

Focus Area: Enhanced Inspection

Contact

Kevin Tang

ktang@cybernet.com

734-668-2567 x131

Cybernet Systems Corporation, founded in 1988 in Ann Arbor, Michigan, is a research, development, and production company dedicated to advancing human performance through technology. As a small business with deep expertise in engineering and innovation, Cybernet has established itself as a trusted partner for the U.S. Department of Defense, other government agencies, and commercial enterprises worldwide.

Since its founding by Dr. Heidi Jacobus, Cybernet has focused on creating solutions that bridge the gap between humans and technology, working toward seamless interaction with systems and devices. Over the past three decades, the company has completed more than 400 Department of Defense contracts and numerous commercial projects, delivering sophisticated prototypes, systems, and services on time and on budget. Cybernet’s impact spans defense, medical, and commercial markets, with proven success in converting cutting-edge research into viable, real-world products.

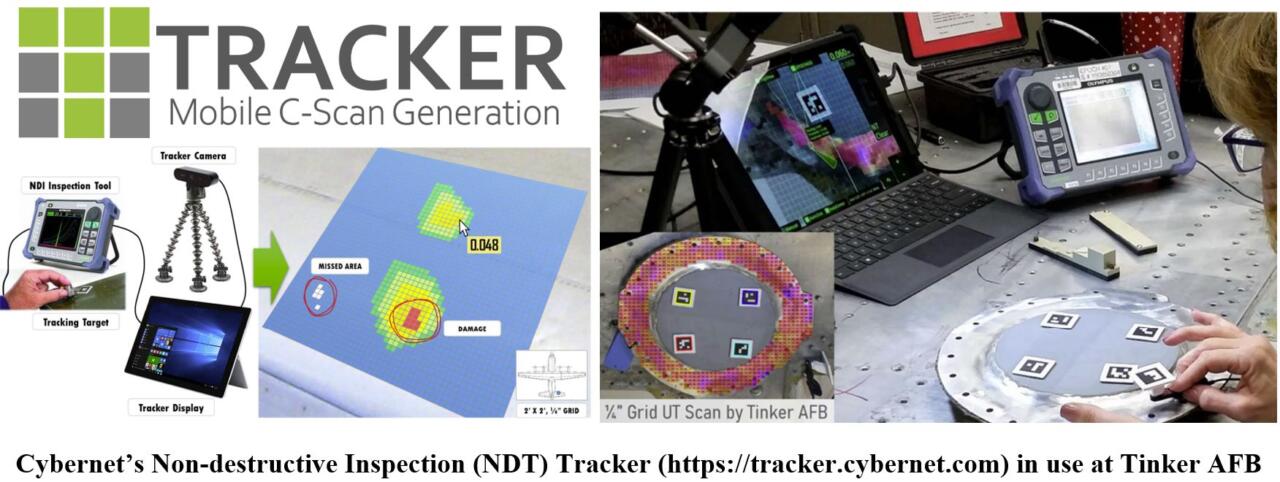

NDI Tracker for Mobile C-Scan Generation

Problem Statement:

Ultrasonic (UT) grid inspections, widely used by aircraft Maintenance, Repair, and Overhaul (MRO) facilities to map corrosion and verify remaining thickness, are slow, tedious, and labor-intensive. Typically, 0.5″ or 0.25″ grids are hand-drawn on surfaces or paper, requiring two inspectors to coordinate readings and record them manually. The resulting numerical grid lacks visual context, relying on imprecise drawings and descriptions to locate inspection areas. Miscommunication between inspectors and engineers often leads to re-inspections, causing unscheduled maintenance costs and delays.

Technology Solution Statement:

The U.S. Air Force and Cybernet Systems Corporation developed the NDI Tracker, a mobile, camera-based tool that halves UT grid inspection labor by reducing staffing from two inspectors to one. Using patent-pending AutoClick Combo-Filtering, it auto-selects accurate readings, cutting average per-cell time from 20 to 4 seconds - a 5x efficiency gain. By eliminating hand-drawn grids and providing color-mapped C-Scan reports, the Tracker prevents re-inspections, accelerates turnaround, and boosts throughput. It operates from 0.5–5 ft, covering 4×4 ft areas extendable via leapfrogging.

Benefits Statement:

The NDI Tracker delivers measurable benefits to the DoD by increasing aircraft availability and mission readiness through faster maintenance cycles and reduced sustainment costs. By cutting manpower needs and improving inspection accuracy, it enhances both efficiency and trust in results. Digital reporting eliminates delays from miscommunication, while field-proven performance across Air Force bases and major MROs validates its reliability. Lightweight, portable, and intuitive, the system is mission-ready, supporting deployability and global operations while boosting overall maintenance throughput.Edlore

Focus Area: CBM+/Predictive Maintenance

Contact

Javid Vahid

javid@edlore.com

949-690-2245

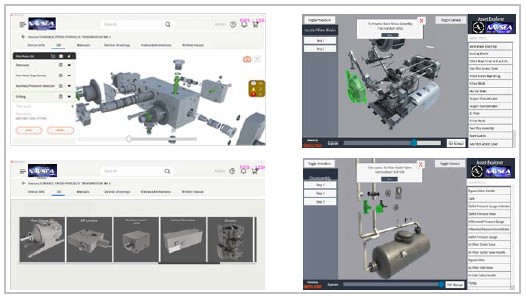

Edlore is a pioneer in AI/ML and 3D technological solutions, reshaping industry standards with its interactive manuals and wearable device integrations. Our patented AI-driven platform transforms complex technical orders into digestible, contextually relevant insights, streamlining operations. With state-of-the-art mobile and wearable technology, professionals achieve access to crucial data, ensuring efficiency and precision. Our platform also encompasses a robust Work Order Management system, enhanced by asset tracking and multimedia attachments, facilitating seamless operations and maintenance processes. At Edlore, we blend innovation and practicality, consistently delivering excellence in an ever-evolving technological landscape.

Edlore AI-On Prremise server with 3D parts identification

Problem Statement:

Despite the rapid advancement in industrial and technical operations, complex equipment service and maintainers often grapple with cumbersome manuals, scattered asset data, and lack of real-time expert assistance. This disjointed information flow increases operational downtime and raises the margin for error.

Technology Solution Statement:

Edlore introduces a unified technology suite designed for the modern maintainer. Leveraging AI's power, we've transformed dense manuals into interactive, 3D-guided insights that intuitively provide the right information at the right time. Our platform, optimized for desktop, mobile and wearable devices, ensures hands-free, on-the-go access to these insights, minimizing downtime. Furthermore, with our real-time Remote Expert Video Chat, professionals are never alone in the field, always having a lifeline to expert assistance. Paired with a comprehensive Work Order Management system and dynamic asset tracking, Edlore's solution streamlines operations. A simple scan of a device will show all manuals, drawings, videos, pictures, LOTO Safety, PM procedures, Remote Expert Video Chat and 3D/AR explosive view with parts metadata that allows you to even send the part to be printed on a 3D printer.

Benefits Statement:

Empowering maintainers with immediate access to AI-enhanced, 3D interactive guidance, reduces operational errors and downtime. By unifying knowledge, expertise, and real-time tracking within a mobile and wearable interface, we ensure every task is executed with precision, speed, and confidence. The benefits of using Edlore are:- More efficient on-board service and repair.

- Never miss regular PM Maintenance.

- Access to device parts metadata and ability to possibly print the component on board.

- Gathering field data from service and repair.

- Mobile and handsfree operation.

FLX Solutions

Focus Area: Enhanced Inspection

Contact

Matt Bilsky

matt@flxsolutions.com

215-620-2116FLX Solutions develops advanced robotic systems that enhance mission readiness and safety by minimizing maintenance disruptions across defense operations with expanding applications in industrial, transit, and construction sectors.

The FLX BOT is a compact, articulating snake-like robot that transforms inspection and maintenance for defense and industrial environments. It is 1″ in diameter and can navigate confined or hazardous spaces on ships, bases, and aircraft. Operated by a single technician via handheld control or extension pole, it reduces labor and improves safety.

Its modular design includes interchangeable links with advanced cameras and sensors for autonomous obstacle avoidance. Plug-and-play end effectors, such as 4K, 360°, and 3D cameras, NDT sensors, thermal imaging, leak detectors, & sprayers enable rapid adaptation for diverse tasks.

FLX BOT: Intelligent Robot for Tight Space Inspections & Maintenance

Problem Statement:

Maintenance and DOD technicians face major challenges inspecting and sustaining critical equipment on aircraft, ships, and remote bases. Many areas are confined, hidden, or too dangerous to access safely. Tight turnaround times and unsafe conditions increase risk. Current methods rely on costly teardowns and hazardous scaffolding. There is a need for high-resolution inspection tools that access hard-to-reach spaces efficiently.

Technology Solution Statement:

The FLX BOT is a handheld, snake-like robot that navigates confined spaces in aircraft, ships, and bases with minimal training. Its slim, modular design uses interchangeable links with cameras and sensors for autonomous movement. Swappable end effectors—360°, 3D, thermal cameras, NDT tools, grippers, and more—enable diverse maintenance tasks. Lighter, smaller, and more flexible than robots costing 10x more, it fits in a briefcase. Programs are underway across defense, transit, and industry.Benefits Statement:

FLX BOT improves inspection quality while reducing maintenance damage, injuries, and costs. Navy pilots showed 90% savings in time and expense for hard-to-reach areas. It decreases downtime through efficient preventative maintenance and faster recovery. Technicians stay safely on the ground when inspecting elevated spaces. The robot collects sensor data for predictive maintenance and documentation—even at the front lines. With strong ROI and lower QA/QC costs, FLX BOT enhances safety, speed, and operational readiness.G.C. Laser Systems, Inc.

Focus Area: Coating and Corrosion Prevention

Contact

Magdalena Dajnowski

magdalena@gclasers.com

844-532-1064

G.C. Laser Systems Inc. is an American laser cleaning system manufacturer and a CWOSB with headquarters in Illinois. Our unique and globally patented laser cleaning technology is proudly designed and made in the USA. This proprietary technology was initially developed to clean cultural heritage buildings and artifacts with unmatched precision, and has evolved into many heavy duty industrial and DoD applications. From making our own scan heads and optics to fabricating our systems with durable stainless steel and powder coated aluminum to endure humid and corrosive environments, we specialize in delivering off the shelf and custom bespoke laser ablation tools that can work during all four seasons worldwide. Notable cultural heritage projects that have utilized our laser ablation technology include the US Supreme Court, the US Senate Building, Notre Dame, Sydney Harbor Bridge, Capitol of Maryland, the Egyptian Obelisk in Central Park, the Smithsonian, and buildings and monuments worldwide. On the industrial side our technology is used for rust removal, paint removal, chloride removal, surface prep, hydrocarbon removal, radiation decontamination, lead abatement, and various other industrial applications that demand precision and efficiency. Branches of the DOD such as the US Army, the US Coast Guard, and the US Air Force use our laser equipment to maintain and service valuable assets.

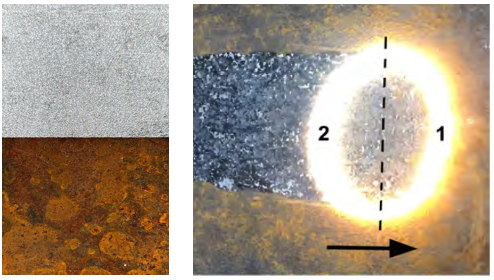

Laser Cleaning Technology

Problem Statement:

Removing corrosion and coatings from a variety of surfaces can be challenging and the process of abrasive corrosion removal can wear down the thickness of the assets being cleaned, reducing its useful service life, as well as pose environmental concerns with traditional blasting media and chemical stripping containment. Traditional cleaning techniques rely on consumables and have a lot of clean up and disposal costs.

Technology Solution Statement:

G.C. Laser Systems offers environmentally friendly, durable, and compact portable laser systems for removing rust, paint, coatings, and contamination from surfaces. Built with an in depth understanding of the photomechanical, photothermal, and photochemical effects that laser pulses can have on a surface, our highly tunable systems offer unmatched precision, control, and repeatability with laser ablation cleaning and surface prep. Corrosion, salts, and coatings are removed from metal surfaces without causing any damage or thickness loss to the substrate.Benefits Statement:

- Environmentally friendly.

- No consumables.

- No damage to substrate being cleaned.

- Less heat on surface than other laser ablation systems.

- Patented high speed and hot-spot-free laser cleaning.

- The beam never stops in one place and rotates at high RPM.

- 2-3 times faster cleaning than competitors.

- Designed and made in the USA.

- Made for use in humid and corrosive environments.

Grey Gecko, LLC

Focus Area: Coating and Corrosion Prevention

Contact

Joe Laws

joe@greay-gecko.com

757-813-4928

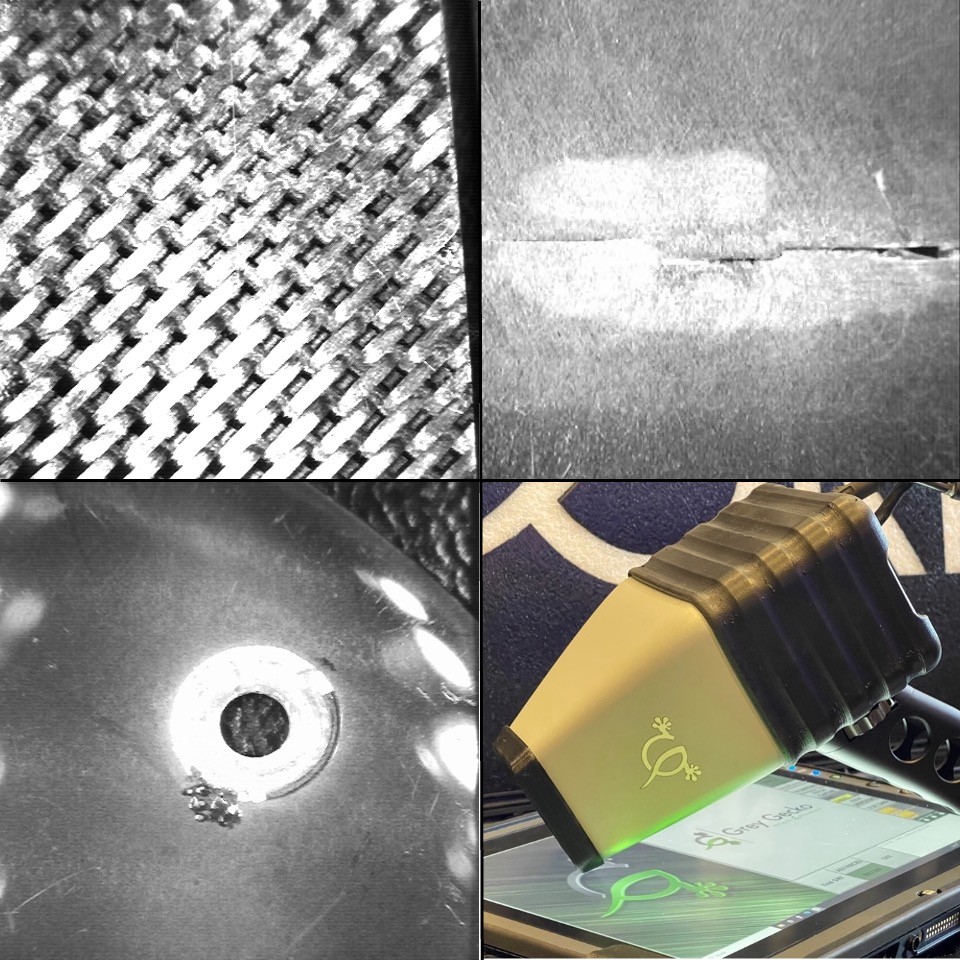

The Grey Gecko Real-Time Inspection Tool (GRIT) 125v2.50 is a patented corrosion detection device that optimizes Non-Destructive Inspections and offers a “first look and early find” capability, saving time and money. Developed and refined with feedback from the U.S. Coast Guard, Navy, Army, and Lockheed Martin, the deployable, lightweight, battery-operated device sees-through paint to the substrate. The GRIT can reduce aircraft downtime by 25% and inspection labor by 50% on commercial, strategic airlift, executive transport, aerial refuelers, C2ISR platforms, and 3rd/4th generation tactical and rotary-wing aircraft.

In Q4 2023, the Naval Air Warfare Center Aircraft Division’s Materials Engineering and Structures Engineering branches and the Jacksonville Materials Engineering Laboratory investigated and demonstrated the GRIT’s efficacy. Ideal applications are: uncoated, chromate and polyurethane systems, CARC, and epoxy non-skid, up to a thickness of 20mils. Eye-safe and FCC-compliant, the GRIT is equally effective on any substrate type with no PPE or PMEL. Recently, the GRIT system detected a crack on the rear horizontal stabilizer of a U.S. Coast Guard C-27J Spartan aircraft and two additional cracks that had evaded previous NDI inspections. This real-time inspection prevented the need for chemically removing the coating system.

Grey Gecko Real-Time Inspection Tool (GRIT)

Problem Statement:

Aircraft corrosion costs the DOD $20 billion annually while simultaneously performing critical airframe life extension programs to meet increasing national security requirements. Current NDI inspections are labor intensive, non-targeted, and inconsistent, relying heavily on the technician’s availability and tradecraft. The DOD needs a cost-effective, deployable, intuitive, and consistent inspection device.

Technology Solution Statement:

The GRIT system is a deployable corrosion inspection device that offers live imaging through aircraft coatings to the substrate at a depth of 20mils. It is a field-proven, commercially available device that streamlines existing inspection processes by directing technicians to specific areas of concern. It is equally effective on all materials and works globally at temps between 0-120°F, the GRIT's design and features have been optimized through continuous maintainer and program manager feedback.Benefits Statement:

The GRIT offers a fast ROI through labor, inspection and mitigation savings. With an ROI of five months at the intermediate level and two months at the MRO level, the GRIT optimizes technicians' "time-on-job," saving a minimum of 50% in labor. Additionally, the GRIT provides early corrosion detection and reporting, enabling fleet managers to proactively address maintenance needs, ensuring operational readiness and fleet resiliency.Hexagon Manufacturing Intelligence, Inc.

Focus Area: Enhanced Inspection

Contact

Jeff Elmer

jeffrey.elmer@hexagon.com

732-832-6809

Hexagon is a global leader in digital reality solutions, combining sensor, software and autonomous technologies. We are putting data to work to boost efficiency, productivity, quality and safety across industrial, manufacturing, infrastructure, public sector, and mobility applications. Our technologies are shaping production and people-related ecosystems to become increasingly connected and autonomous – ensuring a scalable, sustainable future. Hexagon’s Manufacturing Intelligence division provides solutions that use data from design and engineering, production and metrology to make manufacturing smarter. For more information, visit hexagon.com/mi.

Hexagon – Portable Scanning, probing, NDT/NDI, and much more.

Problem Statement:

Technicians face the challenge of requiring multiple devices to perform a variety of quality assessments, from non-destructive testing (NDT) to laser scanning and probing. This complicates the workflow, and escalates costs and training requirements. The need is for a singular, versatile system that can seamlessly transition between NDT, high-resolution laser scanning, and precise probing without sacrificing accuracy, efficiency, or functionality.

Technology Solution Statement:

A multifunctional tool like Hexagon's Absolute Arm could resolve multi-tool complexities by consolidating quality assessment needs into one integrated solution, thereby optimizing the quality control process. A 3D scan with the Absolute Scanner can be used on small to large objects with Hexagon’s AS1 and AS1-XL made for the Absolute Arm.

Benefits Statement:

- High accuracy measurements, with continual support.

- NDT Sensor

- For most Metals

- Capable to resolve volumetric flaws of 0.5mm and smaller

- Compliant with most codes: ASTM, ASME, etc…

- For most Welds

- Capable of resolving through-wall extensions of 5-10%T

- Compliant with most codes: ASTM, ASME, AWS, EN/ISO, API

- For most Composites

- CFRP / GFRP

- Easy to resolve 2.5mm flaws (and smaller)

- AS1 / AS1-XL Absolute Laser Scanner

- Complete digitizing from small to very large parts

Industrial Coating Services, Inc.

Focus Area: Coating and Corrosion Prevention

Contact

Randy Johnson

rjohnson@ics-inc.com

612–839–4653

Industrial Coatings Services, Inc. – Automation Solutions, specializes in providing cutting-edge Automated paint system technologies tailored to meet the diverse needs of manufacturing processes and the modernization of these areas. We focus advanced rotary paint atomizers and generative AI to deliver superior coatings and automation applications to manufacturing platforms. The core of our operation is a commitment to delivering unmatched performance and reliability in paint application and other automation opportunities.

Through the integration of automation, we streamline and enhance production processes while minimizing humans in hazardous manufacturing areas. Our state-of-the-art robotics are equipped with advanced sensors and algorithms enabling them to adapt to changing conditions and achieve optimal results in real-time.

With our expertise and innovative approach to technology integration, we empower manufacturers across diverse industries to enhance their products’ durability, performance, and aesthetics while maximizing operational efficiency and minimizing costs.

Industrial Coatings & Automation Solutions

Problem Statement:

Streamlining painting and other production processes and minimizing human exposure to hazardous environments

- Enhancing adaptability to changing conditions through painting and other robotics and automation • Leveraging generative AI to analyze data and optimize formulation processes.

- Continuously refining solutions to meet evolving project requirements and environmental considerations.

- Maximizing operational efficiency and minimizing costs across diverse industrial settings

Technology Solution Statement:

To address these challenges, we automate repetitive painting and handling tasks, optimize workflows, while enhancing efficiency, repeatability and safety.Benefits Statement:

Our data-informed solutions have shown a 30% increase in production efficiency, 50% reduction in manufacturing defects, and 25% decrease in downtime due to painting automation. By minimizing human involvement in hazardous areas, we've achieved a 50% decrease in workplace accidents, and an increase in repeatability while meeting Mil spec requirements for paint thickness. Through these efforts, we've optimized the painting process, resulting in massive throughput gains.Markforged

Focus Area: Advanced/Additive Manufacturing

Contact

Danielle Bartholomew

danielle.bartholomew@markforged.com

215-267-7675

Markforged delivers advanced additive manufacturing solutions purpose-built for the Department of Defense, enabling rapid, point-of-need production of mission-critical parts. Headquartered in Waltham, Massachusetts, Markforged pioneered Continuous Carbon Fiber Reinforcement (CFR), producing composite parts that are lighter than aluminum yet stronger than many metals—ideal for aerospace, naval, and ground systems where strength-to-weight ratio is critical.

Through the same Digital Forge platform, DOD users can seamlessly print both high-strength composites and true metals, reducing reliance on vulnerable supply chains and cutting lead times from months to hours. The ecosystem integrates ruggedized 3D printers, advanced materials including carbon fiber, Kevlar®, Onyx, stainless steels, Inconel, and tool steels as well as secure software with digital part verification and inventory management.

3D Print Strong Parts | Carbon & Metal | Audit & Production

Problem Statement:

Adopting additive manufacturing at scale for the DOD presents challenges. First, many commands have access to entry-level or composite-only 3D printers that can produce temporary parts or prototypes, but these parts often lack the strength, durability, and certification required for long-term replacements in mission-critical applications. Second, most 3D printer acquisitions within the DOD do not include intuitive, secure software platforms, which results in underutilized equipment and a lack of continuity in AM programs.

Technology Solution Statement:

Markforged provides the DOD with a complete additive manufacturing platform capable of producing both continuous carbon fiber reinforced composites and true metals on the same system. This capability delivers lightweight parts with strength exceeding many metals, as well as fully metallic components in stainless steels, tool steels, and high-temperature alloys such as Inconel. The result is mission-ready parts suitable for both temporary and long-term use. The technology enables units to manufacture replacement components, jigs, fixtures, and end-use parts directly at the point of need, reducing lead times from months to hours. Continuous fiber reinforcement ensures structural strength and durability well beyond what conventional polymer-only printers can achieve, expanding additive manufacturing from prototyping to true sustainment.Benefits Statement:

- Continuous Carbon Fiber Reinforcement (CFR) and true metal 3D printing on the same platform produces end-use parts that meet or exceed the performance of traditionally manufacturing.

- Intuitive software and training ecosystem ensures that AM capabilities are fully adopted and sustained across units.

- Markforged University provides standardized training across the Services, along with QR-coded quick-start guides.

- Part auditing, production services, and custom engineering support, enables identification of viable candidates for additive replacement.

Perfect Point EDM

Focus Area: Advanced/Additive Manufacturing

Contact

Jim Becker

Jim@ppedm.com

Perfect Point EDM is an aerospace technology company specializing in innovative maintenance solutions that enhance safety, precision, and efficiency. Founded with the mission to transform outdated fastener removal methods, Perfect Point introduced the E-Drill—an electro-discharge machining (EDM) system designed specifically for the removal of “permanently” installed fasteners in aerospace structures.

Traditional fastener removal methods rely on twist drills and manual cutters that are time-consuming, inconsistent, and prone to damaging aircraft components. Perfect Point’s E-Drill system replaces this process with a semi-automated plunge-cut EDM tool that delivers unmatched accuracy while eliminating debris, reducing ergonomic strain, and cutting removal time by up to 20x. The E-Drill uses electrical energy to erode fastener head material without physical force, reducing therisk of damage to the airframe and technician. Implemented by both commercial and military MRO operations, the E-Drill has proven itself as a breakthrough solution for complex, high-strength fastener types, including titanium and blind bolt fasteners.

Perfect Point is committed to supporting aviation operators, OEMs, and MROs with tools that keep fleets mission-ready, reduce downtime, and protect high-value assets. Our solutions are designed with real-world maintenance needs in mind—streamlining workflows, improving consistency, and supporting technician safety across the aerospace industry.

E-Drill: The Next Generation Fastener Removal Tool

Problem Statement:

Traditional fastener removal in aerospace, unchanged for decades, is slow, labor-intensive, and often damages airframes while posing safety risks to technicians. New aircraft designs use tougher fasteners like Titanium and Inconel, exacerbating these issues and increasing downtime.

Technology Solution Statement:

The E-Drill is a handheld device that employs electro-discharge machining (EDM), a non-contact method using electrical sparks to erode tough metals like Titanium without applying force or heat to nearby structures. It operates via a three-step process: first, precise alignment to locate the fastener; second, EDM cutting to create a thin groove in the head using a controlled electrode and dielectric fluid; and third, a quick pneumatic punch to safely remove the head. This technology integrates computer controls, interchangeable guides, and a closed-loop water system to flush debris, ensuring efficiency and minimal damage in aerospace applications.Benefits Statement:

The E-Drill dramatically reduces fastener removal times by up to 20x, boosting aircraft turnaround efficiency and minimizing downtime. Its precise electro-discharge machining technology significantly reduces airframe damage and eliminates hazardous debris, ensuring cleaner operations. Enhanced technician safety is achieved by reducing repetitive motion and impact injuries.r4.ai

Focus Area: Workforce Development/Visualization

Contact

Greg Wardman, Jr.

gwardman@r4.ai

615-441-6075

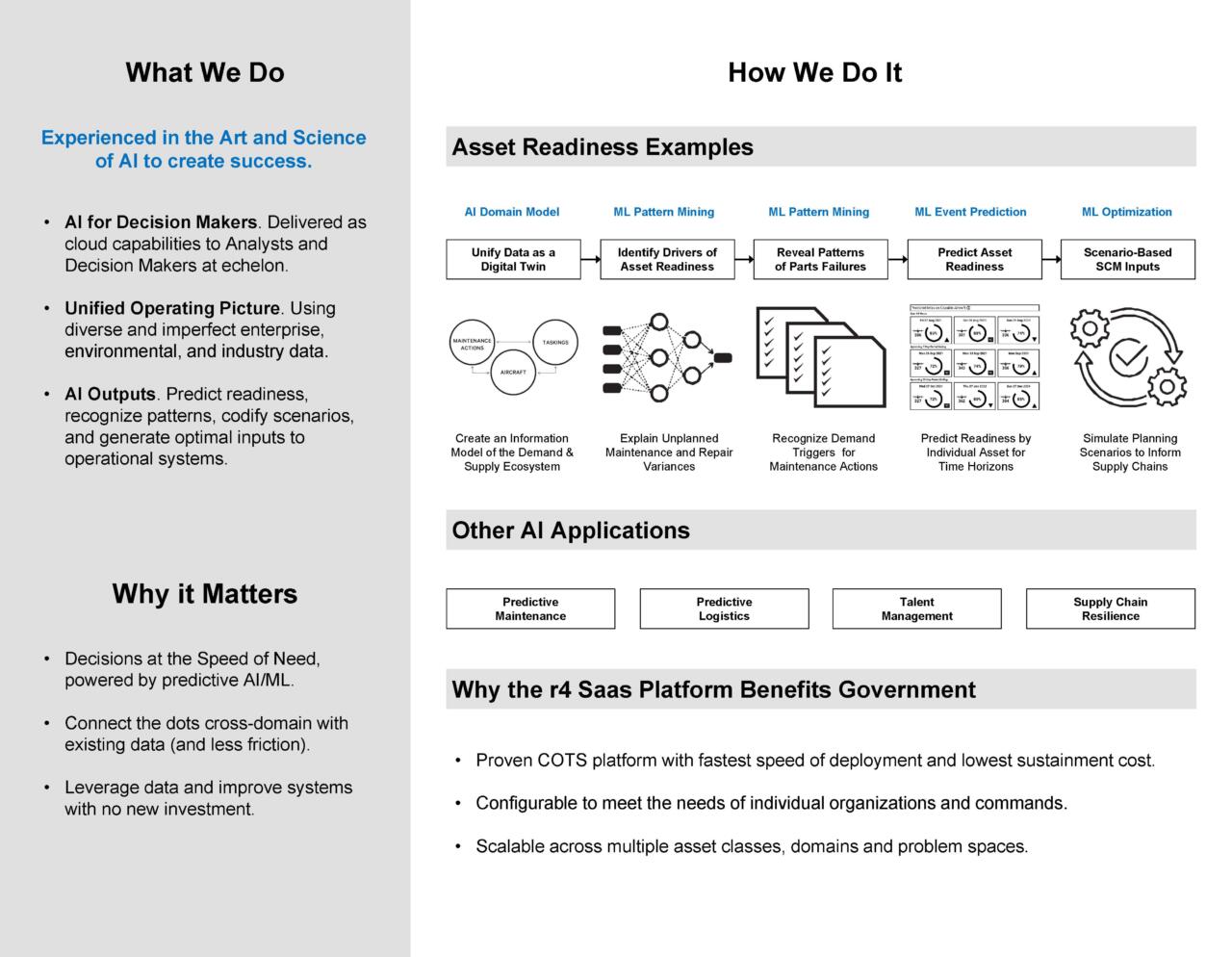

Founded in 2013, r4 Technologies is the leader in applying AI to cross-enterprise management, delivering better business outcomes as a service. r4 was created by founders of Priceline, leveraging decades of expertise in extracting profit from data.

XEM

Problem Statement:

- Total Asset Visibility

- Product Lifecycle Management

- Artificial Intelligence

- AI/ML Applications

Technology Solution Statement:

r4 XEM® is an AI solution for business users to plan together more easily, make optimal and connected decisions and take faster and aligned actions cross enterprise.

Benefits Statement:

r4 AI gets all the right hands and left hands to work together to simplify complexity and empower humans to create a better future.RGBSI Aerospace & Defense

Focus Area: Advanced/Additive Manufacturing

Contact

Tyler Rigsby

tyler.rigsby@rgbsiaero.com

937-238-2587

RGBSI Aerospace & Defense is an SBA-certified Woman Owned Small Business (WOSB) with exceptional DOD Prime Contractor qualifications. Since 2020 RGBSI A&D has been called on by OSD, DLA, DOD Military Services, U.S. allies, and coalition partners to solve weapon system sustainment issues. With a broad portfolio of DOD Prime Contracts for highly qualified expertise, RGBSI A&D has been recognized as an industry leading go-to firm for artificial intelligence, advanced manufacturing, digital engineering, model-based manufacturing, product quality, and supply chain risk management services. RGBSI A&D has distinguished themselves by working collaboratively with OSD, DLA, and DoD MilSvs through the DOD Small Business Innovative Research (SBIR) program to design, develop, demonstrate, and deliver the Digital Sustainment Platform. The DSP is the only DODI 5000.97 Digital Engineering platform certified by the DOD to operate on the DOD Secure Unclassified Networks (SUNet), providing secure fully integrated technology-enabled warfighter readiness capabilities CONUS and OCONUS in support of U.S. National Security objectives. Via SUNet, RGBSI A&D has delivered additive and advanced manufacturing capabilities at the edge of the battle space for III Marine Expeditionary Force (3MEF), Special Operations Command Europe (SOCEUR), and in direct support of major DOD joint and coalition exercises Talisman Saber and Trident Warrior. RGBSI A&D Executives have served as Chairs and Co-chairs, Invited Speakers, and Panel Members for a variety specialized topics including Artificial Intelligence, Digital Engineering, Model-based Manufacturing, Product Quality, and Supply Chain Risk Management.

Digital Sustainment Platform (DSP)

Problem Statement:

Maximize and extend warfighter core capabilities to repair and maintain weapons systems via a state-of-the-art modern, scalable, and secure IT Tool designed and developed with underlying COTS technology stack & architecture

Technology Solution Statement:

DSP is a proven, scalable suite of best-of-breed applications, tools and services for Engineering, Supply Chain, Manufacturing, Procurement, Quality and Analytics. DSP maximizes and extends warfighter core capabilities to repair and maintain weapons systems in a contested environment with limited-to-no access to resupply, IT infrastructure or networking.Benefits Statement:

- Repair and maintain weapons systems in the battlefield via COTS technology

- Collaborate throughout the Sustainment Process and Generate 3D Technical Data Packages under configuration and under control

- Ingest data from commonly used CAD platforms to provide 3D CAD Models in all available standard industry acceptable formats

- Quickly analyze, categorize, and prioritize manufacturing requirements

- Expedite certification of manufacturing processes and issuance of production part approvals

Siemens Government Technologies

Focus Area: Advanced/Additive Manufacturing

Contact

Robert Tye

robert.tye@siemensgovt.com

703-789-5409

Combining the real and the digital worlds makes it possible to seamlessly integrate the entire value chain from design to realization, while optimizing with a continuous flow of data. A true Digital Enterprise is able to harness the unlimited power of data by gaining valuable insights to make fast and confident decisions – and to create best-in-class products through efficient production.

Digital Simulation of Production

Problem Statement:

Aging infrastructure, inefficient layout and old equipment are contributing to longer maintenance times, increased costs and reduced fleet readiness.

Technology Solution Statement:

Provide a digital model to identify equipment and process solutions that increase throughput through experimentation, and further set the state for equipment procurements and facility designs that enable improved operations.Benefits Statement:

Digital model of the maintenance process: maximizes allocation of resources, provides framework for data driven optimization, maximizes workforce allocation, targets faster ROI for project investments.Universal Synaptics

Focus Area: CBM+/Predictive Maintenance

Contact

Ken Anderson

ken.anderson@usynaptics.com

801-695-1709

Universal Synaptics is the industry leader in detecting and isolating elusive intermittent faults (the primary cause of No Fault Found (NFF) test results in electrical systems) in compliance with the Department of Defense MIL-PRF 32516. The massive digital testing void that exists today with conventional scanning test equipment led to the development and deployment of the patented Portable Intermittent Fault Detector™ (PIFD™), the Intermittent Fault Detection & Isolation System™ (IFDIS™), and the Intermittent Fault Detection & Isolation System 2.0™ (IFDIS 2.0™).

Portable Intermittent Fault Detector (PIFD)

Problem Statement:

One of the major cost drivers for the Department of Defense (DOD) is the maintenance of electronics and electrical systems that control and operate a wide-ranging inventory of weapons and weapon systems. The Department spends billions per year maintaining electronics and electronic systems. One of the highest contributing causes for these costs is operationally induced intermittent faults that result in No Fault Found, Cannot Duplicate, or No Trouble Found test results, essentially false readings to the effect that there is no problem. DOD’s most recent estimate (April 2022) is that these faults add nearly $5.5 billion in non-value added costs and over 383,254 non-mission capable days annually to the cost of DOD weapons systems.

Technology Solution Statement:

The Portable Intermittent Fault Detector (PIFD) is a cuttingedge technology developed and patented by Universal Synaptics. It is MIL-PRF-32516 compliant and purpose built to detect a wide range of faults in complex electronics and electrical systems. It is an indispensable tool for engineers and technicians in various industries.Benefits Statement:

The PIFD and the Intermittent Fault Detection & Isolation System 2.0 are the only objectively proven solutions to remediate intermittent / No Fault Found.VRC Metal Systems

Focus Area: Advanced/Additive Manufacturing

Contact

Gentry Boswell

gentry.boswell@vrcmetalsystems.com

605-431-4144

VRC Metal Systems, LLC is a company founded in 2013 based on research performed at South Dakota School of Mines and Technology in collaboration with the US Army Research Laboratory (ARL) to design a hand-operable high-pressure cold spray capability. The goal of advancing this technology was to allow for simple but high-quality repairs of DOD assets either in a depot or field environment. Since its founding, VRC Metal Systems has continued to develop this technology, creating more highly portable systems as well as producing robust systems for continuous commercial operation. VRC has successfully commercialized a line of high-pressure cold spray capabilities that has successfully enabled new production and repair activities in the DoD, the energy sector, the heavy industrial sector, and in research and academia. VRC is also working with ARL and other DOD entities to advance the state of the art in High Deposition Rate Additive Manufacturing (HD-RAM) processes like cold spray additive manufacturing, wire directed energy deposition, friction stir additive manufacturing, as well as developing secondary processing techniques for these processes like localized thermal processing, secondary deformation processing, or even machining. VRC is a full service cold spray provider, core capabilities include: Cold Spray Process Development; Equipment Manufacturing, Integration & Leasing; On-Site Repair and Modification; Consumables; Training and Customer Support.

Cold Spray Solutions for Corrosion and Wear

Problem Statement:

Corrosion and Wear on High Dollar, Long Lead Time Parts and Components

Technology Solution Statement:

Cold spray technology is an ideal solution for addressing corrosion and wear in materials due to its unique solid-state deposition process, which offers several advantages over traditional methods. For corrosion, cold spray creates a dense coating with minimal porosity acting as an effective barrier against corrosive environments, it also reduces oxidation and various material options to choose from. For wear, cold spray's dense coatings contribute to superior wear resistance, preserved material properties and compressive residual stress which can enhance fatigue life and improve resistance to wear.Benefits Statement:

Repair and prevention of corrosion, reduces and repairs wear. Reduces down time and associated costs.