Technology Title

Infernoware Dissipate – Graphene Nanoplatelet Coating for Improved Thermal Management

Tech Focus Area

Surface Preparation and Corrosion Control

Abstract

Current heat management systems in defense applications often face challenges in efficiently dissipating excess heat, leading to overheating, reduced performance, and potential equipment failure. There is a need for an innovative solution that enhances thermal regulation, improves system efficiency, and ensures the longevity and reliability of heat-sensitive components.

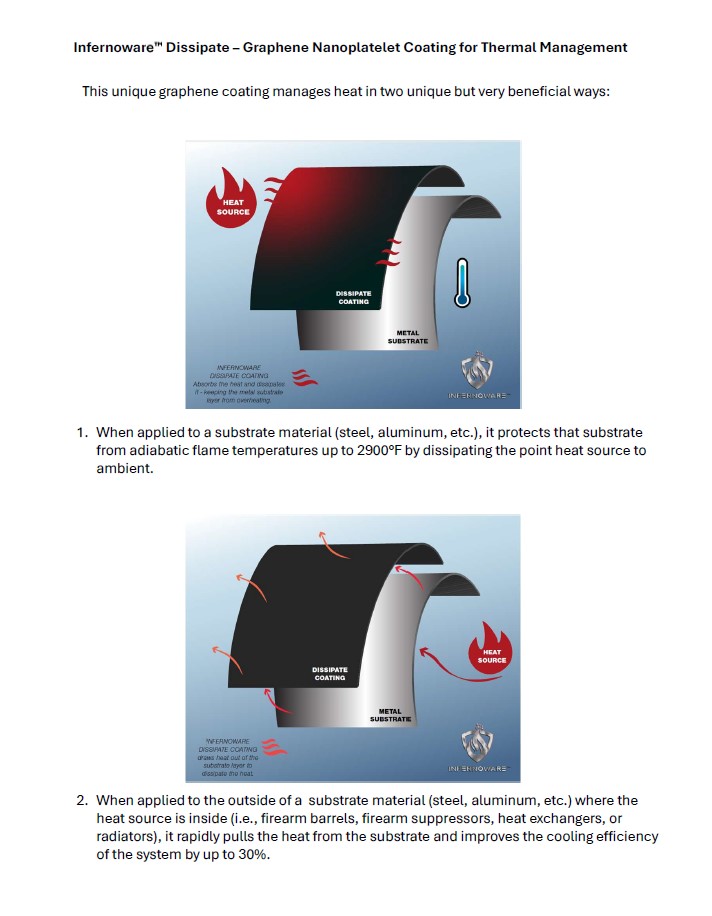

Infernoware™ Dissipate is a graphene nanoplatelet-based liquid coating that utilizes the unique properties of graphene to manage heat. The coating is a single-part, air-cure, spray coating that applies directly to a variety of substrate materials and improves thermal performance in two distinct ways:

Graphic

First, for components that are exposed to external heat or flame sources up to 2900°F, the Dissipate coating applied to the outside of the component absorbs that point source heat and transfers it elsewhere to ambient, protecting the substrate and everything behind it. This is useful in heat shielding applications where sensitive electrical components are located adjacent to heat-generating rockets or turbines, or to improve safety in applications where people may be exposed to heat or flame sources.

Second, for components that contain a heat source, such as firearm barrels, suppressors, and even heat exchangers and radiators, the Dissipate coating applied to the outside of the component acts as a sponge to quickly absorb the heat from the substrate and dissipate it to ambient. This greatly improves the thermal efficiency of the system. Applied to the cooling fins of a radiator, it can yield up to a 30% drop in the operating coolant temperature. On a titanium firearm suppressor under rapid-fire conditions, the coating can drop the outer temperature of the suppressor from 1000°F to 150°F in under 8 minutes, compared to over 30 minutes with an uncoated suppressor.

The coating is currently in production at lab scale and readily manufacturable. It has been field-validated in numerous industrial, transportation, and high-performance engine applications.