Technology Title

BEARS eCognition System for Health Monitoring of Metals, Concrete, and Tribology

Tech Focus Area

Surface Preparation and Corrosion Control

Abstract

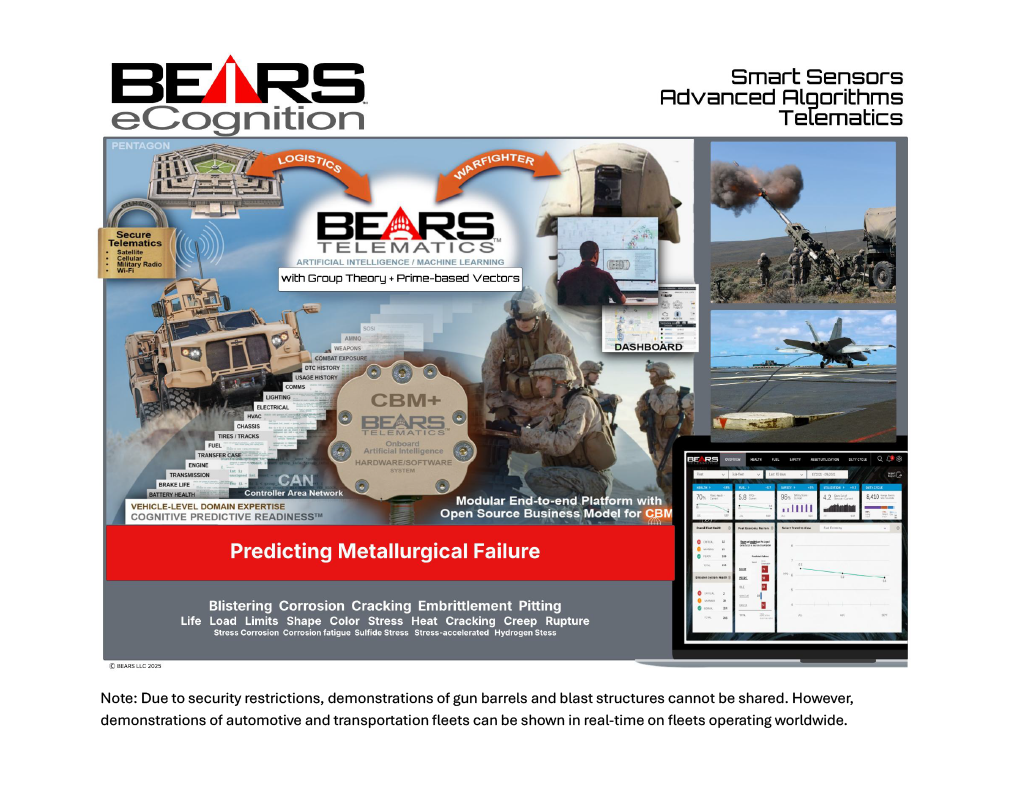

FOCUS AREA. The emphasis is on predictive analytics to address key metallurgical challenges in military applications, including bridging, gun barrels, vehicle structures, and aircraft carrier arresting gear. This encompasses predicting wear, fatigue, and failure in critical components like bearings and cables due to pitting and surface erosion.

PROBLEM STATEMENT. Anticipating material failure is crucial for predictive maintenance. Currently, sensors and algorithms have difficulties forecasting metallic failures. Military operations encounter risks if materials fail, jeopardizing personnel and equipment. The arresting system’s cables and pulleys transfer an aircraft’s energy to a large shock absorber, and any failure could disrupt air operations and affect our nation’s ability to project power. Predicting metallurgical failure is also essential for systems like gun barrels in long-range precision fires, impacting lethality and availability. Predictive maintenance of metallurgy is vital for our nation’s technical capabilities.

DESCRIPTION OF INNOVATIVE SOLUTION. This solution provides advancements in predictive maintenance: a robust smart sensor, a next-generation algorithm, and secure telematics. These innovations identify hidden failure patterns in military metallurgical applications. The algorithm employs group and number theory, spectral analysis, AI, and machine learning techniques. It detects fatigue in metal structures, bearings, and cables, facilitating condition-based maintenance, safety monitoring, and logistics optimization. Presently, this system is utilized worldwide for safety and regulatory compliance.

Graphic

BENEFITS TO THE DEPARTMENT OF DEFENSE. The system is versatile across different environments, prioritizing crucial maintenance and safety while providing accurate root cause analysis. It captures real-time data for predictive maintenance, minimizing risks and downtime. This solution accommodates mixed fleets, integrates with existing systems, and offers contextual analysis. Supported by extensive industry expertise, it enhances the government certification of safety-critical products. Predictive edge analytics deliver easily accessible insights for users and maintainers.

INNOVATIVE CHALLENGES. The three primary challenges include integrating advanced algorithms and software for metallurgical failure with the telematics system and unifying advanced mathematics, AI/ML, and predictive analytics.

TECHNICAL MATURITY AND DEMONSTRATION OF RESULTS. The core elements of the system are highly sophisticated. The sensor has accurately predicted metallurgical failure in structures subjected to high-energy blasts and large-caliber gun tubes. Globally, industrial and commercial clients have employed the telematics system for safety, vehicle development, and logistics, having logged over 900,000,000 miles in product development and validation. It features data bus connectivity, an AI-optimized computational platform, and secure cloud services.

Video Submission

https://www.bears-llc.com/what-we-do/enhanced-cognition/