Technology Title

Elinor Coatings ALUMA45 Chrome-Free Corrosion Protection

Tech Focus Area

Surface Preparation and Corrosion Control

Abstract

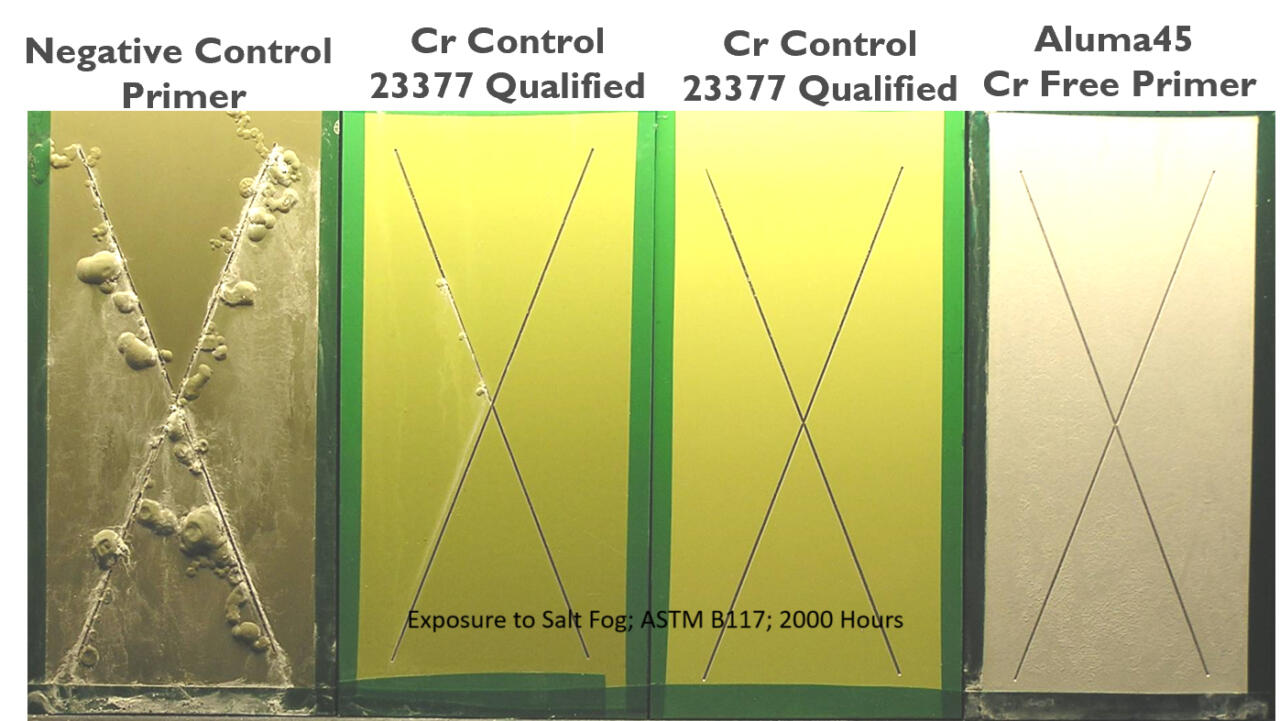

Elinor Coatings’ Aluma45 is a Chromate-free corrosion protection coating that provides repair timing flexibility and creates an opportunity to include embedded sensors for real-time monitoring to aid in predictive maintenance.

The DoD spends billions each year to mitigate the impact of corrosion on its assets, including aircraft, ground vehicles, and naval vessels. Current protective solutions for these critical assets involve using protective coatings to delay/eliminate the ingress of moisture/ corrosive pollutants from the environment to metal substrates. Chrome-based coatings provide protection against corrosion on aluminum substrates. However, the carcinogenic nature of chrome-based coatings (due to presence of hexavalent chromium) puts personnel at risk when exposed to these coatings during production, application, and removal. To eliminate the health and environmental risks from this pollutant, the DoD is looking for non-chrome, environmentally benign coatings that provide protection similar to chrome-based counterparts. Use of chromates also adds time and expense to the painting process by requiring an extra step in application and special care in the removal process during repair/refinish for collection, disposal and safety protocols dealing with the chromate residue.

Graphic

Aluma45 magnesium-rich, chromate-free primer protects Aluminum alloys through galvanic protection. It provides equivalent protection to chromate without harm or danger to the applicator or the environment. Unlike chromate treatments, Aluma45 does not rapidly oxidize on exposed surfaces and can act as a stand-alone coating eliminating the need to immediately apply an epoxy primer providing flexibility for applicators as the primer can be topcoated in as little as four hours or months later without further surface preparation. TRL 5; prototype in field trials.

Aluma45 provides three benefits to DOD painting operations: 1) safety – by eliminating chromate which is harmful to workers, the environment, and surrounding communities; 2) flexibility – by providing faster, more flexible turnaround thru elimination of the chromate step and time flexibility for topcoat application; 3) weight reduction – Aluma45 is applied in thinner coats than high build primers required by chromate treatments resulting in up to a 20% coating weight reduction benefiting fuel efficiency.

The next step in the innovation journey for Aluma45 technology will be incorporation of micro-sensors that can detect /monitor Aluminum Oxide formation, providing real-time monitoring to enable as-needed maintenance scheduling. By combining existing drone technology and AI-based corrosion-detection software, this coating will enable fast and accurate identification of corrosion before it can be seen thru visual inspection. This will allow maintenance teams to identify/monitor corrosion and prioritize maintenance efficiently, knowing which areas need to be prioritized because of deterioration rate or criticality.