Technology Title

Enhanced Expeditionary Maintenance Capabilities for Military Vehicles

Tech Focus Area

Expeditionary Repair of aircraft structural components

Abstract

Problem Statement:

Traditional maintenance, repair, and overhaul (MRO) processes for military vehicles, particularly the Joint Light Tactical Vehicle (JLTV), face challenges due to the increasing complexity of modern systems, high labor costs, and the need for faster turnaround times. As military vehicles become more advanced, maintenance time and manpower increase, leading to delays and reduced readiness. Manual maintenance methods are prone to errors, inefficiencies, and lack of real-time data.

Description of the Innovation Solution:

This project introduces an advanced maintenance platform that integrates predictive maintenance, augmented reality (AR), virtual reality (VR), and digital twin technology to enhance MRO operations for military vehicles. The solution provides maintenance personnel with 3D visualizations, interactive digital twins, and AI-powered predictive insights to enable faster, more efficient, and error-free maintenance. By transforming traditional technical orders into interactive, step-by-step 3D models, the platform allows real-time repairs and remote training. Predictive analytics forecast failures and maintenance needs, reducing downtime and preventing costly failures.

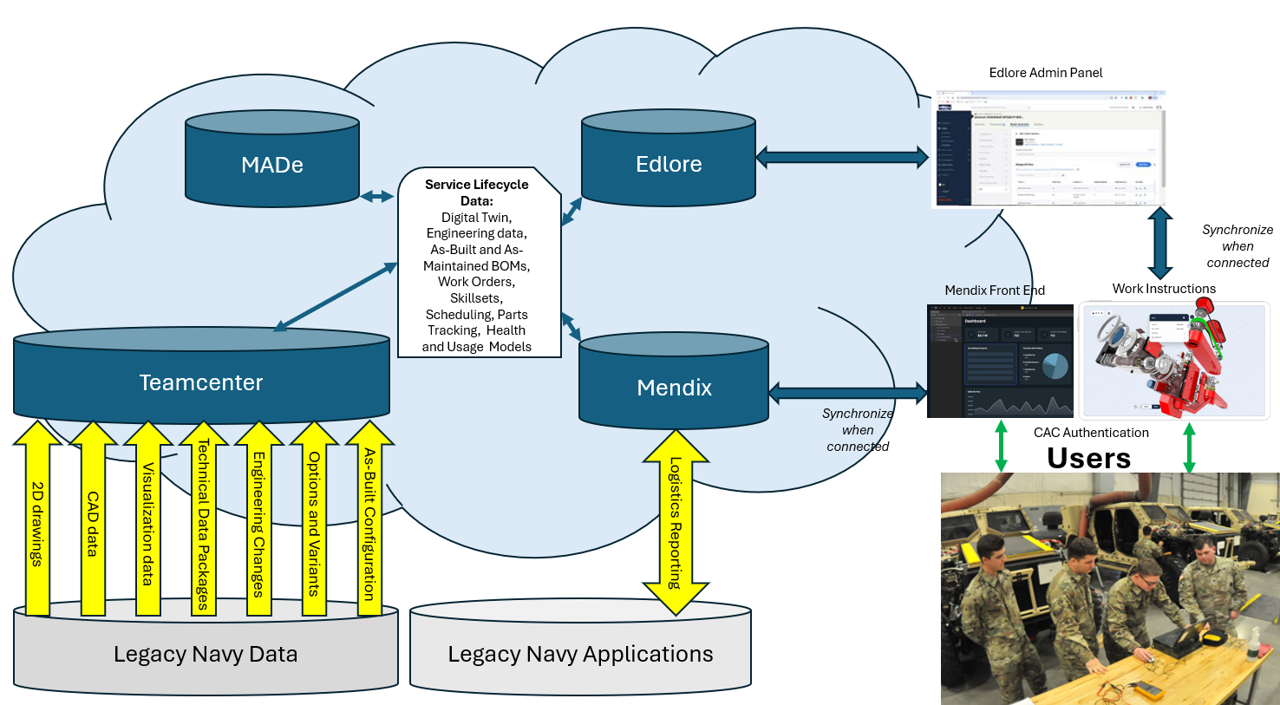

Graphic

The platform integrates data from Siemens Teamcenter (for lifecycle management), MADE (for predictive analytics), and Mendix (for a user-friendly interface), ensuring a seamless and comprehensive maintenance solution. The system is cloud-based, scalable, and adaptable for a range of military platforms, from ground vehicles to aircraft.

Benefits to the DOD:

This solution offers the Department of Defense (DoD) a transformative approach to expeditionary repair capabilities, making MRO operations more agile, efficient, and cost-effective. By reducing manual labor, eliminating errors, and shortening repair times, the platform improves readiness and keeps mission-critical systems operational. The predictive maintenance feature decreases unplanned downtime, improving material compatibility and structural integrity. Additionally, AR/VR enables real-time repairs and efficient remote support, essential for field conditions.

Innovation Challenges:

Integrating advanced technologies like AR/VR and predictive maintenance into existing military workflows poses challenges. Overcoming resistance to change and ensuring adaptability across diverse military environments are key hurdles. Moreover, ensuring the platform’s environmental resilience and energy efficiency in harsh, mobile settings requires rigorous testing and optimization.

Technical Maturity/Demonstration Results:

The platform has undergone successful demonstrations in military environments, including testing with the U.S. Navy and the U.S. Air Force. The technology readiness level (TRL) of the solution ranges from 6 to 8, confirming its maturity and deploy ability. The integration of predictive analytics, AR/VR, and digital twins.