Technology Title

Infernoware Dissipate – Graphene Nanoplatelet Coating for Improved Thermal Management

Tech Focus Area

Surface Preparation and Corrosion Control

Abstract

Background:

Highlights of GAO-23-105481(4/2023) indicates that the Navy experienced more than $4 billion in estimated damages caused by fires on ships undergoing maintenance from May 2008 – Dec 2022. The high risk of fire included “hot-work activities” that create sparks.

Problem:

Traditional grinding operations present one of the highest risks associated with naval ship construction and overhaul. Mandatory labor-intensive, pre-inspections and continuous space management procedures are necessary to prevent shipboard fires. A prerequisite to any grinding operation includes fire watch, removal and cleaning of the spark affected area, and gas free preparation of each space and adjacent “back side” space. As a result, grinding evolutions are generally some of the costliest operations.

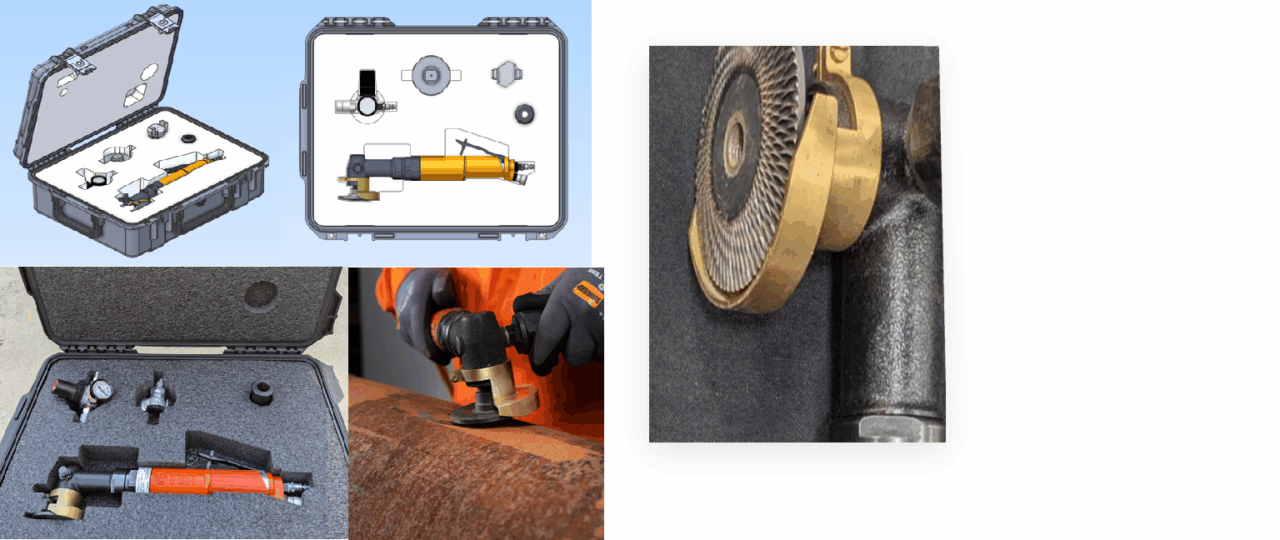

Graphic

Cold Milling as a Solution:

Originally called “sparkless grinder” because of its ability to perform grinding applications, but without the introduction of sparks, removing the need for hot work requirements. The tool has since been rebranded as “cold milling” to get away from the word “grinder” which indicates hot work in its name.

Works like grinders

- Wheels cannot fit on standard high RPM grinders (governed @ 1000 RPM, prevents misuse)

- Fluted wheel design – Controls generated waste (no build up)

- Harder than diamond (Proprietary Carbide Composite Wheel)

- Contains no beryllium in composition (No chronic exposure to beryllium to cause CBD)

The Benefits of this Technology:

General Benefits:

- Low Noise (<85 dBA)

- Light weight ergonomic (<7 lbs.)

- Can be used on various substrates

- Controlled removal rate (slower speeds = more controlled)

- Achieves an SSPC-SP-11, SPF-11 profile finish (40-75 microns)

No Hot Work:

- Completely removes the potential for ignition/fire

- Low Heat (95-115º F)

- No Sparks

- No Fire Watch Needed

- No Static Produced

Multiple Use Cases:

- Surface Preparation (SPF-11 Profile Finish, 40-75 microns)

- Adhesive studs

- Painting

- Preservation

- Anywhere a traditional grinder can be used