Technology Title

Interoperability Platform for Monitoring Legacy Equipment

Tech Focus Area

CBM+

Abstract

Upgrades in monitoring have not kept pace with the commercial sector’s rapid changes and new technologies, particularly on older infrastructure whose lifespans reach 30+ years. Deployed systems have limited ability to provide affirmative readiness assurances due to siloed and disconnected infrastructure hence creating significant interoperability hurdles and resulting in incomplete and inaccessible data. The lack of interoperability across subsystems, analog and digital sensors, and modern and legacy machinery, restricts sensor fusion resulting in siloed information limiting ability to make informed decisions especially during critical periods of operations.

SRT Labs overcomes this problem by providing a hardware-agnostic, interoperability ecosystem that connects analog and digital subsystems, in addition to providing condition-based maintenance, real-time asset tracking, and infrastructure monitoring. Consolidated base-wide monitoring is most useful when there are both complex systems and a labor shortage. Commands such as NAVSEA, MDMC, and NAVFAC have the added difficulty of assets distributed across miles on bases and across multiple bases, so monitoring of these complex systems (currently with many manual steps) stresses resources, and most importantly cannot provide the complete picture of the current state of all assets. These deployments focus on cost avoidance and minimizing the risk of failure of critical infrastructure systems and machinery.

This solution provides diagnostic and prognostic assessments and improves machinery health and operational efficiency by providing early detection of degraded system performance, reducing the need for human input, expensive delays during maintenance work, safety concerns caused by critical failures, and ensuring optimal conditions for maximum system performance and readiness. ROI has been demonstrated in the identification of machine performance issues that would have caused unplanned downtime in several active deployments.

CAPABILITIES. Operational Deployments (TRL9) at PSNS

- Motor health vibration monitoring for pumpwells & critical machinery

- Gate & valve position monitoring

- Motor & pump state monitoring

- Water intrusion monitoring

- Runtime monitoring by both machine state & current draw

- Filter health monitoring for portable Dust Collectors

- Incoming power monitoring across machines

- Wastewater contamination & flow monitoring

- Paint & sand blasting booth monitoring (MDMC)

CURRENT PSNS DEPLOYMENT

- 300+ sensors (machine shop, 3 pumpwells, 7 caissons, 1 drydock, 2 lift stations, 30 dust collectors)

- LoRaWAN network to support up to 10,000 devices

- HERO/HERF approval for 12 device types

- Containerized software for IL2/IL4/IL5

- Alerts, compliance reports, & text/email notifications

This software has broad DOD applicability—deployed with USMC and working with USAF—addressing the needs to unify the “data plumbing” for maintenance systems that span decades.

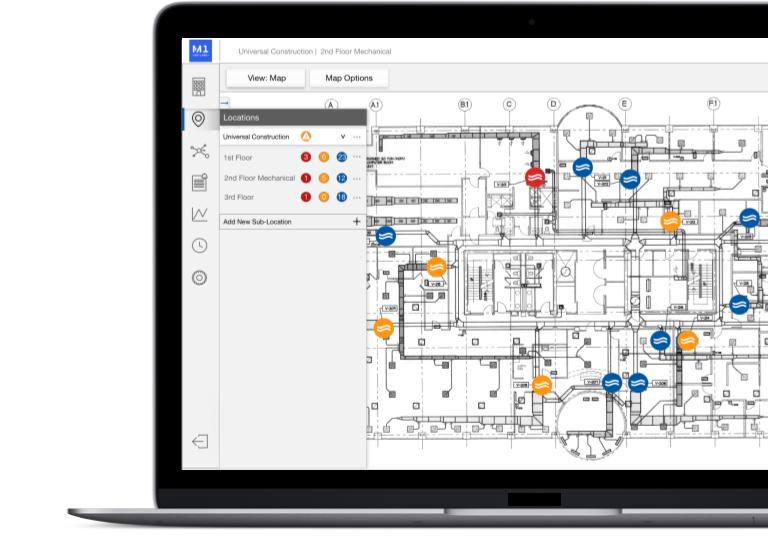

Graphic