Technology Title

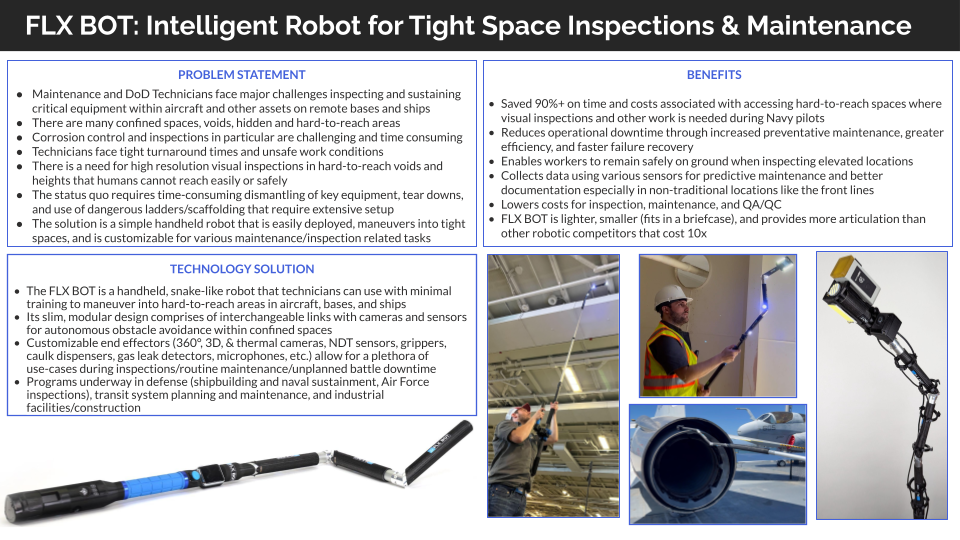

FLX BOT: Intelligent Robot for Tight Space Inspections & Maintenance

Tech Focus Area

Robotics and Automation

Abstract

Surface preparation & corrosion control are critical processes to ensure structural integrity and longevity of aircraft, ships and DoD assets. Challenges include:

- Labor-intensive/time-consuming manual processes

- Inconsistency/lack of precision in inspections/maintenance

- Inability to gain access to tight spaces on ships and aircraft, or insufficient lighting

- Reliance on subjective visual inspections

- Safety risks for personnel in confined spaces, on ladders/scaffolding

FLX BOT, a handheld, 1” diameter, articulating robot is designed to address these challenges and advance the efficiency in surface preparation & corrosion control.

- Integration of Ultrasonic NDT end effector allows for enhanced detection/monitoring of corrosion, enabling predictive maintenance and lifecycle management

- 360° articulation allows access to hard-to-reach areas critical for maintenance, reducing the need for time-consuming disassembly

- Field demos in the DoD have shown reductions in inspection times (90+% time savings), demonstrating improved efficiency vs. current manual maintenance practices

- Remote operation reduces risks associated with hazards, confined spaces avoiding ladders/scaffolding

Graphic

The FLX BOT (TRL 6) successfully demonstrated in relevant environments:

- Vigor Shipyard (Seattle)

- SALVEX Battlefield Damage Assessment (BDA) Exercise (Hawaii)

- Atlantic Thunder BDA Exercise (Philadelphia)

- MTA Transit Authority (NYC)

- Air Force – Aircraft Wing Fuel Tank Inspections

Results from pilots:

- Significant reductions in inspection times (e.g., 90+% time savings in DoD exhaust duct inspections)

- Positive user feedback and rapid user adoption by DoD techs

- Successful development and testing of a custom Ultrasonic NDT end effector for corrosion detection

Benefits to the DOD:

- By automating and streamlining inspections/maintenance, the FLX BOT reduces cycle times, manpower requirements, and costs associated with corrosion control

- Faster and more efficient maintenance translates to improved operational readiness of DoD assets

- Reduces labor costs, decreases downtime, and prevents costly failures

- Remote inspections minimize risks & hazards to personnel

- The FLX BOT’s capabilities are readily applicable to any service branches of the DoD for a wide range of inspection/maintenance tasks in various environments

Innovation Challenges:

- Further development of AI-driven analytics for enhanced predictive maintenance

- Expanding the library of modular end effectors for diverse applications

- Ensuring seamless integration with existing DoD systems and data infrastructure

Next Steps:

- Scaling up FLX BOT procurement and deployment across DoD facilities

- Formalizing training programs and SOPs for widespread adoption

- Continued R&D to enhance capabilities, including AI-driven analytics and real-time corrosion monitoring

- Establishing a centralized support and maintenance system for long-term reliability

- Secure long-term funding and support for large scale deployment