Technology Title

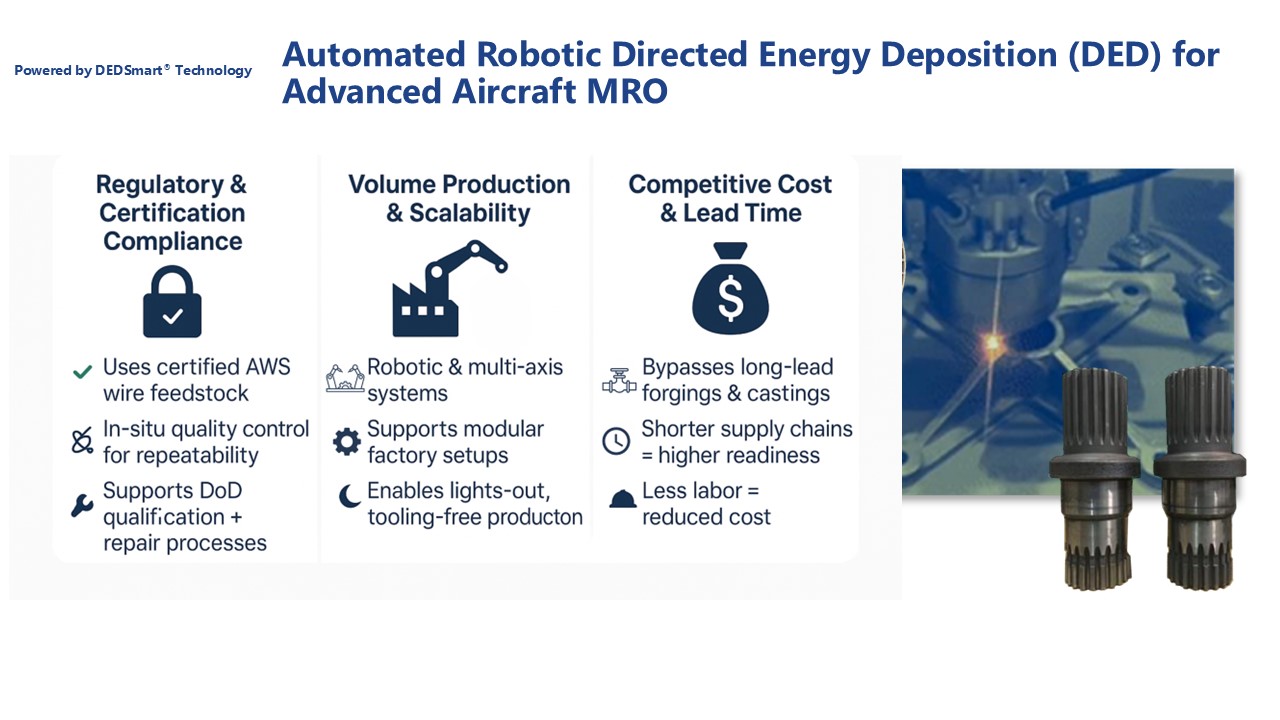

Automated Robotic Directed Energy Deposition (DED) for Advanced Aircraft MRO

Tech Focus Area

Robotics and Automation

Abstract

Focus Area:

Robotics and automation for Maintenance, Repair, and Overhaul (MRO) of aircraft, engines, and aeronautical components.

Problem Statement:

Long lead times, limited manufacturing sources, and complex geometries make conventional maintenance and repair methods increasingly unsustainable. Manual inspection and repair processes are time-consuming, variable, and difficult to scale. There is a critical need for precision, automation, and adaptability in MRO operations to enhance readiness, reduce costs, and extend the lifecycle of mission-critical assets.

Description of the Innovative Solution:

FormAlloy’s robotic Directed Energy Deposition (DED) technology meets this challenge by integrating additive manufacturing, automated inspection, and intelligent toolpath generation into a single, autonomous MRO cell. Using wire and/or powder feedstock, our DED process repairs and rebuilds metallic components layer-by-layer with high precision and material integrity. Multi-axis robotic systems allow flexible positioning for complex geometries found in aircraft, engines, and other aeronautical components. The solution incorporates in-situ sensors and real-time monitoring to ensure repeatability, traceability, and minimal human intervention.

Graphic

Benefits to the DoD:

FormAlloy’s technology drastically reduces turnaround time by eliminating the need for traditional casting or forging, enabling on-demand, point-of-need part restoration. This accelerates readiness, shortens supply chains, and reduces labor dependency. High-precision robotics minimize rework and maximize part quality. Our process aligns with DoD qualification standards by using certified feedstocks and integrated quality control. The system’s modular, scalable design supports deployment across depots or forward-operating environments.

Innovation Challenges:

Key challenges include integration with legacy MRO systems and technical data packages, as well as qualification within existing digital twin and sustainment ecosystems. Regulatory compliance—particularly around airworthiness, NDE, and material traceability—remains a barrier to widespread adoption.

Technical Maturity / Demonstration Results:

FormAlloy’s DED system is production-ready and has been successfully demonstrated in aerospace and defense environments. Proven materials include titanium, Inconel, aluminum and steel alloys. Notably, FormAlloy has repaired a landing gear component for Fleet Readiness Center Southwest (FRCSW) and supported NAVSEA with valve bodies. The system operates autonomously in a robotic cell configuration and has been integrated with multi-axis robotics for parts exceeding one meter in X, Y, and Z dimensions.

Next Steps for Development:

FormAlloy will collaborate with the DoD to further qualify robotic DED processes on representative components. Planned next steps include integration into operational MRO workflows, testing, and support for accelerated qualification through sensor-driven and data-backed analysis.