Technology Title

Scalable, Affordable RFID Corrosion Sensors

Tech Focus Area

Surface Preparation and Corrosion Control

Abstract

Problem

Corrosion’s global cost is $2.5 trillion. The DoD spends $20 billion annually, 20% of all maintenance dollars. Corrosion also creates operational downtime. In 2021, corrosion cost the Navy $7 billion and 11 million downtime hours. Yet, we still don’t have great ways to manage corrosion. Monitoring is underutilized due to the expense and difficulty of data retrieval. Lack of real data in field conditions leads to inaccurate models, yielding excessive maintenance or unexpected system failures.

Solution

Scalable, affordable RFID Corrosion Sensors.

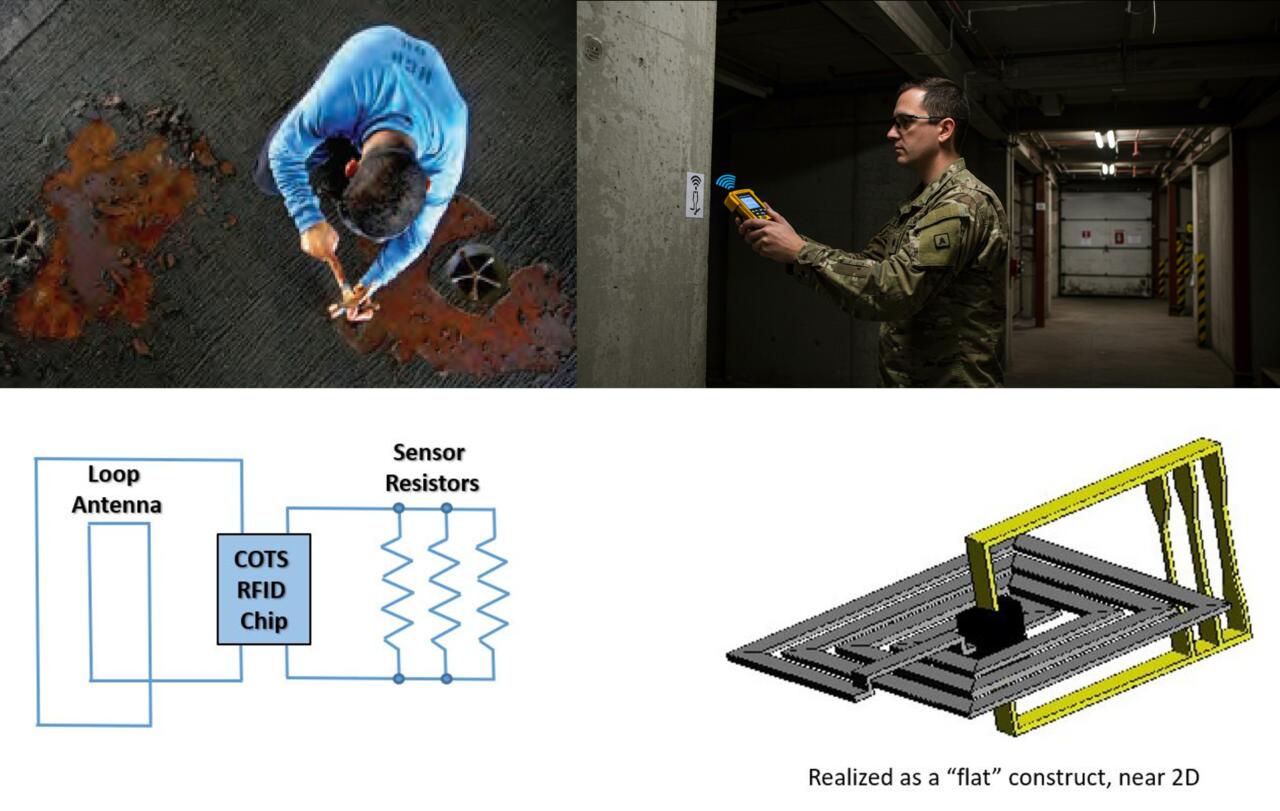

The sensors are RFID tags that monitor atmospheric corrosion, providing actionable insights to protect valuable systems from corrosion. The idea was patented in a Naval Lab, where lack of good monitoring led the radar Chief Engineer to a better solution.

The sensors are small and affordable enough to stick anywhere and allow data to be easily gathered. Periodic RFID scans record an atmospheric corrosion trend, which is correlated to corrosion on nearby equipment. Scans can be easily added to existing inspections.

The sensors expose 3 copper wires of increasing diameter and measure resistance across them. As the wires corrode and fail, resistance increases, matching the rate of corrosion. Because they are so simple, the scale manufactured cost will be less than $5. The first version is passive, for ease of DoD deployment, but later versions will be active for continuous data gathering and transmission.

Graphic

While there are other products that measure corrosion, these are unique in ease of use and affordability. Currently, our ability to create AI predictive models for corrosion is severely limited by small data sets. Having a simple, affordable sensor will enable gathering large data sets and leveraging the power of AI to revolutionize how we manage corrosion.

DoD Benefits

Corrosion is a challenge across the DoD. Better ability to monitor and AI predictive models will lead to optimized maintenance costs and reduced downtime and failure risk. Example high benefit applications include monitoring equipment in storage, refining environmental site severity classifications and the resultant equipment maintenance schedules, and monitoring hard to see places that tend to corrode, such as pipes under insulation.

Technical Maturity

This technology is TRL 3. It has been demonstrated in the Naval Lab, effectively producing a step function measurement of atmospheric corrosion as each wire corrodes.

Challenges

We are now prototyping the sensors as RFID stickers to test more rigorously in the lab and field. Challenges include optimizing the sensors to measure data robustly in the field, due to greater variability from changing weather and human actions (ex: equipment washes). We are working with a contract manufacturer to produce prototypes and are implementing a CRADA with the Naval Lab for the next stages of testing. We have identified multiple DoD organizations interested in piloting the sensors.

Video Submission

https://drive.google.com/file/d/1lS_FLZCXQDkNtuodhxTqzU4ud4li2eUX/view?usp=sharing