Technology Title

Null Zone Magnetic Sensor (NZMS) for Advanced Debris Detection in Fluid Systems

Tech Focus Area

Reliability Improvement

Abstract

Fluid systems in ground vehicles, support equipment, naval vessels, and aircraft used for Defense Operations are currently unmonitored and early warning signs of failure are missed resulting in unplanned downtime, safety risks, and costly repairs. In nearly all cases, small amounts of ferrous debris are the earliest and most reliable indicators that pumps, bearings, or gearboxes are beginning to degrade. Existing debris sensor solutions do not meet the needs of the Department of Defense and have therefore not been widely adopted. As a result, maintenance personnel are often forced to react to failures only after they become imminent, leading to unplanned downtime, higher sustainment costs, and reduced mission readiness.

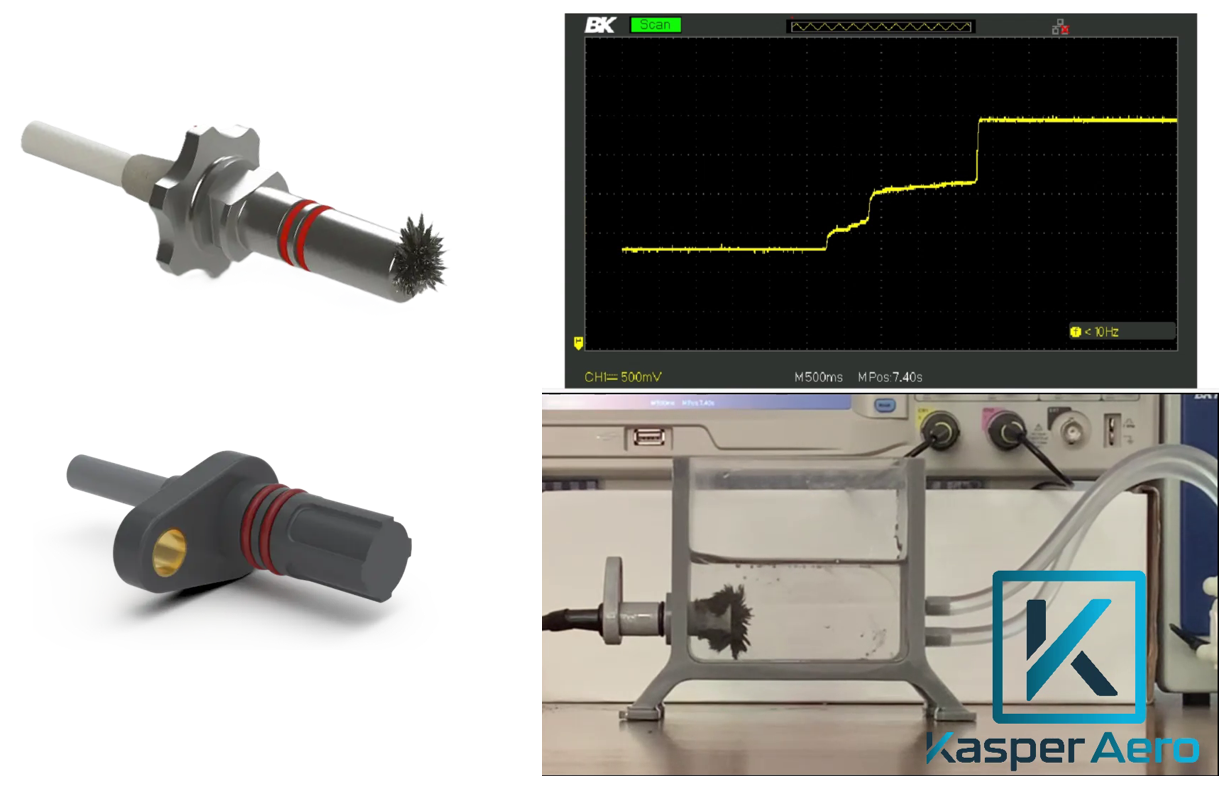

KasperAero developed the patent-pending Null Zone Magnetic Sensor (NZMS), an active ferrous debris detection technology that addresses the shortcomings of legacy sensors. Rather than relying on capacitive, ultrasonic, or spectroscopic methods the NZMS operates on a new sensing principle using magnetic field distortions from ferrous debris.

The NZMS has four primary components: a housing, printed circuit board, permanent magnet, and a magnetic field sensor. The sensor’s simplicity enables cost effective and compact designs while providing superior sensitivity. This compactness and cost effectiveness makes the NZMS suitable for both retrofit applications and integration into new systems.

By identifying critical component wear at the earliest stage, the NZMS makes predictive maintenance possible by providing real-time, quantitative feedback about the health of critical fluid systems. For the Department of Defense, this capability means:

- More efficient use of maintenance resources

- Catastrophic failure warnings for DoD Vehicles

- Improved safety for personnel and equipment

The main challenges in bringing the NZMS to market are environmental validation, scaling for production, and integration with existing maintenance frameworks. Integration will require connecting the NZMS output to existing onboard computers and DoD predictive maintenance dashboards and data systems. The unique operating principle of the NZMS creates challenges in the sensor’s assembly that must be resolved to achieve production-scale output.

The NZMS has been prototyped and is at TRL 4. Initial bench testing has shown a high sensitivity to as little as 0.015 grams of 10-micron ferrous debris and extreme thermal stability. Next steps involve environmental testing per DO-160G and MIL-STD-810 standards. Testing must be performed to characterize the sensor’s output in relationship to the total mass of debris collected, ensuring actionable data for end users.

The Null Zone Magnetic Sensor addresses a critical gap in fluid system health monitoring. With its combination of sensitivity, durability, and low cost, it offers the Department of Defense a practical pathway to reduce maintenance costs, improve safety, and increase readiness across its vehicle fleets.

Graphic