Technology Title

Analatom: A Multispectral AI-enabled Inspection System for Warfighter Defect Detection

Tech Focus Area

Surface Preparation and Corrosion Control

Abstract

Aircraft maintenance, repair, and manufacturing requires precise, efficient, and repeatable inspection methods to ensure structural integrity and operational safety. While drone and robotic technologies have increased the availability and quality of inspection data, defect detection remains largely manual. Traditional non-destructive inspections are labor-intensive, costly, and prone to human error. Analatom’s Automated Inspection with Deep Learning (AIDL) software combines machine vision and artificial intelligence within a human-in-the-loop workflow to deliver accurate and reliable defect detection capabilities to AF MRO depots. It’s deep learning models are fine-tuned to each inspection domain and capable of autonomously detecting and localizing defects in aerospace components, including cracks, corrosion and other structural anomalies. Difficult and ambiguous samples, determined using a built-in confidence metric, are passed to the technician for manual decisioning. To facilitate QA and review, the software outputs bounding boxes and heatmaps of the detected defects so that technicians can quickly understand the machine logic and identify any areas for further fine-tuning. The combination of machine and human decisioning increases inspection efficiency, reducing the time and labor needed to complete the inspection.

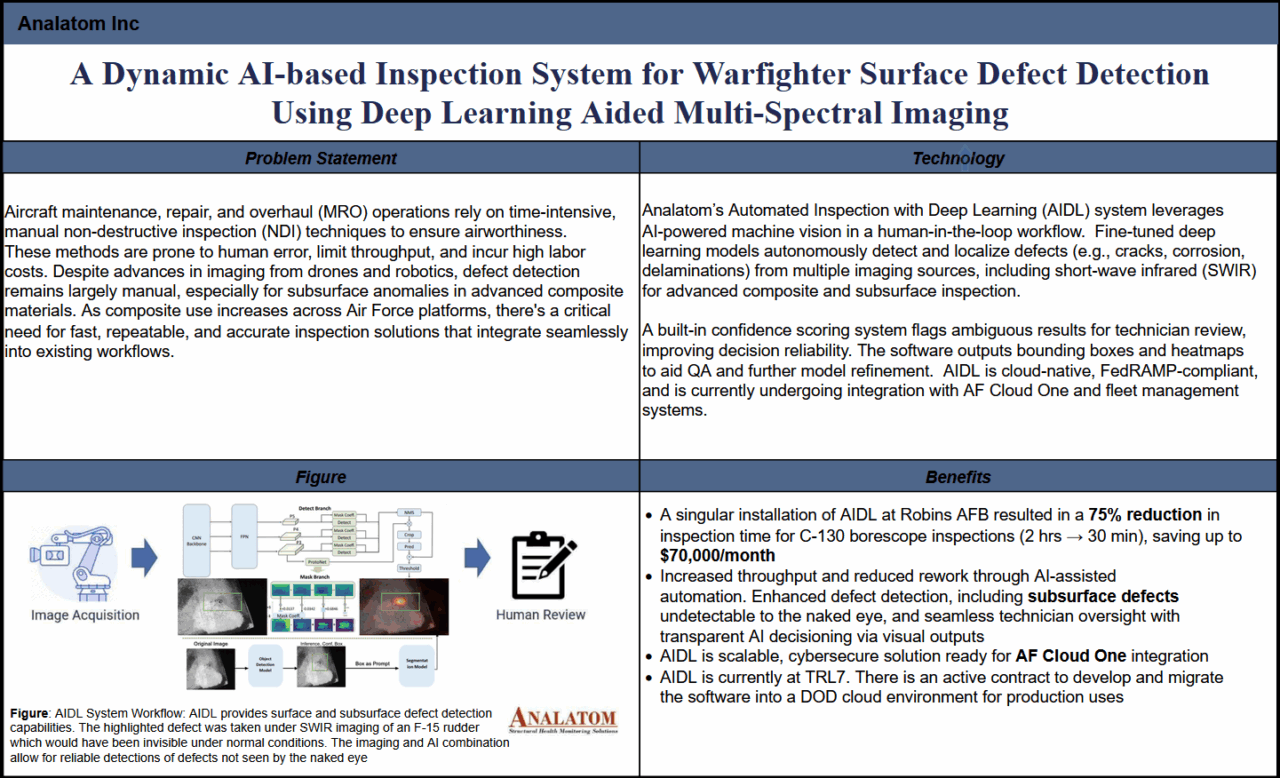

Graphic

Additionally, AIDL is compatible with a variety of imaging sources and domains, including short-wave infrared (SWIR) which is used to detect subsurface defects in aerospace composites. SWIR imaging can penetrate beneath the surface of select composite materials, allowing for the detection of voids and delaminations invisible to the human eye. As the use of composite materials increase, subsurface defect detection capabilities become an increasingly critical capability for the AF. Due to its cloud architecture, AIDL is highly scalable and offers FedRAMP-compliant cybersecurity protections for data. Connections to other fleet management systems are configurable. Efforts to migrate into the AF Cloud One environment are in flight, offering additional flexibility and ease of integration for future AF customers. The primary benefits of the AIDL solution include improvements to inspection accuracy and reliability as well as reductions in maintenance costs and downtimes due to automation. AIDL has been adapted and deployed for the inspections of C-130 propeller blades at Robins AFB. For the C-130 borescope inspection, the AIDL solution demonstrated a 75% reduction in inspection time from 2 hours per blade to 30 minutes due the decrease in manual decisioning of borescope images. This could save the facility up to $70,000 per month in labor and overhead costs while increasing the number of blades processed per day. The tool was also demoed for the inspection of a boron-composite skin on F-18 rudder blades. The SWIR imaging and deep learning models were able to detect defects that were previously only found via x-ray and ultrasonic machines.