Technology Title

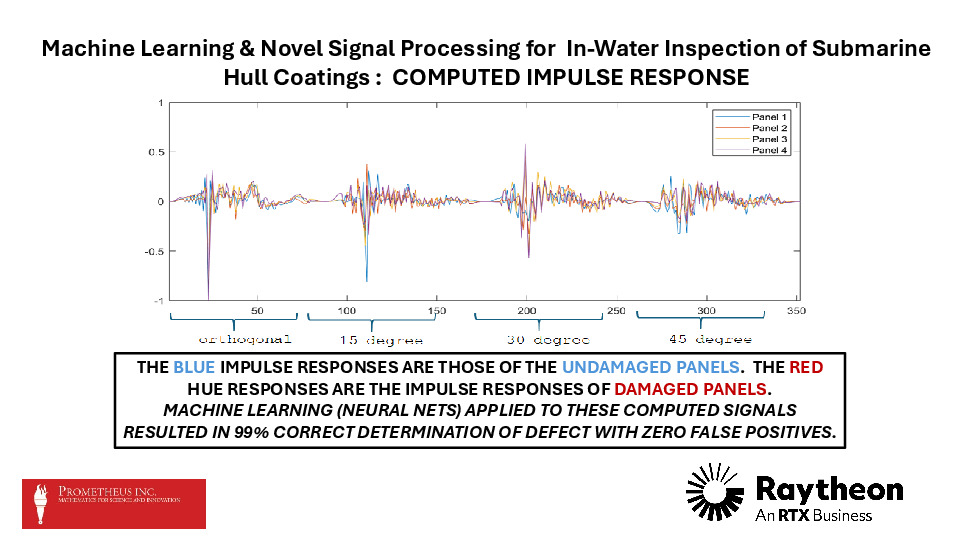

Machine Learning & Novel Signal Processing for In-Water Inspection of Submarine Hull Coatings

Tech Focus Area

Enhanced Inspection

Abstract

Hull coatings and their maintenance are critical for the submarine force. Here we describe Hardhead, a means to use novel signal processing and machine learning to detect and classify under-coating lamination defects caused by adhesive failure or surface corrosion. The method relies on collecting mid-frequency sonar signals at close range and does not require any contact with the coating. This will reduce the cost and duration of submarine hull coating inspection, a significant factor in overall submarine availability to the fleet. In turn, this will offer important cost savings and risk mitigation for the Navy.

We have adapted methods from previous work classifying elastic material properties from sonar returns in real time to enable the capability to perform in-water submarine hull coating delamination detection. Previously, our team’s work for NASA Langley characterized aircraft composites using a data-driven

method based on wavenumber images (spatial FFT), and the MIRK (Material Identification Reflectivity Kernel) technology. In parallel, research at NUWC by Dr. A. Hull revealed that the physics of delaminated coatings underwater yielded a scattering pattern strongly differentiated from fully-bonded coatings, motivating our research into acoustic methods for detection of delamination. Importantly, and distinctly from many NDE methods, Hardhead uses signals scattered from the coating surface; we do not need to ‘penetrate’ the coating with the sonar. Our method uses a combination of signal processing and physical feature generation and a variety of AIML algorithms to classify coating panels as defective or fully bonded.

We have validated the Hardhead classifier using two data sets: one set of panels manufactured by NAVSEA and tested at NUWC’s ATF facility, and another manufactured by Collins Goodrich and tested at NUWC’s Dodge Pond. On each panel, sites with varying sizes (zero to large) of delamination were created.

In the test tank, waveforms and angles of incidence were varied to generate the test data sets of several thousand independent measurements. Our analysis showed that the delaminated areas affected the scattered acoustic signal, and that this effect is reliably detected and classified, even in the presence of bio-fouling, both under the coating and under the epoxy paint layer. We achieved >99% accuracy in discriminating pristine panels from those where delamination was present.

We are conducting initial studies to integrate Hardhead onto ROV and UUV inspection platforms. This engineering work, validation with in-service Navy materials, and integration with submarine maintenance workflows, will be part of future work.

Graphic