Technology Title

REACH: Robotic Element for Autonomous Cargo Handling

Tech Focus Area

Autonomous Logistics

Abstract

Baggage handling remains almost entirely manual across all DoW branches. At passenger terminals and aerial ports, logistics personnel lift rucksacks, duffels, and deployment bags that can weigh up to 110 lbs. A single flight can require more than 7,000 lbs of baggage to be moved by hand. This slows throughput, increases musculoskeletal injury rates, and diverts manpower from mission-critical roles. Lost or delayed baggage further undermines readiness and operational timelines.

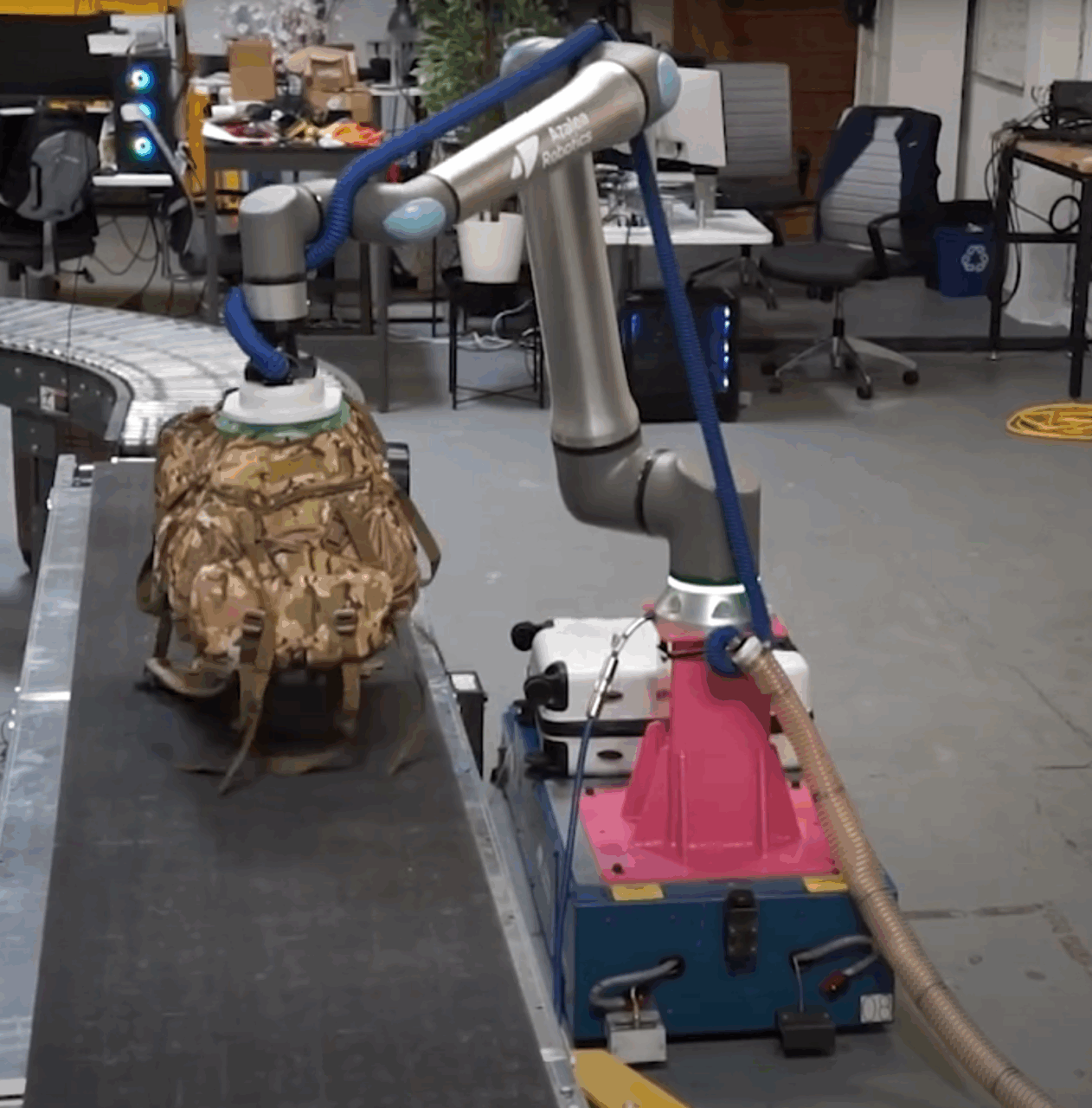

The Robotic Element for Autonomous Cargo Handling (REACH) is a mobile, wheeled robotic platform that autonomously lifts, transfers, and stages baggage. The platform consists of UR 20 certified components for autonomous robotic safety standards. A six-axis arm mounted on a four-wheel base operates effectively in bag rooms and ramps. Its dual-mode gripper applies suction for soft bags and mechanical force for rigid/irregular loads. Stereo and depth cameras, time-of-flight sensors, and force feedback create a 3D map of the work zone, select grip points, and confirm secure lifts. All perception and control run locally for real-time adaptation without preset routines. Each lift generates a 3D scan and time-stamped record, producing a digital trail that integrates with current tracking systems.

REACH reduces injury risk, conserves manpower, and traces throughput to directly improve troop movement across the DoW. Repetitive lifting exposes handlers to back, shoulder, and knee injuries that limit availability and increase medical costs. REACH lowers injury risk and keeps more personnel fit for duty. It also reduces the size of teams needed for each passenger movement to more efficiently use manpower. One operator can oversee several robots at once, which frees significant hours for training, aircraft preparation, and deployment planning. REACH produces a 3D scan and time-stamped record for every lift to trace throughput. This creates a verifiable digital trail that shows how much baggage has moved, where it is staged, and how long each step took. The result is greater accountability, fewer lost items, and stronger confidence in deployment timelines.

Innovation challenges focus on grip reliability with strap-laden or irregular bags, sensor accuracy in low-light or cluttered environments, and integration with legacy logistics software. Mitigation includes reinforcement learning tuned to military baggage, redundant safety systems independent of AI control loops, and modular components for future upgrades.

REACH has reached TRL 6. It has demonstrated consistent success rates lifting and transferring loads up in controlled pilots. Its hardware components are commercially sourced and its software is proprietary.

Graphic