Technology Title

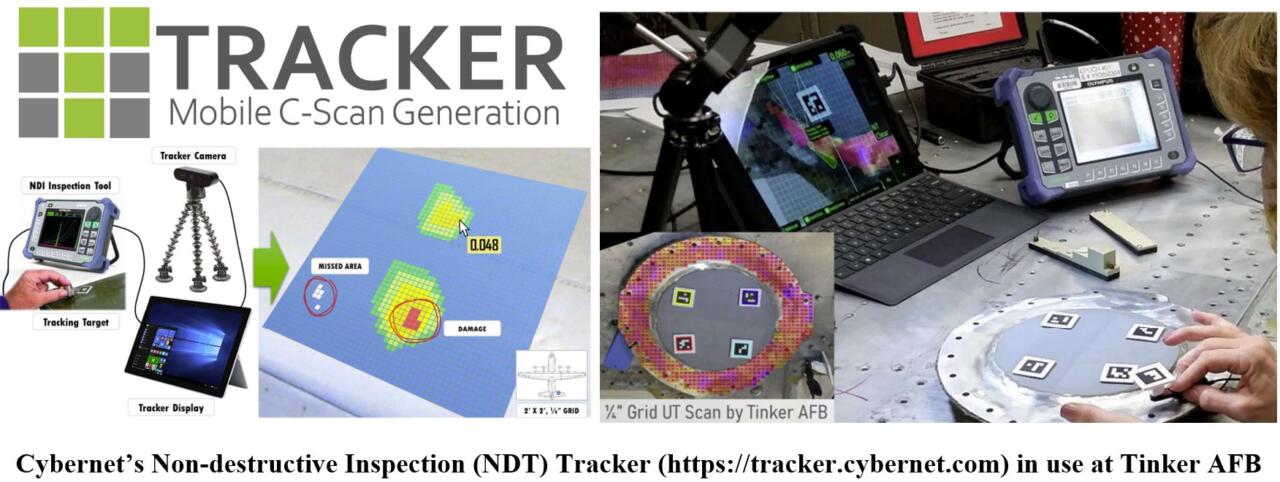

NDT Tracker for Mobile C-Scan Generation

Tech Focus Area

Expeditionary Repair of aircraft structural components

Abstract:

Problem Statement: Ultrasonic (UT) grid inspections, widely used by aircraft Maintenance, Repair, and Overhaul (MRO) facilities to map corrosion and verify remaining thickness, are slow, tedious, and labor-intensive. Typically, 0.5″ or 0.25″ grids are hand-drawn on surfaces or paper, requiring two inspectors to coordinate readings and record them manually. The resulting numerical grid lacks visual context, relying on imprecise drawings and descriptions to locate inspection areas. Miscommunication between inspectors and engineers often leads to re-inspections, causing unscheduled maintenance costs and delays.

Solution: The U.S. Air Force and Cybernet Systems Corporation developed the NDT Tracker, a mobile, camera-based tool that reduces UT grid inspection labor from two inspectors to one, cutting labor in half. The Tracker eliminates hand-drawn grids and manual recording, using patent-pending AutoClick Combo-Filtering to auto-select accurate thickness readings, reducing average inspection time from 20 to 2 seconds per cell—a 10x efficiency gain. Color-mapped C-Scan reports over inspection area imagery eliminate re-inspections due to miscommunication. The shortened inspection phase accelerates turnaround time and boosts maintenance throughput (exact figures confidential). The Tracker now operates from 0.5-5ft range with a 4ft x 4ft inspection area extendable via leapfrogging.

Graphic

Benefits to the DoD: The Tracker enhances “Readiness to Deploy and Fight” across the DAF and DoD by:

- Accelerating NDT inspections, improving aircraft maintenance efficiency and availability.

- Enhancing training speed and inspection quality with real-time coverage mapping, increasing probability of inspection (POI) and enabling accurate damage mapping.

- Improving communication with color-mapped C-Scan deliverables and digital PDF/CSV outputs, preventing delays from manual drawing misinterpretations.

Innovation Challenges Overcome:

- Portability, Deployability, and Ease of Use: Developed a lightweight, mobile solution (28 lbs, 5-10 min setup) with an intuitive interface for high school graduate-level personnel, meeting Air Force requirements.

- Automation and Augmentation Balance: Optimized speed, accuracy, and feedback to maintain inspector confidence.

- Adoption: Secured inspector buy-in, pivoted from 3D localization technology originally developed for NASA to the Tracker solution, and transitioned from federal funding to commercialization.

Technical Maturity/Demonstration Results: The Tracker is in active use at Tinker AFB, Robins AFB, and by commercial MROs like Delta TechOps, ST Engineering, and Aeroman. Aircraft manufacturers (Boeing, Airbus, Gulfstream) are pursuing adoption. The Tracker won the 2024 SAE/A4A International Innovation Award and the 2024 ASNT Cool New Ideas Award by popular vote. This revolutionary tool transforms UT gridding for the Air Force and is poised to impact NDT inspections across the DoD.