Technology Title

Multi-Layer System Lagging Product

Tech Focus Area

Coatings/Corrosion Prevention

Abstract

A common problem associated with traditional chill water pipe lagging is corrosion under insulation, or CUI. When chill water runs through piping on ships condensation builds up and drips on pipes as well as fittings and other components in the vicinity, causing costly corrosion to equipment requiring further work and repairs.

Solarcore’s proprietary lagging alternative offers an easy to install solution which is fast and effective. The low-profile aerogel material eliminates the thermal transfer of energy with only a few millimeters of thickness attached directly to surface of the piping, elevating the surface temperature above the dew point away from the pipe eliminating condensation formation in critical areas. This is accomplished by taking advantage of the patented nano-porous aerogels with ultra-high internal surface areas of >300m2/g and providing properties to minimize conductive and convective heat transfer, providing unparalleled thermal insulation.

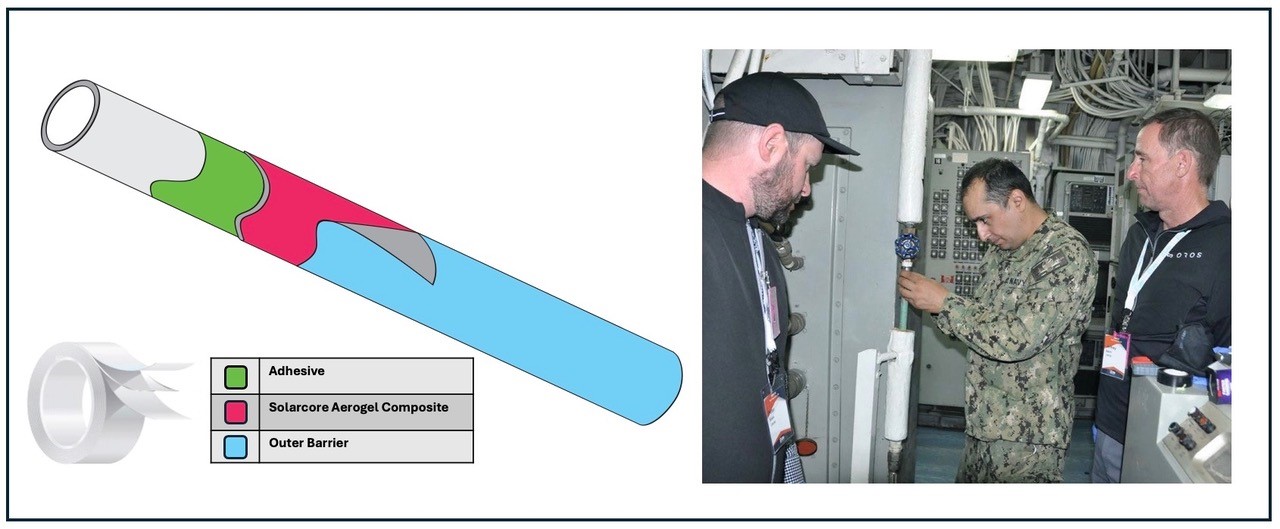

The multi-layer system lagging product consists of an inner dual sided adhesive which is UL 94 FR compliant, an inner Solarcore Nomex/Kevlar aerogel composite, and an outer surface barrier. This product is created for use in exact dimensions for precise fit on chill water pipes, as well as a universal tape solution which can be easily fitted to unexpected shapes and areas.

Current chill water pipe lagging is bulky and takes up valuable space on ships as well as a cumbersome installation process. Solarcore’s materials provide improved thermal efficiency which equates to less use of energy to maintain proper temperatures, space savings from a thinner solution, and easy installation. Characterization data for the aerogel material shows performance gains with a lower profile than existing products and can be installed simply in a matter of seconds for readiness and repairs. Participation at previous Navy repair technology exercises allowed for the demonstration of this product.

These benefits can be used for not just Navy applications, but also in all DoD branches as well as the public domain. Transfer of this technology to the public sector can be easily realized. There are needs for pipe insulation in all aspects of modern infrastructure, home and commercial buildings would greatly benefit from more efficient and thinner insulation solutions reducing energy costs and maximizing useable interior space.

Testing and validation of the product was established by creating a strict protocol using relevant MIL specifications and standards working in coordination with NAVSEA 05T. At the same time the teams worked to create materials in sufficient quantities and configurations that could be used for application and performance analysis in operational environments. This allowed for the sequential advancement of a TRL 2/3 to 5/6; this will continue to be further advanced during future work in Phase IV Advancing Additive Repair Technologies for Sustainment of Maritime Assets.

Graphic