Technology Title

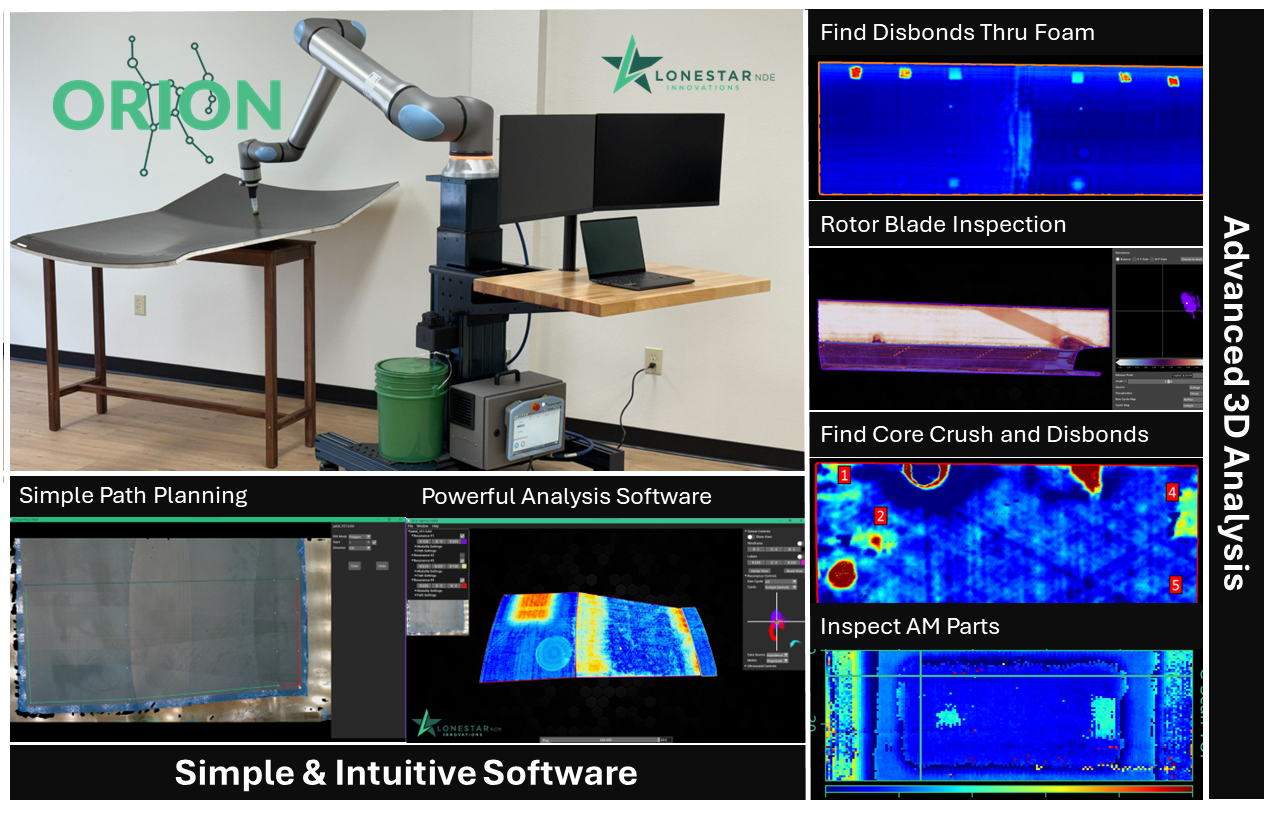

Orion: A Collaborative Robot Inspection System for Advanced Non-Destructive Inspection

Tech Focus Area

Enhanced Inspection

Abstract

Problem Statement: The Department of Defense (DoD) faces significant maintenance challenges with its complex, high-value assets. Current non-destructive inspection (NDI) methods are often labor-intensive and time-consuming, requiring specialized technicians and leading to increased cycle times and reduced asset availability. Inspecting novel materials and complex geometries pushes the limits of conventional techniques, creating a critical need for enhanced inspection solutions.

Description of the Innovation Solution: Orion is a collaborative robot (cobot) inspection system designed to improve NDI efficiency and effectiveness. By integrating bond testing and single-element ultrasonic testing (eddy current planned for Q1 2026), Orion provides multi-modal inspection capability. Its core innovation is a proprietary, CAD-free path planning engine that uses a depth camera and custom algorithms to create inspection plans in minutes, eliminating the need for robotic programmers or coding. This allows Orion to rapidly adapt to high-mix maintenance environments. The system captures high-resolution data (down to 0.02 inches) at speeds up to 40 in/s, recording it in a true 3D, open-source HDF5 format that ensures data ownership and facilitates custom analysis.

Benefits to the DoD: Orion enhances maintenance readiness and reduces costs. Its rapid, automated planning dramatically shortens inspection cycle times. The system’s precision and high-resolution data collection improves the probability of detection for critical defects, enhancing safety and asset integrity. Automating data collection reduces the need for specialized technicians on routine inspections, freeing them for complex data analysis and decision-making. The open-source data format supports the DoD’s goal of data ownership and interoperability, enabling predictive maintenance and digital twin integration.

Innovation Challenges: The primary challenge was creating a robust, CAD-free path planning system for complex surfaces without prior geometric data. This required developing novel algorithms to process data from depth cameras. Future work will focus on expanding inspection techniques and developing additional analysis tools.

Technical Maturity/ Demonstration Results: Orion is technically mature and has been adopted for use by a traditional DoD rotorcraft supplier and a space craft manufacturer. Orion has been successfully demonstrated in relevant applications, detecting disbonds in composite sandwich structures, inspecting 3D-printed titanium structures, and detecting core crush and disbonds in UH-60 blades at an Army repair facility. These demonstrations validate its performance and ability to address pressing DoD maintenance needs. Orion has been prototyped, tested, and refined, confirming deployment feasibility in operational maintenance depots.

Graphic