Technology Title

RepAR: AR Guided Fastener Hole Repair & Validation with Point of Action Data Capture

Tech Focus Area

Enhanced Inspection

Abstract

Problem Statement: Aircraft sustainment teams face three compounding problems: (1) the need for extensive data collection and communication of inspection results, engineering evaluations, and repair actions—each requiring a wide range of skill sets and expertise associated with fastener hole repair, with some structures engineers spending upward of 90% of their time on fastener hole repair; (2) an accelerating shortage of expert maintainers; and (3) limited, auditable evidence needed to justify life-extension credit. The result is elevated MRO labor cost, longer turnaround time, and increased risk to fleet readiness.

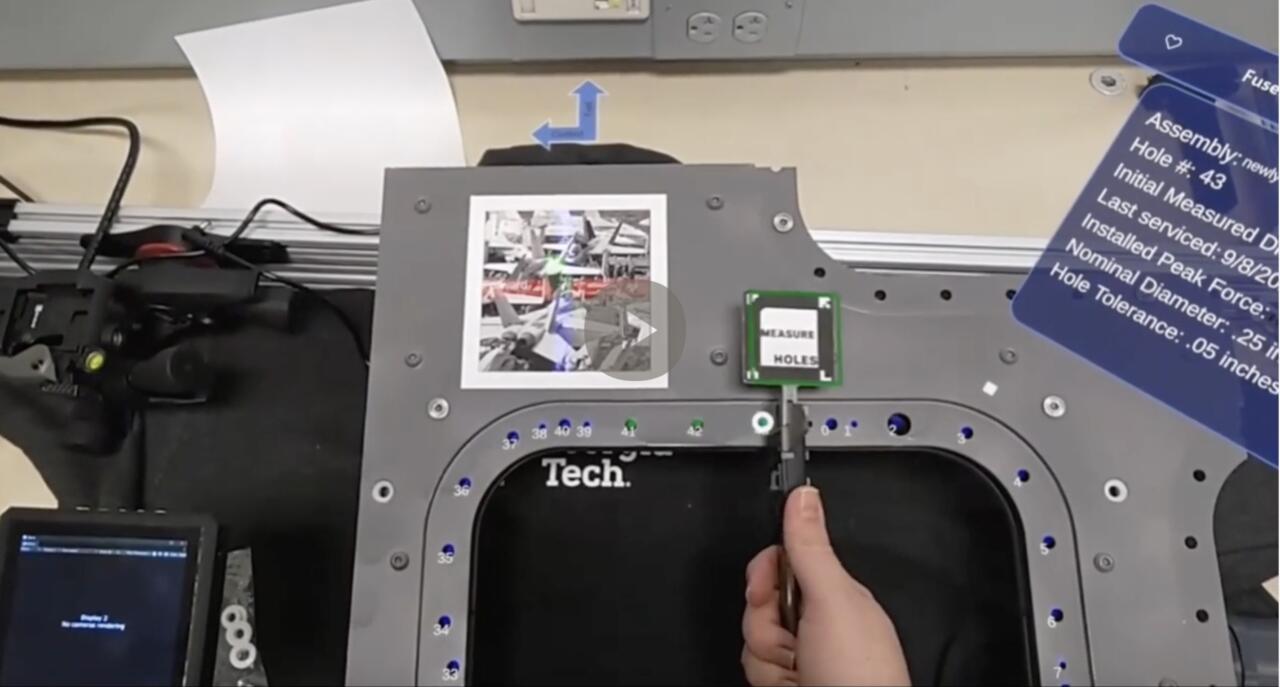

Innovation Description: PartWorks’ RepĀR repair system integrates structural fastener hole repair data capture, augmented reality (AR) work guidance, and AI-powered computer vision with handheld smart tooling and engineered hardware to standardize airframe hole repair, fastener installation, and cold expansion validation. The computer vision system, guided by the mechanic’s designated AOI, identifies holes, assigns coordinates, and records before/after conditions. The system can capture data from any connected tool and user input at time of operation with data logging. Critically, RepĀR updates the digital twin and captures measurements at the “point of action,” creating traceable evidence for airworthiness and A/C life extension credit.

Benefits to DoD: RepĀR directly improves sustainment efficiency by capturing verified data at the point of action—eliminating delays, transcription errors, and disconnected record-keeping. Mechanics can complete inspections, repairs, and installations while automatically generating structured digital records suitable for engineering review, airworthiness documentation, and digital-twin synchronization. This reduces the time engineers spend re-creating or validating field data, shortens repair cycles, and increases the repeatability of fastener hole repairs. By combining AR guidance, AI-based vision analytics, and data-enabled tools, RepĀR supports measurable improvement in throughput, sustainment cost, and higher confidence in overall sustainment processes.

Innovation Challenges: Near term focus areas include qualification data and validation of software and hardware interoperability; cross service interoperability of digital records; NDAA supply chain and cybersecurity compliance for AR devices and data workflows; and validating repeatability across varied depot/flightline environments.

Technical Maturity / Demonstration Results: AR guidance and automated hole identification/measurement has been demonstrated on representative structures; the system architecture is designed for COTS tablets, laptop as well current VR goggles and future VR glasses to provide hands free environment with minimal interruption to the workflow. System has been demonstrated to multiple military and commercial entities.

Graphic