Technology Title

Millimeter/micrometer Wave Inspection System for Thick Polymer Coatings

Tech Focus Area

Coatings/Corrosion Prevention

Abstract

Problem Statement: There is currently no method for nondestructive testing (NDT) of metal substrate health through thick polymers applied to the hulls of different USN warships. Current methods for inspections through thick polymers involve the costly destructive removal of sections of the thick polymer generating hazardous waste and wasting time labor, time, and materials. A nondestructive imaging method for inspections of the metallic substrates through thick polymers is needed to reduce lifecycle costs, improve accuracy of initial maintenance work scoping, and increase operational readiness by reducing emergent maintenance issues in-field that were not discovered during scheduled maintenance.

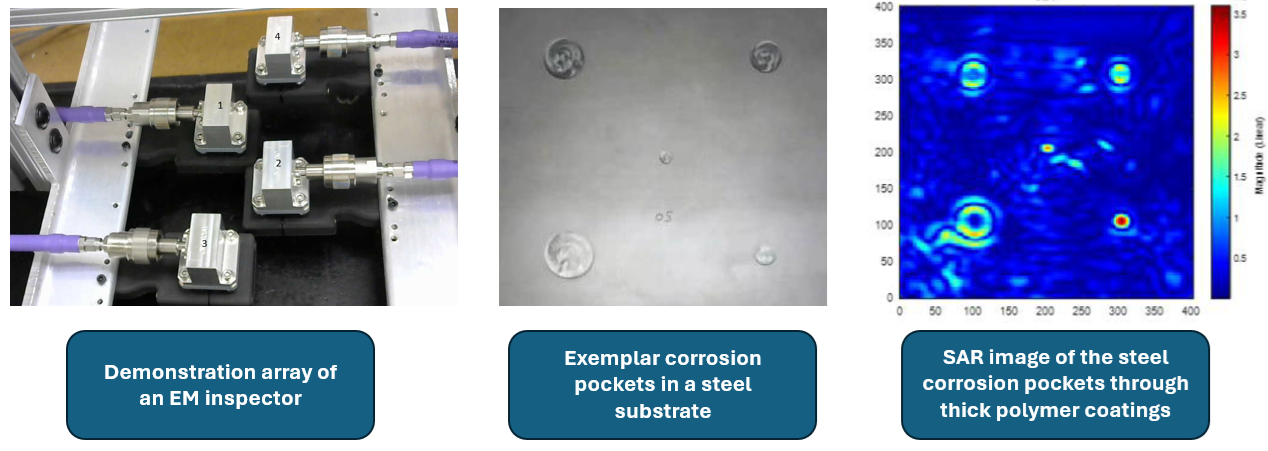

Innovative Solution: Electromagnetic (micro/millimeter wave) imagers offer the ability to inspect through different materials in the high MHz to low GHz frequency range, including thick polymer coatings and build images of the substrate surface, including signs of corrosion and other defects. The inspection system uses synthetic aperture radar (SAR) produced by multiple custom designed antennas operating exclusively as transmitters or receivers with low noise amplification to form an overall inspection array. Corrosion patches have been successfully identified underneath polymer layers using this system on steel substrates of interest. Previous iterations of microwave/millimeter wave imagers such as these have been packaged and delivered to customers.

Benefits to the Military: Presently, there are no ways to provide maintainers with information about areas that may require maintenance under thick polymer coatings on metallic hulls. Electromagnetic imaging systems, such as the one being developed for USN for these targets, will provide maintainers information about areas of hulls that do need destructive removal of polymers for visual inspections. The ability to significantly cut down the amount of material removed offers large amounts of cost and time savings when qualifying these weapon systems during periodic maintenance. This will enable higher safe availability of USN weapon systems. In addition, variations of this technology can examine a wide range of different non-electrically conductive material systems, such as ablatives, coatings, composites, and many others.

Technology Maturity: This solution produced by TRI Austin has been demonstrated on various laboratory experimental setups as well as specimens provided by USN. As mentioned, the system can inspect through wide ranges of different material systems. Present iterations of this technology have reached TRL 5 (for highly fidelity testing of integrated laboratory components) with additional demonstrations of USN specimens of interest planned.

Graphic