CTMA Project #: 140499

Problem: The USAF T56 engine Program Office implemented the Workscope Cost Optimizing Tool (WCOT)™ in 2006. This tool recommends optimal repair workscopes based on the underlying reliability and cost of repair options. The success of the program in improving T56 reliability has been directly tied to the quantity and quality of data collected at the depot and in the field through the use of the Maintenance In-Depth Maintenance Data Collection System (MIDCS) database within the USAF’s Data Repository Center (DRC).

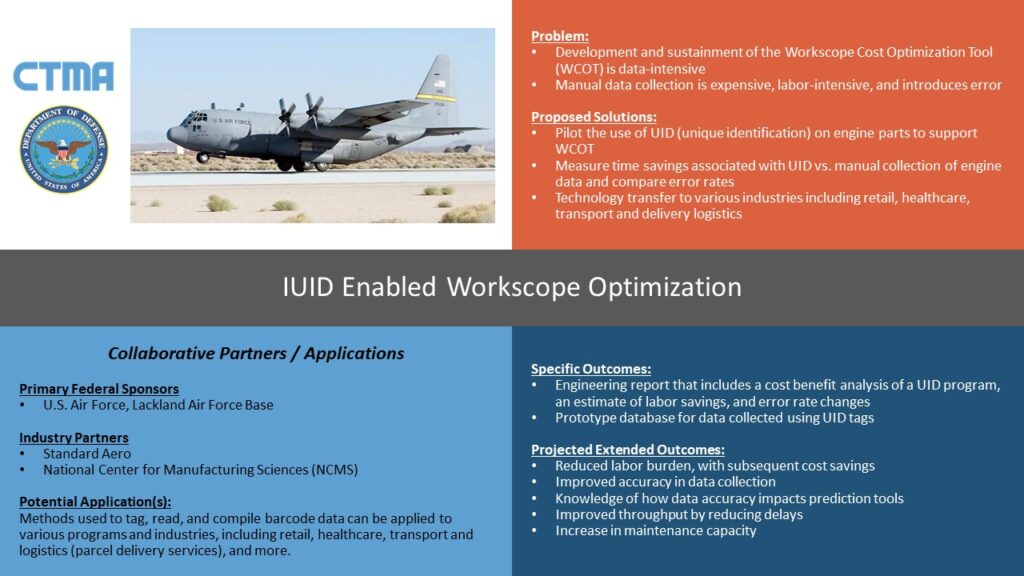

The development and sustainment of the Workscope Cost Optimization Tool™ is data-intensive. The removal times and observed failure modes of numerous engine parts must be manually collected, not only at the depot, but also at Intermediate Repair sites. Manual data collection creates two significant problems. First, it introduces error through the incorrect recordings that are transcribed and entered into government systems. Secondly, it is expensive. Not only are serial numbers written down, but they are subsequently key-punched into databases. The burden this places on field units is substantial and consequently, requests to track additional engine parts are often rejected by the field simply because the data recording process is so labor-intensive.

Benefit: The use of UID tagging and data collections methods will benefit the DoD in three ways:

- Reduced labor burden on the field level personnel, with subsequent cost savings.

- Improved accuracy in the data collection efforts.

- Provide an understanding as to how data accuracy impacts the accuracy of existing and future prediction tools.

Solution/Approach: Under this project, the collection of engine component reliability data through UID means will be piloted. Specifically, this project will:

- Pilot, and if necessary, simulate the use of UID on engine parts to support the Workscope Cost Optimization Tool™ development process.

- Measure the time savings associated with the use of UID vs. manual collection of engine data.

- Measure and compare the error rates of manually and UID collected data sets. In this regard, the project will refer to previous work that baselined the errors in the reliability data sets.

- If appropriate, build a business case for the widespread adoption of UID as a way to improve data quality and reduce the cost of data collection.

- The work will be accomplished on engines that are using the workscoping tools currently within the AMC and AFSOC Commands.

- UID data will be downloaded directly into the USAF’s reliability MIDCS data base at each event. This will prevent the need for USAF personnel to document the component details at each removal event.

This process will set the path for tracking components relevant to engine reliability and cost without burdening maintainers, resulting in further cost savings from current implementation efforts.

Quad Chart:

Impact on Warfighter:

Improved logistics tracking and engine reliability.

The use of UID can greatly enhance the level of data collection, while maintaining integrity and reducing the burden on the war fighter.

Reductions in the time required to collect component data in the field will improve throughput in the shops by reducing delays. The reduction in time required to collect the data will free personnel for other duties, possible resulting in an increase in maintenance capacity.

DoD Participation:

- U.S. Air Force (Lackland AFB)

Industry Participation:

- StandardAero

- Source Code, LLC

- NCMS

Benefit Area(s):

- Cost savings

- Maintenance management improvement

- Improved readiness