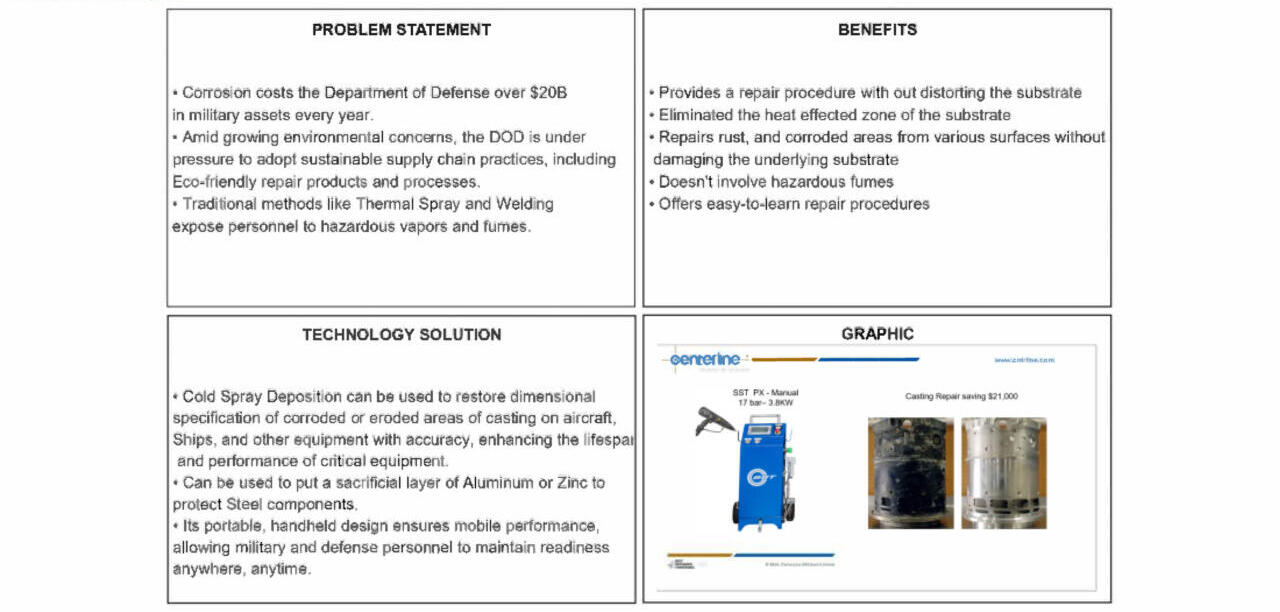

CenterLine’s Supersonic Spray Technologies (SST) designs & manufactures a full range of patented cold-spray metal coating systems for the aerospace, defense, glass and automotive industries.

Cold spray is a cost-effective and practical coating process that is considered part of the Thermal Spray family. The cold spray process enables users to apply robust metal coatings to a wide range of surfaces without melting. Coating characteristics include extremely low oxide entrapment, high densities and high bond/cohesive strengths. Cold spray coatings are extremely machinable (with conventional tooling), have thin or thick build characteristics and are accepting of dissimilar materials with no galvanic reactions.

The SST division also supplies a range of OEM production applications and job shop services to protect, repair, restore, refinish and recoat manufactured products. The SST Cold Spray™ process can be used in many industries including Aviation, Automotive, Heavy Machinery, Energy, Manufacturing, Architectural, Naval Air and Sea Equipment and many others. The process enables a broad range of coating and metal consolidation applications, in particular, many that may not be possible or commercially practical with other processes. Along with the SST equipment, SST cold-spray grade feedstock powders are ideal for applications ranging from dimensional restoration, thermal dissipation, electrical conductivity, corrosion protection, sealing, surface cleaning, and many others.

Focus Area: Advanced/Additive Manufacturing

Contact

Wally Birtch

wally.birtch@cntrline.com

248–217–1173

Cold Spray Technology