Technology Title

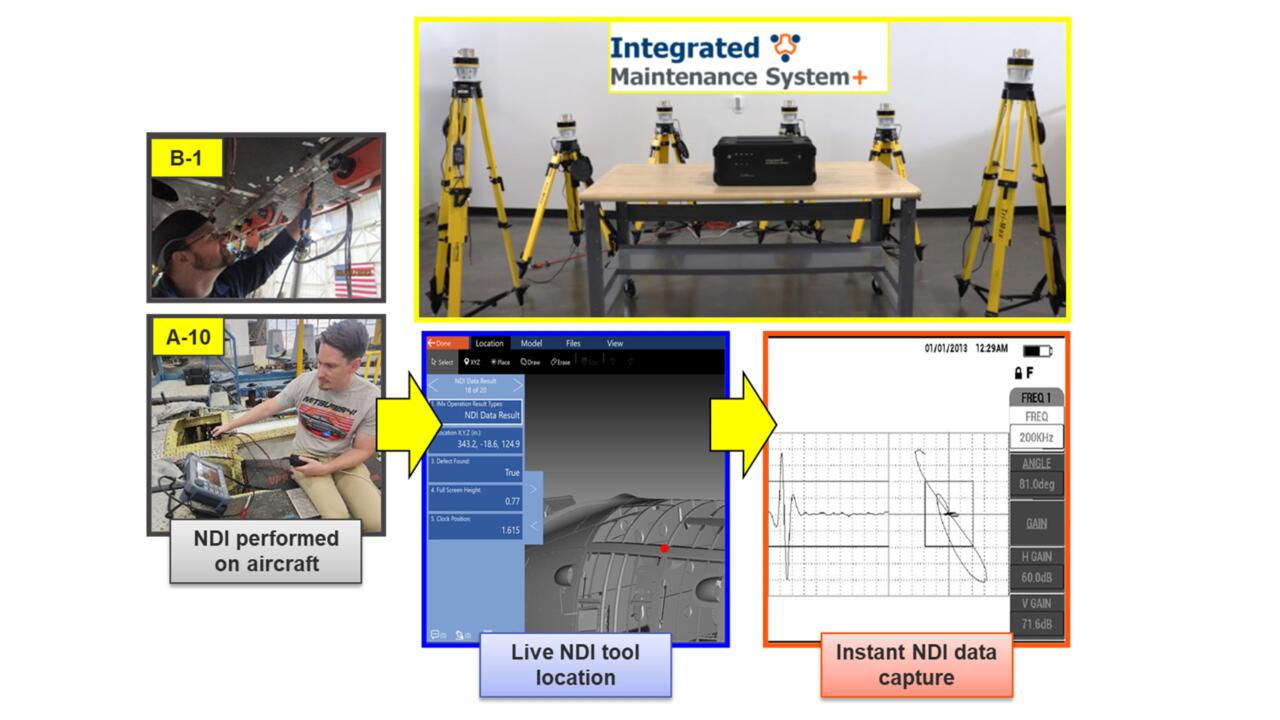

Ensuring Aircraft Structural Integrity with the Integrated Maintenance System (IMx+)

Tech Focus Area

Expeditionary Repair of aircraft structural components

Abstract

Problem Statement: Nondestructive inspection (NDI) is a critical aspect to safely and efficiently manage structural integrity, however, current procedures being used are manual and inefficient. Hand recording of results, transcribing to other systems, and redundant work results in longer engineering disposition turnaround times, missing and/or incomplete data, and reduced confidence in correct execution of tasks. Adoption and use of automated NDI data capture methods, coupled with digital twin models of the aircraft, are key to improved depot efficiency and aircraft structural integrity management.

Description: An innovative solution for enhancing expeditionary repair is the Integrated Maintenance System (IMx+). It automates NDI data collection straight from the shop floor inspection tools, relates this data to the actual (x,y,z) spatial position of the maintenance event, and integrates that data into a 3D digital twin model of the aircraft. This expedites the inspection process and decreases time to both capture and document results. IMx+ also provides real-time visual feedback to the maintainer, ensuring 100% accountability of inspections performed.

Graphic

The system is highly portable. It is transportable by one person on a shop floor cart and can be set up and running within 30 minutes and is designed for ruggedized use in the depot environment. The entire system is approved for use on the USAF NIPRnet and has an approved Authority to Operate (ATO). The IMx+ system represents a new state-of-the-art capability for automated data capture of critical maintenance data, integrated automated data capture and long-term storage of the digital thread. Also, approved integration with the USAF NIPRnet expedites and automated the data capture process, eliminated the current process of off-network devices or manual transcribing of data into maintenance information systems.

Benefits: With annual DoD depot maintenance costs expected to exceed $30B in FY25, increased efficiencies can result in significant cost savings. Based on USAF depot usage, utilization of the IMx+ system provides ~20% reduction in inspection time through real time feedback and ~50% reduction in time to document inspection results. These benefits are not limited to the USAF – the system has cross-service applicability to easily transition for use in other DoD depot environments.

Challenges: The USAF uses a variety of tools on the shop floor to support various maintenance requirements, all of which have differing abilities to capture and share data. These tools vary by depot location and evolve over time. Instead of developing the system for a fixed set of tools, the IMx+ system utilizes a modular API framework, allowing flexibility to add new tools in a plug-and-play type connection.

Maturity: IMx+ is at a TRL 9 and is currently being utilized by depot maintenance at Hill AFB for A-10 and F-16, with upcoming implementation for F-35 depot maintenance and B-1 full-scale testing at Boeing