Technology Title

The Future of Bolting is Hands-Free

Tech Focus Area

Robotics and Automation

Abstract

Nexterity provides automated tools for rapid, reliable, and safe maintenance of military assets in a manner that reduces human risk, minimizes downtime, and ensures mission readiness. The U.S. Department of Defense (DoD) generally relies on manual bolting operations across flanged piping systems, water supply lines, fuel delivery systems, wheeled vehicles, and other critical infrastructure. Manual bolting requires repetitive manual labor, exposes personnel to hazardous conditions, and risks human error. Errors can lead to equipment failure, incomplete work, and accidents. Nexterity provides automation to alleviate these challenges.

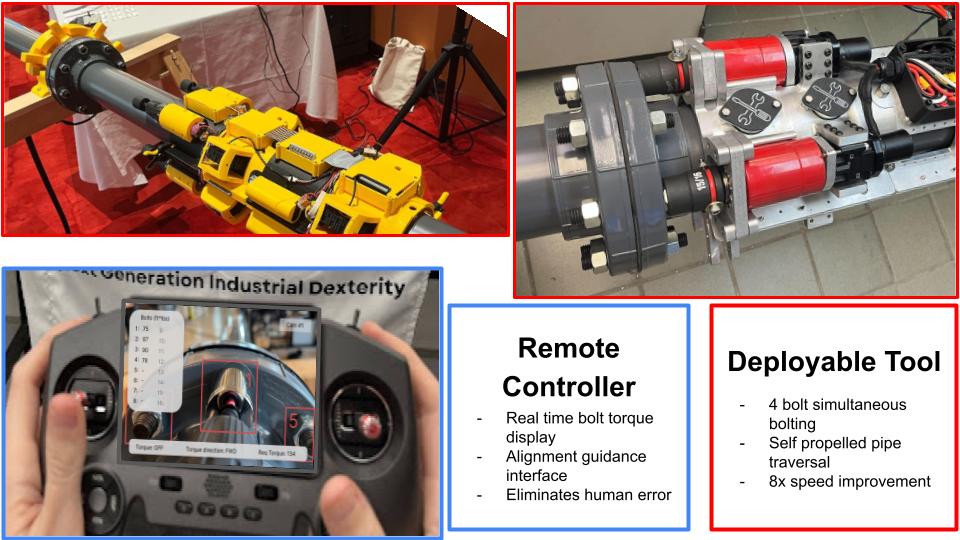

The company has designed a hands-free, automated tool for bolting operations. Leveraging advanced sensing technologies, computer vision, and precision torque control, Nexterity’s first generation robot can apply consistent torque and operate in confined or challenging spaces. The first generation product targets circular bolt patterns such as those on tires and on pipe flanges. Operators align the tool with the target bolts, step back, and use a controller to conduct bolting/unbolting. The tool applies operator-specified torque simultaneously to four orthogonally opposed bolts. The tool can be rotated remotely to complete bolting operations in 4, 8, 12, or 16+ bolting patterns.

Graphic

This solution directly benefits the Department of Defense by enhancing human operator capacity and improving bolting quality. A single human operator using Nexterity’s products can complete many simultaneous bolting operations, freeing up personnel to perform higher-value tasks. Additionally, reducing human exposure to pinch points, pressurized connectors, and confined areas lowers injury risk for maintenance workers. Further, the product is faster and more accurate than manual bolting, which can decrease downtime on critical systems, minimize joint stress driving accelerated infrastructure degradation and improve overall equipment readiness. Future generations of the product will be designed to autonomously navigate piping to reach target maintenance or repair zones, driving additional efficiencies. Sample applications include fluid and fuel line repairs on ships, aircraft, and ground vehicles; and bolting for tire replacement for military vehicles in depots.

The product has been demonstrated in controlled environments after multiple rounds of prototyping and iterative development. It is set for commercial field tests in flanged piping in industrial plants in Spring 2025. The company has also scheduled assessment in a bolting lab in June 2025 to quantify performance and quality. In early Summer, Nexterity will begin adapting the tool for use in Army Depot tire bolting operations via an SBIR project. New applications of this product will require developing context-specific operational protocols, updating computer vision algorithms, and potentially adapting the tool’s form factor or accessories. For example, due to the tool’s design being