Technology Title

DADTMA (Distributed Acquisition Digital Twin Maintenance Architecture)

Tech Focus Area

Expeditionary Repair of aircraft structural components

Abstract

Traditional MRO practices in the DoD are struggling to adapt to the increasing complexity of aircraft maintenance and quality assurance processes, including the use of scanning, digital tools, and modeling technologies to capture maintenance data and automate workflow management. Of paramount importance is validation that all parts and assemblies are free of anomalies which could cause failures and increased life-cycle costs. The current process is inefficient, requiring time-intensive human-performed inspections and data collection before, during, and after maintenance tasks. The process frequently requires tedious and error-prone record keeping with pen and paper before transcription to a computer for access by other teams or departments.

FTL’s DADTMA (Distributed Acquisition Digital Twin Maintenance Architecture) has been developed in close collaboration with the Navy Fleet Readiness Center Southeast (FRC-SE) T-45 aircraft depot, in response to their immediate need to relieve onerous aircraft repair and maintenance tracking arising from limited manpower resources in maintaining aircraft repair and redeployment tempos.

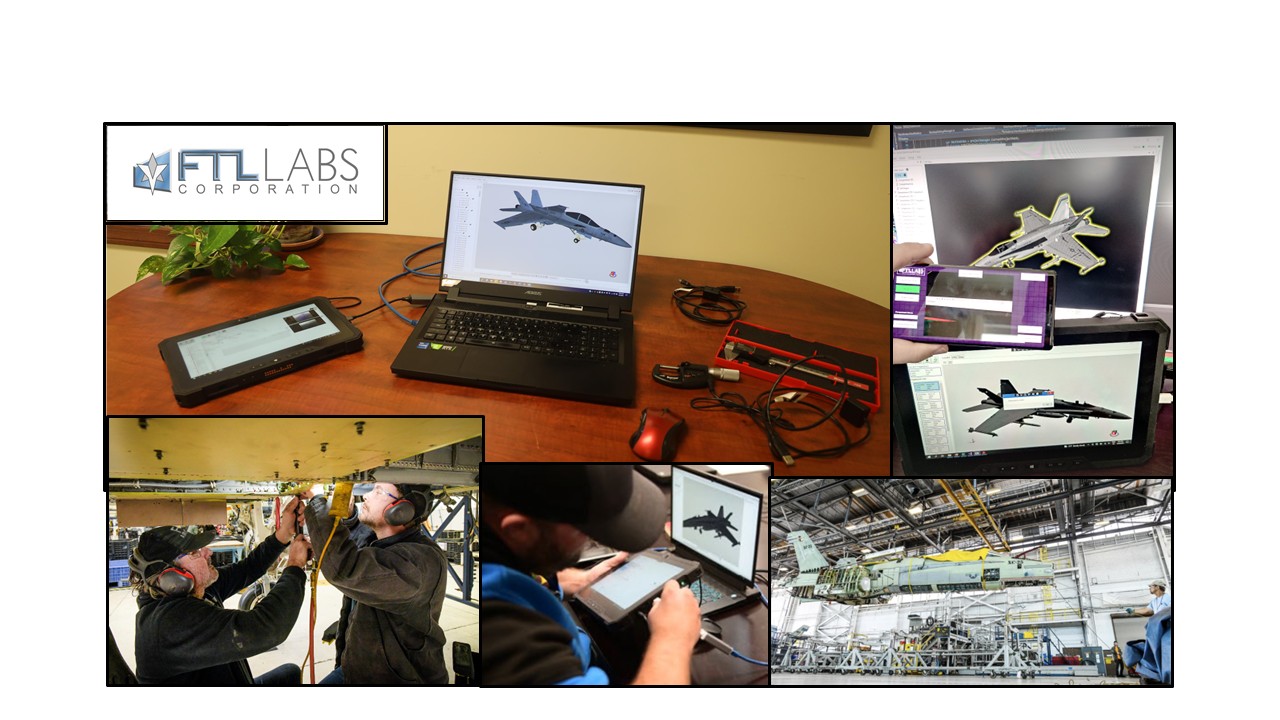

Graphic

DADTMA tablet and web apps work together to accelerate and automate inspection data collection, streamline data sharing, and provide tools for predicting maintenance requirements by utilizing a secure digital twin graph database, big data mining, and AI on a GovCloud web app. Maintenance requirements and actions can be quickly tracked and cross-referenced across similar aircraft or on a single aircraft across multiple maintenance events. Additionally, required maintenance on specific parts can be predicted based on prior service patterns. This data can be quickly accessed across departments, DoD components, or with outside manufacturers and PLM providers.

DADTMA is currently being funded by a follow-on phase II SBIR. The DADTMAinspect tablet app is currently at TRL7-8 and has been DADMS approved for use on Navy tablets at the FRC-SE aircraft depot, where it is being used to automate data collection by integrating USB tools such as calipers, bore gauges, and borescopes. That data is saved in the DADTMAinspect tablet app under Findings along with annotations, notes, photos, 3D images and maintenance documents.

The optimal transition path for the DADTMA app would be for its continued use as FRC-SE with adoption across all FRCs and possibly Navy shipyards. DADTMA is data-agnostic and can be used to save maintenance time and manpower for any high value asset. During development, FTL sought direct input from aerospace manufacturers Lockheed Martin, Sikorsky, and Northrop Grumman. Applications include the U.S. Department of Defense and civilian aerospace markets and large-scale manufacturing, such as for heavy machinery, medical devices, and silicon chips. Northrop Grumman anticipates a 10% time-reduction in inspections, yielding $10M in savings in lifecycle cost for a single product.