Technology Title

Atmospheric plasma surface preparation for aerospace hydraulic components

Tech Focus Area

Surface Preparation and Corrosion Control

Abstract

Aerospace hydraulic components present persistent sustainment challenges due to the durability of their epoxy-based protective coatings and the complex geometries of parts such as fittings, housings, and internal channels. Conventional coating removal techniques—manual abrasion and abrasive blasting—are labor-intensive, inconsistent, and pose risks of damaging precision-machined surfaces or leaving residues that compromise re-coating adhesion. This work introduces a non-contact, atmospheric plasma technology as an innovative, automation-compatible alternative for epoxy removal and surface preparation of metallic aerospace components.

The atmospheric plasma process uses ionized gas at ambient pressure to chemically oxidize organic coatings while simultaneously activating the metal substrate for improved re-coating adhesion. Unlike mechanical methods, atmospheric plasma surface preparation is residue-free, low-temperature, and capable of conformally treating intricate surfaces with minimal operator involvement. Controlled laboratory on MIL-spec epoxy-coated aluminum and stainless-steel hydraulic components demonstrated complete coating removal without surface damage or thermal distortion. Post-treatment surfaces exhibit enhanced wettability and oxide formation, resulting in an increase in coating adhesion strength compared to conventional manual surface prep.

Graphic

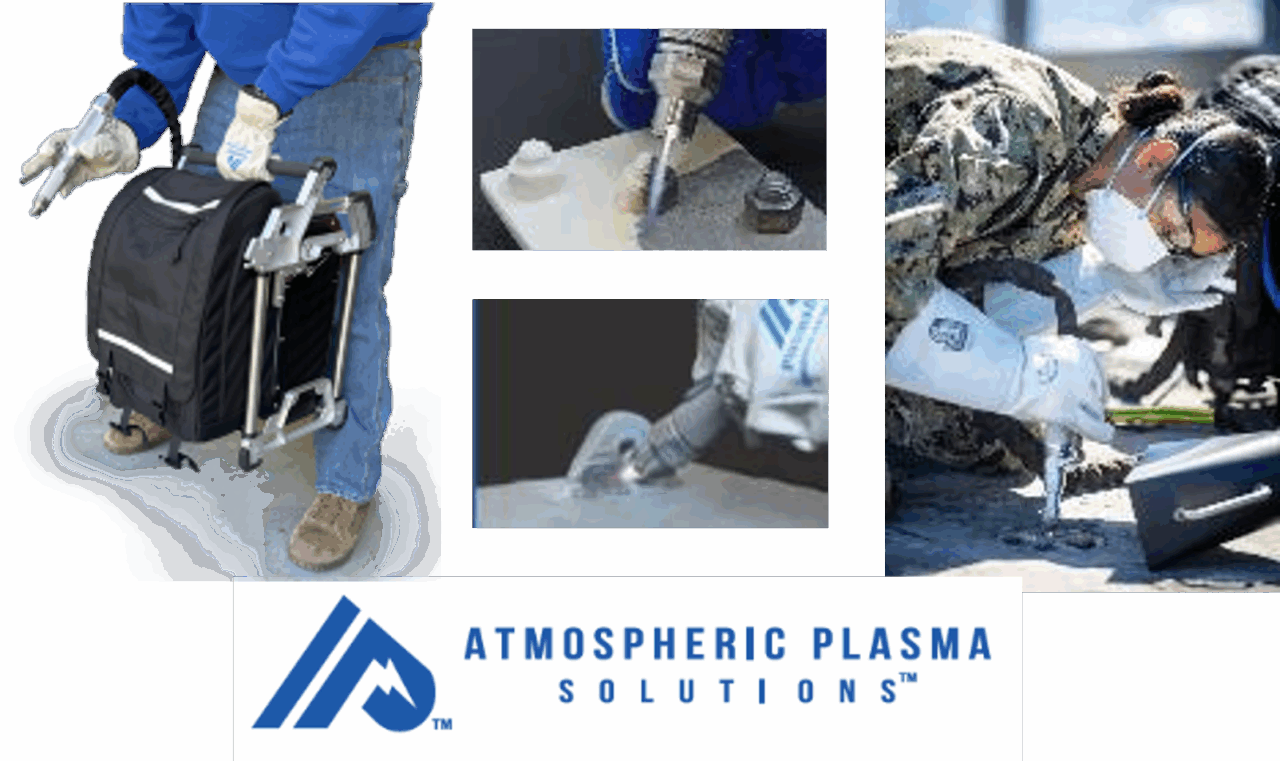

This technology significantly advances maintenance efficiency by eliminating the use of abrasives and solvents, reducing cycle time, and enabling highly repeatable surface conditioning. It also improves safety by minimizing operator exposure to dust, chemicals, and repetitive physical tasks. The system is designed for either handheld deployment or integration with robotic or collaborative robotic arms, supporting continuous operations in high-throughput depot environments with reduced manpower requirements.

From a technical maturity perspective, this atmospheric plasma solution has achieved Technology Readiness Level (TRL) 9. It has been successfully demonstrated in field environments on representative aerospace systems and shown to be compatible with existing re-coating processes. The modular system is scalable, supports varied geometries, and requires minimal infrastructure changes, making it readily deployable within DoD maintenance operations.

The approach is broadly applicable across all service branches and is currently being implemented throughout DoD. Its non-contact nature, clean process, and minimal environmental footprint support deployment in depot, field, and shipboard settings. Environmental compliance is simplified by eliminating blasting media and hazardous waste streams, aligning with DoD sustainability goals.

A clear transition path is supported by ongoing integration with DoD maintenance stakeholders, including OEM and logistics partners. The system is compatible with existing digital maintenance workflows and work instructions.

Video Submission

https://apsplasma.wistia.com/medias/5diu1znzth