Technology Title

How Raptor RFID can facilitate Expeditionary Repair of Aircraft Structural Components

Tech Focus Area

Expeditionary Repair of aircraft structural components

Abstract

Problem Statement:

Expeditionary repair operations require rapid access to parts and tools, but asset visibility in forward-deployed environments is limited. Inventory processes are slow, unreliable, and ill-suited for non-permanent structures and improvised storage zones. To maintain readiness and mission effectiveness, the DoD needs a reliable, low-maintenance inventory solution that ensures accuracy and traceability during structural repairs, especially in remote locations where speed and flexibility are essential.

Description of the Innovative Solution:

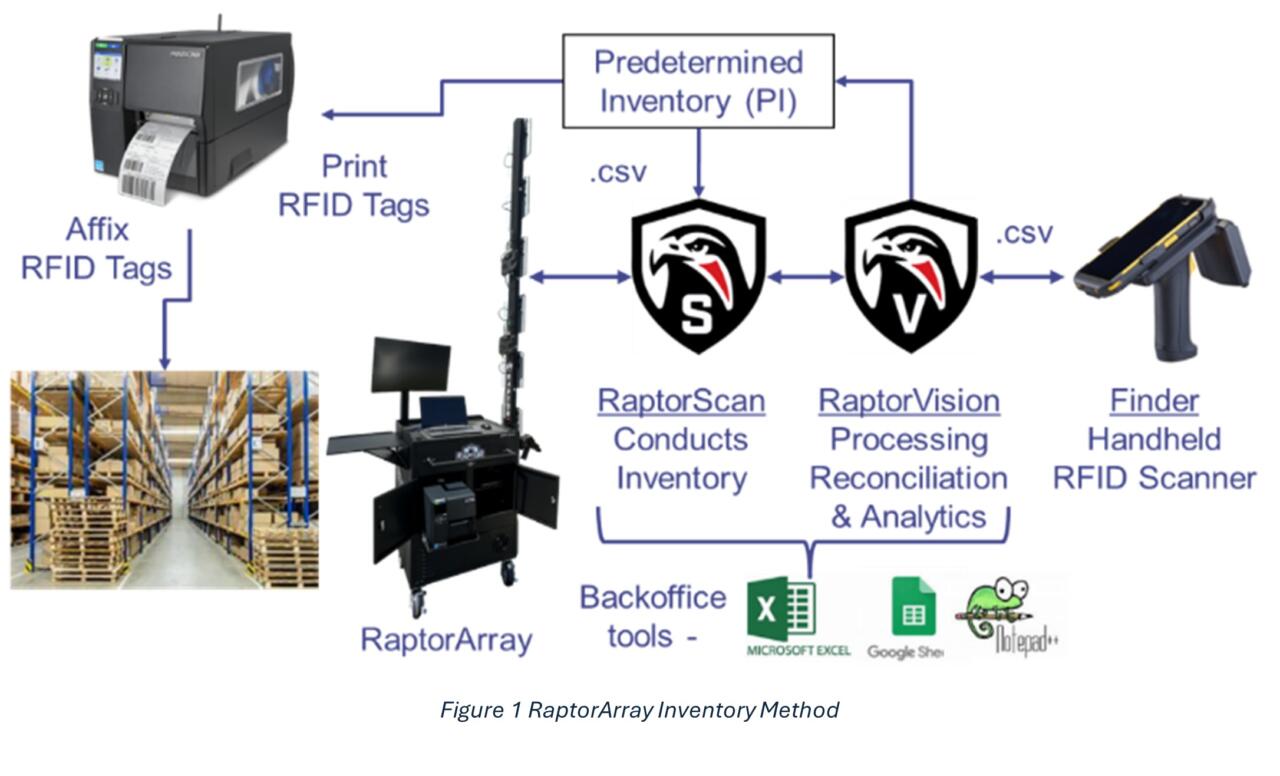

RaptorRFID provides a rugged, field-ready RFID inventory automation system designed for fast deployment and operational use in challenging environments. The platform includes:

- RaptorArray: A mobile cart-based RFID scanner that conducts high-speed, high-volume asset scans in warehouse or temporary storage areas. Ideal for SSA sites supporting forward repair operations.

- RaptorHandheld: A compact RFID scanner with Finder Mode for field use, enabling rapid asset location and discrepancy resolution in dynamic or remote environments.

Graphic

These tools support the full asset lifecycle during structural component repair, including intake verification, location tracking during maintenance, and reconciliation at re-issuance.

RaptorRFID’s patent pending software suite includes:

RaptorScan: Interface for inventory scanning and tagging on both laptops and handheld devices

RaptorVision: Tool for detecting discrepancies and generating heat map analytics

All systems use standard CSV files, allowing compatibility with WMS platforms and field laptops. No network configuration or persistent connectivity is required, making the system ideal for secure and disconnected environments.

Benefits to the DoD:

Portability: Ships in containers and assembles in under two hours with basic tools

Self-Sufficiency: Mobile and Operates on battery without IT support

Operational Accuracy: Delivers 100% inventory accuracy in remote locations

Seamless Integration: Syncs with base-level systems via USB or secure cloud storage

Secure, scalable Enterprise support for enterprise-wide operations using cloud storage (e.g., OneDrive)

Improved Repair Workflow: Speeds part location and reconciliation, supporting critical timelines in aircraft repair

Innovation Challenges:

Traditional RTLS solutions depend on fixed infrastructure, detailed mapping, and IT support. RaptorRFID eliminates these barriers by offering a rugged, intuitive system that requires no permanent setup or external support. It is specifically designed for mobile teams and dynamic repair environments.

Technical Maturity / Demonstration Results:

The RaptorRFID suite is in pre-deployment pilot phase. Tools have been validated in warehouse simulations, including asset movement scenarios typical of aviation maintenance. The patent-pending technology is being prepared for live demonstrations at government facilities. Learn more at www.raptorrfid.com.

Video Submission

https://vimeo.com/1084407379?share=copy