The University of Southern Mississippi (USM) School of Polymer Science and Engineering (SPSE) offers DoD a defense friendly university R&D infrastructure at the CUI level of security. DOD programs span “basic research through technology demonstration” and focus upon rapid development of strategic priorities for next generation polymers, composites and coatings. We maintain a team of ten full-time US citizen professionals with an average >17 years of experience who manage a unique advanced development infrastructure designed to accelerate the advancement of strategic polymer materials needs for the US military. We maintain long-standing relations with DOD program managers and defense laboratories to cultivate cross-functional USM-defense personnel team communications, coordination of personnel and project prioritization, streamlined resource/project management techniques that expedite material development timelines, and coordinated budgetary actions to rapidly achieve go- or no-go decisions. We strive to uphold perpetual assessments of promising new technologies that expedite field-level demonstration for validation of performance protocols established by DOD. USM excels in the laboratory-to-pilot-scale field demonstrations for polymer, composite and coating materials combined with advanced development capabilities for processing, part fabrication, product/process engineering, material and part specifications, and health & environmental safety.

Focus Area: Energy, Environmental, Health, and Safety

Contact

Jeff Wiggins

jeffrey.wiggins@usm.edu

601-266-6960

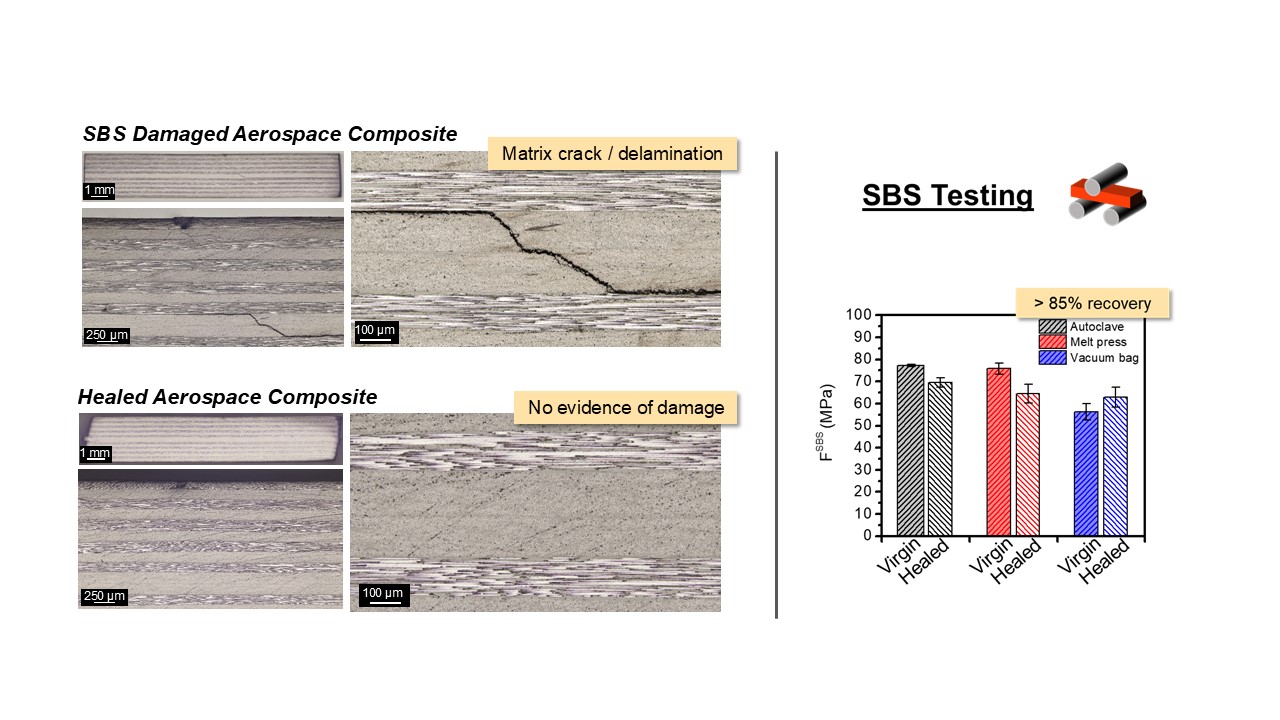

Composite Repair & Manufacture

Problem Statement:

COMPOSITE REPAIR AND MANUFACTURING

- Repair of Composite Structures Requires Is Time Consuming and Cost Prohibitive

- Traditional Crosslinked Thermoset Polymer Composite Matrix Chemistries Do Not Repair

- Composite Repair Methods are Time Consuming and Cost Restrictive

- Field Repair of Composite Structures is Very Difficult

- Repair Techniques are Limited by Durability and Performance Requirements

- Inspection of Damaged Zone Areas is Challenging

- Repair Requires Highly Skilled Personnel, New Materials and Difficult in the Field

- Composite Damage Often Requires Detection and Repair Experts

Benefits Statement:

COMPOSITE REPAIR AND MANUFACTURING

- Solvent and Chemical Free Repair Approach

- Low-Cost Repair Capability

- Same Repair Technique Applied to All Structural Product Forms

- No Chemical Reactions or Condensates

- High Strength Repairs in a Broad Range of Field Requirements

- Repeated Repairs Shows a High Degree of Healing Efficiency

- Thermally Stable Repairs to Original Capability

- Fast and Effective Field Repair Feasibility

- Eliminates Solvents, Chemicals and Harsh Environmental Concerns

- Provides Simplicity with Remarkable Modularity and Tailorability

- Pilot Scale Demonstration and Favorable Economics

Technology Solution Statement:

COMPOSITE REPAIR AND MANUFACTURING

- Self-Healing High Strength Vitrimer Polymers Are Thermally Repaired In-Place

- Heating Blankets and Low-Pressure Structural Repairs are Feasible

- Repair Methods are Fast, Reliable and Low Cost for >85% Original Strength Recovery

- Repair Methods are Capable to be Performed in the Field With Limited Technical Knowledge

- Repair Methods are Immediate and Do Not Require Special Preparation or Materials

- Repair Methods Do Not Require Advanced Tools or Techniques

- Repair Methods are Feasible in a Broad Range of Physical Environments