The University of Southern Mississippi (USM) School of Polymer Science and Engineering (SPSE) offers DoD a defense friendly university R&D infrastructure at the CUI level of security. DOD programs span “basic research through technology demonstration” and focus upon rapid development of strategic priorities for next generation polymers, composites and coatings. We maintain a team of ten full-time US citizen professionals with an average >17 years of experience who manage a unique advanced development infrastructure designed to accelerate the advancement of strategic polymer materials needs for the US military. We maintain long-standing relations with DOD program managers and defense laboratories to cultivate cross-functional USM-defense personnel team communications, coordination of personnel and project prioritization, streamlined resource/project management techniques that expedite material development timelines, and coordinated budgetary actions to rapidly achieve go- or no-go decisions. We strive to uphold perpetual assessments of promising new technologies that expedite field-level demonstration for validation of performance protocols established by DOD. USM excels in the laboratory-to-pilot-scale field demonstrations for polymer, composite and coating materials combined with advanced development capabilities for processing, part fabrication, product/process engineering, material and part specifications, and health & environmental safety.

Focus Area: Coating and Corrosion Prevention

Contact

Jeff Wiggins

jeffrey.wiggins@usm.edu

601-266-6960

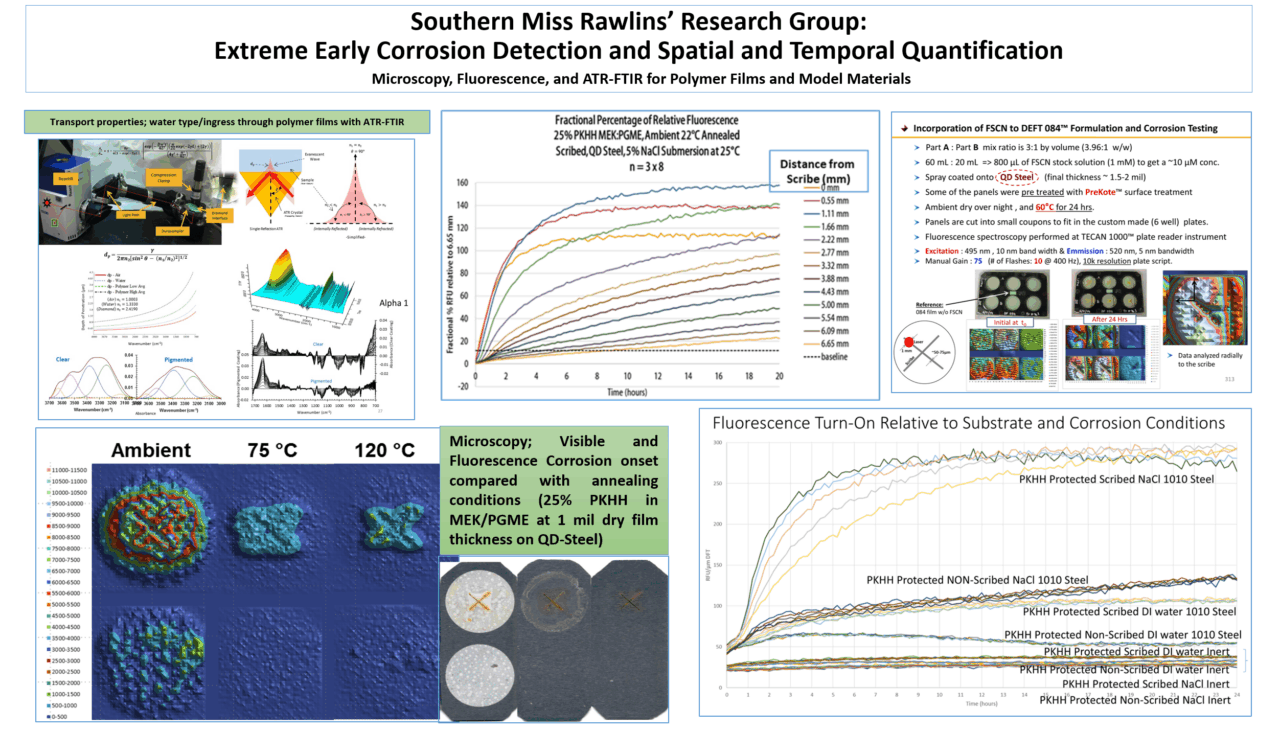

Early Corrosion Detection and Prevention

Problem Statement:

Corrosion control/prevention science is stagnated without a direct and discernable method to detect and quantify the effects of substrate, coating formulation, application, annealing/cure, layering, and environmental conditions in situ. The primary coatings research achievements were systematic and incremental improvements in asset preservation, which unfortunately, reduced the rate of development or eliminated many new technology advances.

Benefits Statement:

The measurement and evaluation protocol using applied location specific fluorescence characterization of coated substrates, measures corrosion initiation, corrosion onset, migration, and spatial and temporal corrosion rates most often detected within 24 hours. Substrate-polymer combinations also exhibit self-passivation under certain conditions when the electrolyte, oxygen or water content are managed appropriately. These methods will provide direct and definitive quantification and understanding of the polymer corrosion protection process.

Technology Solution Statement:

We have developed a reliable early corrosion detection and quantification characterization protocol that discerns between spatial and temporal metal dissolution rates for polymer coated substrates with/without intentional defects. Reflectance fluorescence detects and quantifies pH changes associated with corrosion onset and migration e.g., SAE 1010 steel and has been applied to oxygen, water, substrate, polymer variables with success in measurement within 24 hours. The adaptable approach includes electrolyte type and concentration, substrate composition and defect analysis from a variety of fluorescent indicators at low concentrations (0.002 wt. %, 10 µM) within a coating in a passive (more like nature) rather than active (EIS) manner. We propose to define the controlling variables for corrosion processes and corrosion prevention with our current emphasis on measuring differences between substrate preparation mode/methods, polymer type/structure/properties, application conditions, and cure/annealing processes, plasticizer and solvent effects on performance, and environmental conditions each individually.

Dramatic cost savings for novel material development and conventional material assessments.