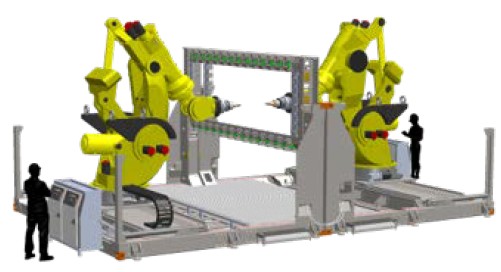

Machina’s Robotic Craftsman is an agile manufacturing platform integrating 7-axis robots, autonomous sheet loading and fixturing, and advanced AI process models and closed-loop controls to enable many manufacturing processes at the click of a button. The robots have the ability to change tools and sensors instantly to perform a variety of operations such as roboforming, scanning, and trimming on a wide range of materials. The platform is continuously upgraded to improve existing capabilities and add entirely new ones.

Focus Area: Advanced/Additive Manufacturing

Contact

Matt Ragan

POC Email: matt.ragan@machinalabs.ai

POC Telephone: 757-971-1379

Robotic Incremental Sheetmetal Forming

Problem Statement:

The DOD continues to face overwhelming challenges in limited availability of mission ready defense systems. Missions are being compromised by antiquated manufacturing equipment, outdated supply chains and slow parts replacement times. These constraints impede the maintainer’s ability to address needed repairs quickly. A review by the U.S. Government Accountability Office (GAO) of 49 different defense aircrafts for 2011-2021 found that ONLY FOUR MET READINESS GOALS MOST YEARS and 26 did not meet their goals in any year.

Technology Solution Statement:

Robocraftsman Capability Description:

- Metal forming, trimming, hole cutting, drilling, and laser scanning (QC) capability (TRL 7)

- Containerized, two containers mate up to assemble the full system

- Rapidly-deployable via land, sea, air (C-5 or C-17)

- High availability and low maintenance

- Automated health-checks

- Digital traceability and reporting

Benefits Statement:

The introduction of the Machina Labs Robotic Craftsman into DoD aviation depos will modernize the organic manufacturing capability thus significantly reduce production time and cost enabling maintainers to get critical assets back on the flight line on time and on budget. This cutting-edge manufacturing platform integrates artificial intelligence (AI) and robotics to produce unique, affordable, and hard-to-source parts with unmatched speed. Per CMTA 2024 report by RSO (AFLCMC-2024-0128), a deployed RoboCraftsman can generate savings of over $85m during its projected 25-year lifetime resulting in real ROI in Year 2.