Sharp Vision Software develops innovative solutions for training, engineering, manufacturing, maintenance, and field service using cutting-edge technologies to clients in defense, healthcare, pharmaceutical, aviation, power, and oil & gas industries with customers including U.S. Army, Navy and Air Force, Uniformed Services University, General Electric, Pfizer, ExxonMobil, Intel, and CAE.

Focus Area: Workforce Development/Visualization

Contact

Win Liu

win.liu@sharpvisionsoftware.com

443–527–7889

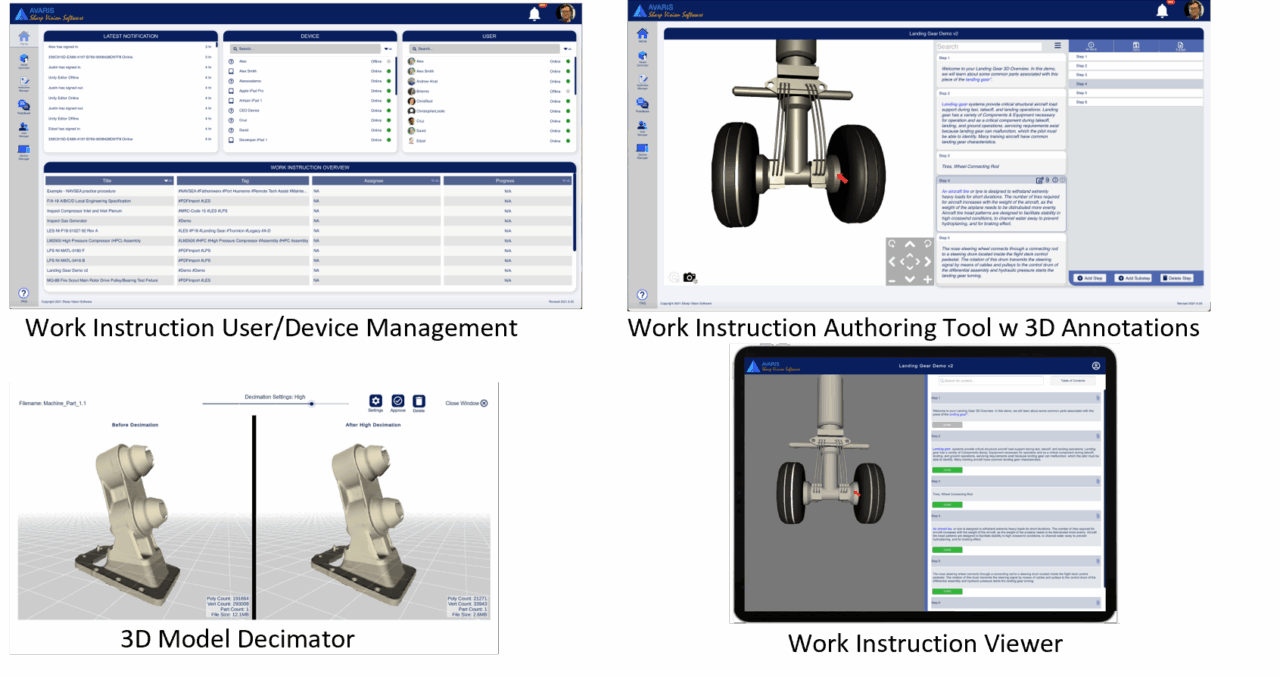

AI-Powered 3D Model-Based Work Instruction and Tech Manual Authoring/Viewing Tool for MRO

Problem Statement:

- Traditional technical documents that describe overhaul and repair processes for aircraft and aircraft components are limited in the ways technical information can be conveyed from engineers to artisans.

- Parts with complex features or many of a similar feature can be difficult to describe using conventional two-dimensional diagrams and/or images.

- The current procedure for revising technical documents is cumbersome and can often delay small, but important updates from being incorporated into new revisions quickly.

Benefits Statement:

- Utilization of 3D scanned and 3D modeled parts to further enhance ability to describe a part, feature, or process.

- More efficient knowledge transfer from engineer to artisan – less chance for artisan misunderstanding and error.

- Quick feedback/question tools for simple questions from artisans to engineers that prevents slow down of production.

- Visual-based training for new artisans, also helps to capture ‘tribal knowledge’ of experienced artisans .

- Easily convert existing ‘paper’ technical documents into digital work instructions.

- Quickly deployable to DoD sustainment sites for use in bulletins, AFCs, training-aids, and Maintenance, Repair, and Overhaul (MRO) type work operating integrated within PLM systems or as a standalone system.

Technology Solution Statement:

- Enhance existing technical document into a 3D model based digital work instruction format or draft completely new digital work instructions from the ground-up using AVARIS.

- Implement 3D scanned or 3D Computer Aided Design (CAD) models into work instruction steps to enhance understanding of complex parts and processes.

- Condenses 3D models, images, diagrams, data tables, and text information into an easy-to-navigate window that can easily be accessed by artisans on a tablet – which otherwise may be a 100+ page PDF.

- Utilizes rapidly growing network of digital content across the DoD to enhance work instruction understanding.