Focus Area: Advanced/Additive Manufacturing

Contact

Mike Simek

mike.simek@precisionadditive.com

317-319-3953

Precision Additive Solutions, Inc. is advancing the Laser Powder Bed Fusion (LPBF) ecosystem with the first platform engineered specifically for the safe, repeatable, and high-quality production of aerospace-grade parts at scale. Our system is built to process reactive alloys (magnesium, aluminum, titanium), non-reactive alloys (Inconel, copper), and refractory metals (tungsten, molybdenum, cobalt) with precision, consistency, and industrial throughput.

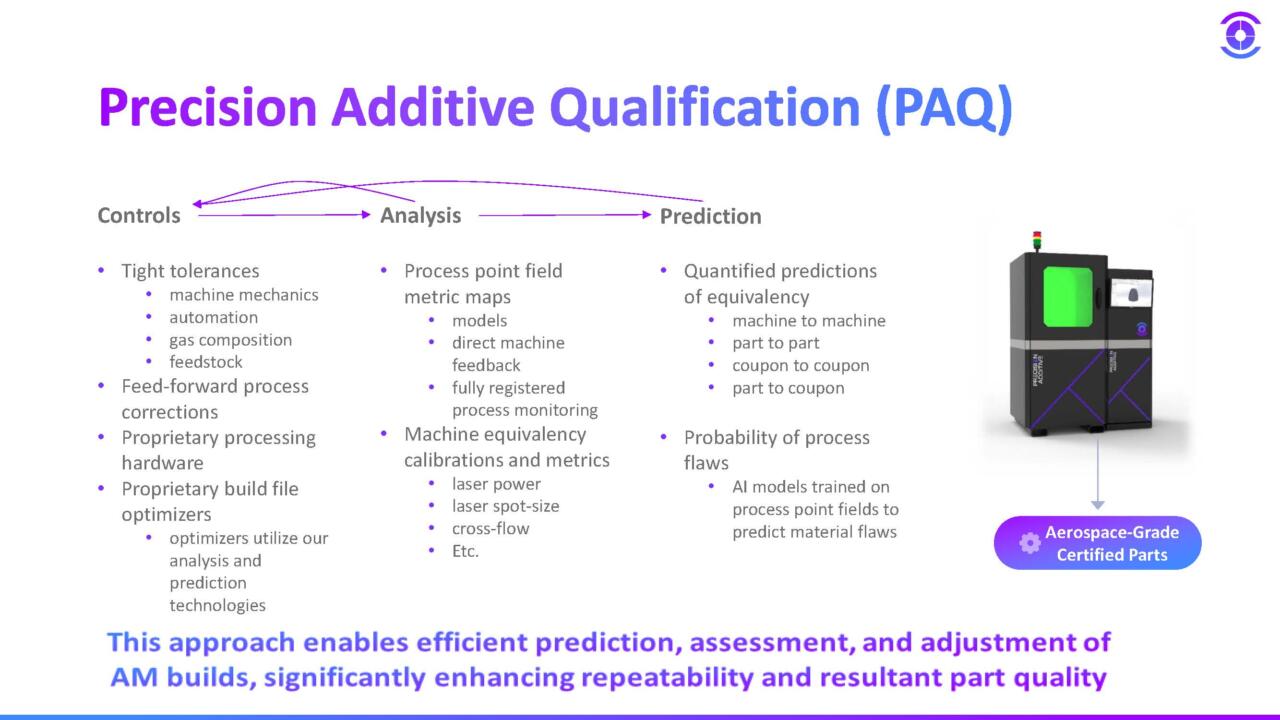

We integrate three core innovations that set us apart: Selective Stepped Laser Melting (SSLM™) – A proprietary process for adaptive melt control that enhances material integrity; Specialized Architecture for Reactive Material Handling – Enabling safe and efficient processing of challenging alloys; Precision Additive Qualification – A rigorous methodology that ensures repeatability and part certification for aerospace and defense.

3D+™ Hybrid Printing Technology

Problem Statement:

Aerospace and defense platforms depend on lightweight, high-performance materials, but the U.S. industrial base is no longer equipped to meet growing demand using traditional manufacturing methods. Today’s production landscape faces four critical barriers:

- Diminishing Domestic Manufacturing Sources

- Raw Material Shortages and Extended Lead Times

- Material and Process Complexity

- Limited Scalability

Technology Solution Statement:

Our 3D+™ hybrid printing technology (currently in development) sets us apart. This integrates reactive and refractory material processing, in-situ quality monitoring, real-time adaptive print parameter adjustment capability, in-process machining, small, medium, and large-scale Laser Powder Bed Fusion (up to 1.2m x 1.2m x 1.2m build volume), and a new, high-speed, extremely low spatter laser printing technology in Selective Stepped Laser Melting (SSLM™). SSLM™ provides position-by-position melt pool control through dynamically adjusted colinear beam parameters. It enables spatial variation in energy delivery, adaptive focus diameter control, and real-time thermal regulation. These capabilities predict and minimize porosity, suppress spatter, and allow for both high-fidelity feature resolution and high-rate deposition. This results in exceptionally high-quality finished parts, and a digital twin of the entire build process.

Benefits Statement:

Precision Additive addresses enabling true viability for alloys already in use, and pioneering pathways for materials previously inaccessible to additive manufacturing. We have developed a holistic qualification strategy that reduces reliance on coupon testing and instead emphasizes robust process controls, in-situ monitoring, and quality assurance integrated into the machine design. In practice, this approach means strengthening QMS certifications, ensuring regulatory compliance, establishing material traceability, machine-specific baselining, statistical process control, qualifying final part performance, and fortifying data management and cybersecurity.