Focus Area: Advanced/Additive Manufacturing

Contact

Josh Cooper

josh@cn-seamless.com

919-636-0380

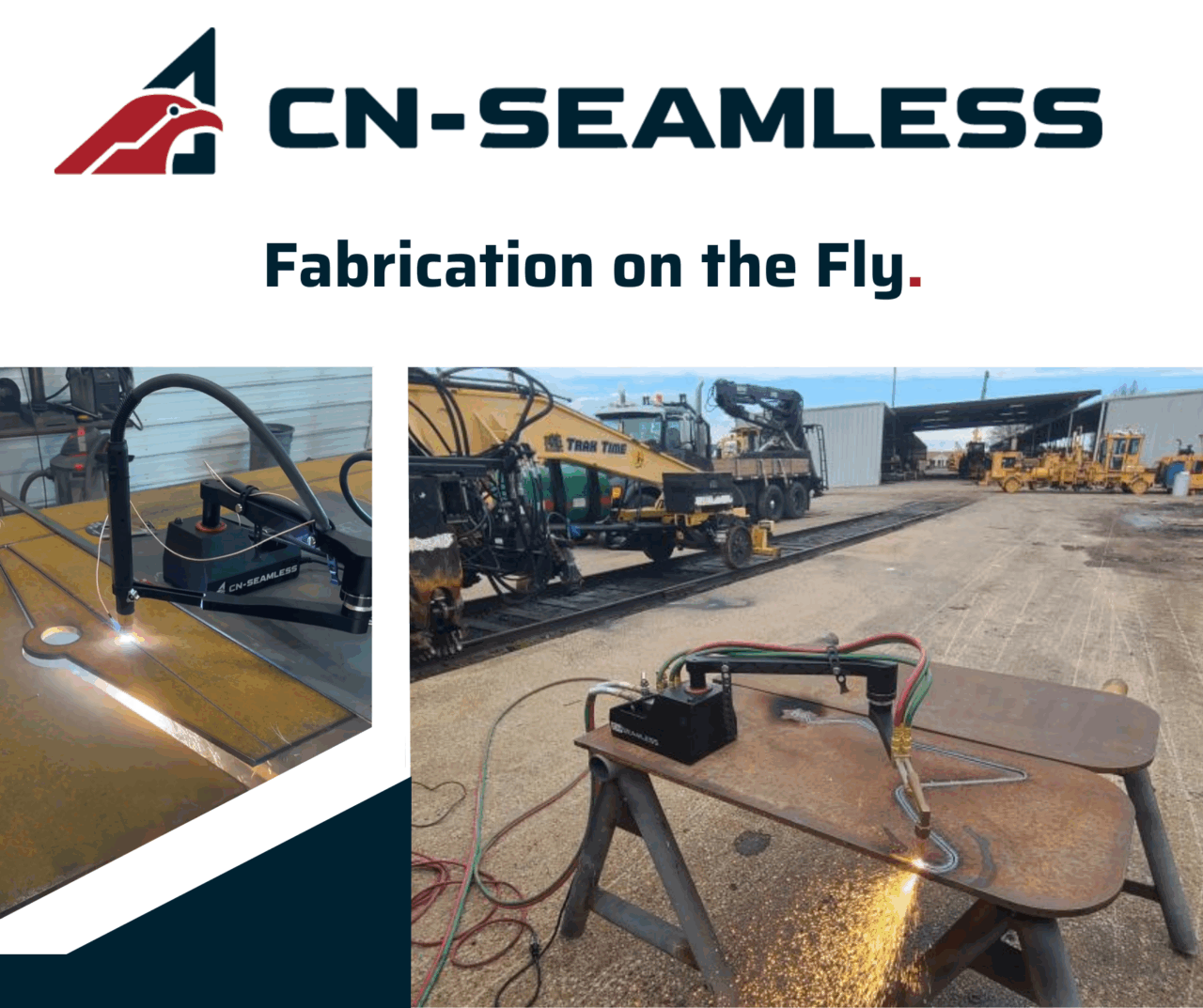

CN-Seamless is a North Carolina-founded technology company revolutionizing field fabrication and maintenance through compact, deployable automation systems. Our flagship product, the Mach 1, is a portable oxy-fuel and plasma cutting machine designed for use in austere environments by welders, maintainers, and fabricators. It enables precise metal cutting on flat plate, structural steel, and existing equipment—eliminating the need for stationary CNC infrastructure.

Deployable Automation System

Problem Statement:

The rapid maintenance and repair of large transportation assets, facilities, and operational support equipment is critical for mission readiness. Unlike commercial manufacturing, every repair within defense contexts is unique, reducing the benefit of automation compared to the time spent programming automated systems. Consequently, most maintenance still relies on the skill and availability of the maintainer. Unpredictable issues including battle damage, terrain hazards, mishaps, corrosion, or specialized mission demands force maintainers to spend time developing extensive maintenance projects, rely on depot repairs, or consider disposal.

Technology Solution Statement:

The Mach 1 is a portable, semi-automated fabrication platform that delivers powerful oxy-fuel and plasma cutting capabilities to any worksite, empowering maintainers, fabricators, and welders to perform precise cuts in metal with speed and consistency. Designed for rugged environments and rapid field deployment, the Mach 1 simplifies complex cutting tasks by automating manual processes typically reserved for heavy CNC equipment.

Currently under development, new end effectors for plasma blasting, welding, bevel cutting, 3D printing, and more will make the Mach 1 the ultimate automation system built for the field.

Benefits Statement:

The value of such a low-cost automation system that deploys directly to equipment and facilities being maintained is extremely high. The ability for any team in a base to perform rapid maintenance, fabrication, or repair with robotic precision specific to the tooling needed will drastically improve the decentralization of logistically complicated procedures. Gaining the ability to perform depot-level repairs on any base by bringing the Mach 1 to the equipment will result in millions of dollars saved in transportation costs alone. The portable nature of the Mach 1 means teams can become comfortable with the operation on base and have the ability to perform the same automated repairs while deployed. Furthermore, the end-effectors to be supported by the Mach 1 extend far beyond just maintenance use. Tactical breaching and rapid base construction and reconstruction are among the many additional potential benefits to having such a portable and easy to set up system.