Focus Area: Reliability Improvement (Hardware)

Contact

Dale Manning

dbmanning@partworks.com

571-302-2867

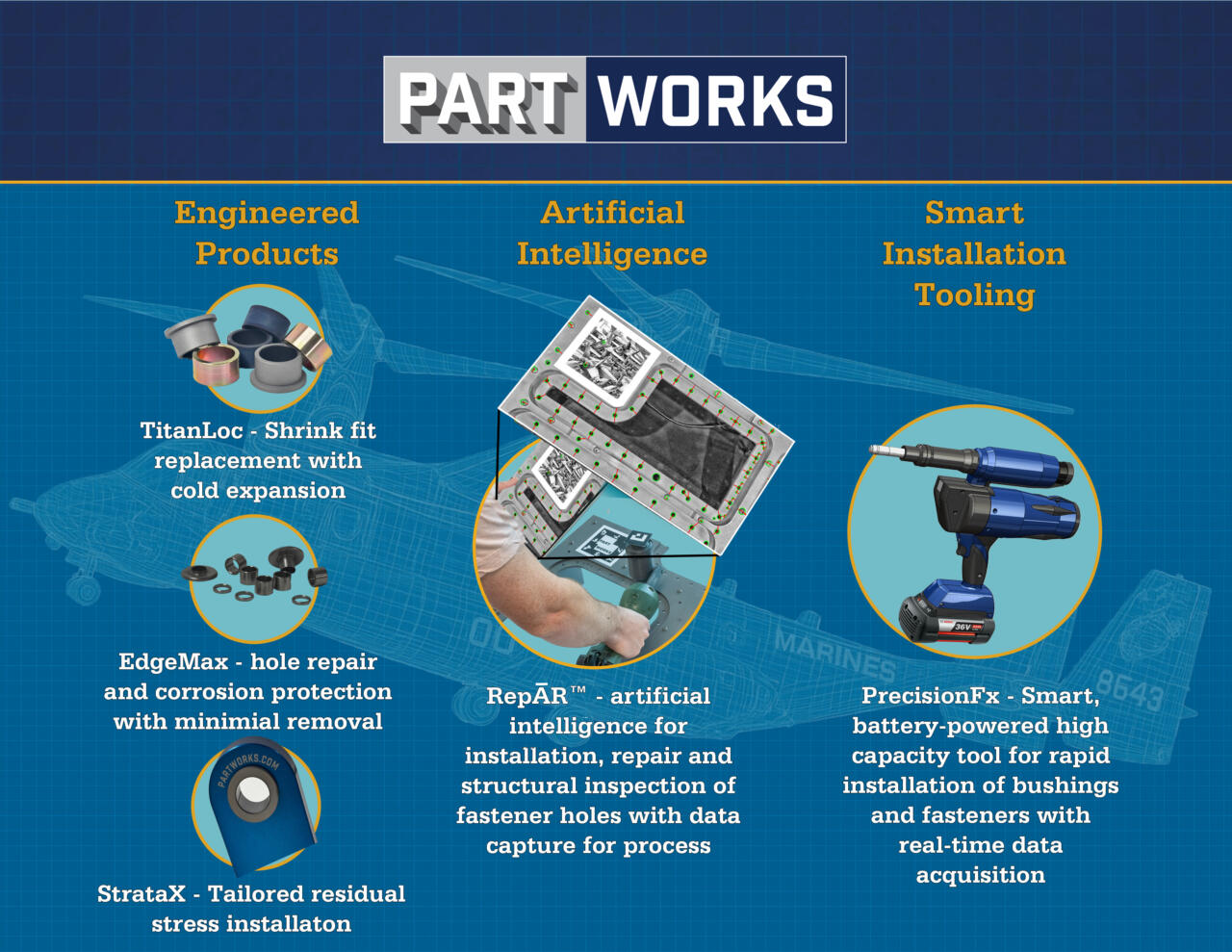

PartWorks LLC delivers field-deployable technologies for digital MRO, repair validation, and aircraft structural enhancement. Originally conceived to address the challenges of repairing structural fastener holes in hybrid materials subject to galvanic corrosion, our platform integrates point-of-action data acquisition, geometry capture, and component traceability to enable full repair lifecycle documentation and structural hole repair implementation.

The RepĀR™ system generates instantaneous local coordinate systems without external trackers, allowing fast, accurate capture of as-found geometry. The PrecisionFx tool supports high-force, high-speed bushing installation with real-time digital logging of critical process parameters—ensuring traceability and validation at the point of action. TitanLoc bushings emulate shrink-fit performance and have demonstrated superior average push-out resistance, improving long-term durability. StrataX bushings incorporate engineered residual stress profiles that mitigate crack growth and extend service life. EdgeMax repairs corroded or damaged fastener holes using geometry-preserving methods that maximize edge margin retention, enhancing structural reliability. These integrated solutions serve both defense and commercial aerospace customers who require fast, reliable, and digitally traceable repairs across global maintenance operations.

Field-deployable technologies for digital MRO, repair validation, and aircraft structural enhancement

Problem Statement:

- Geometry loss and overdrilling reduce edge margin during repairs

- Fatigue cracks and corrosion undermine structural joints

- Manual repair records lack consistency and retrievability

- Current tooling lacks integrated digital traceability

Technology Solution Statement:

- EdgeMax repairs corroded holes while preserving edge geometry

- StrataX mitigates fatigue with compressive stress-engineered bushings

- PrecisionFx enables real-time digital validation of installations

- TitanLoc enhances reliability with high push-out resistance

Benefits Statement:

- Maintains structural integrity by preserving original margins

- Reduces fatigue risk via engineered stress profiles

- Enables RCM through full-lifecycle repair traceability

- Improves repair speed, accuracy, and data quality

- Avoids need for stationary pumps and attached hydraulic hoses common to traditional high pull-force tools