Focus Area: Reliability Improvement (Hardware)

Contact

Josh Tyree

josh.tyree@gocrossflow.com

270-300-1716

Photon Flux LLC (Photon Flux), a Small Business (SB) Joint Venture (JV) formed pursuant to the Small Business Administration’s (SBA) Mentor-Protégé Program, consists of member companies Torch Technologies, Inc. (Torch; Mentor) and Crossflow Technologies, Inc. (Crossflow; Protégé). As a Mentor-Protégé JV, Photon Flux formally maintains SB status while inheriting the Past Performance and capabilities of both member companies. We have extensive prototype development capabilities, modeling and simulation (M&S) tools, laboratories, and over 85,000 square feet of design, development, and integration space within the Torch Technology Integration & Prototyping Center (TIPC) located in Huntsville, Alabama. As a developer of prototypes, JV-members Torch and Crossflow are capable and experienced in the preparation of test plans for physical and virtual experiments and performing risk analysis, as well as implementing risk abatement activities. Photon Flux can perform operations and maintenance enhancements, field trials, and support the design and construction of upgraded/new equipment, Test Program Set (TPS) development, and root cause analysis of equipment failures. Photon Flux has AS9100RevD-certified contractor-site facilities to support material fabrication and technical support. JV-member Torch has invested millions of dollars in laboratory facilities and equipment to support rapid prototyping, re-engineering, and engineering sustainment activities.

IVHMS Data Collection Box (DCB)

Problem Statement:

Aircraft/Aircraft Support Equipment DMSMS/Obsolescence

Technology Solution Statement:

Reverse Engineering, and Rapid Prototyping

Benefits Statement:

Data Collection, Reverse Engineering, and Digital Engineering

- The DCB was utilized at Nellis AFB to capture data on 11 runs from 3 different HH-60Gs.

- From the information collected by the DCB and associated software, we successfully reverse engineered unknowns about the communication structure and developed functional tests.

- This data capture allows us to know how the LRUs behave in real service as well as what each LRU communication is required during this power on event.

- This data capture was used to build Test Requirements Documents (TRDs) and Technical Data Packages (TDPs) to lay the groundwork for Air Force Depot Level Repair (DLR).

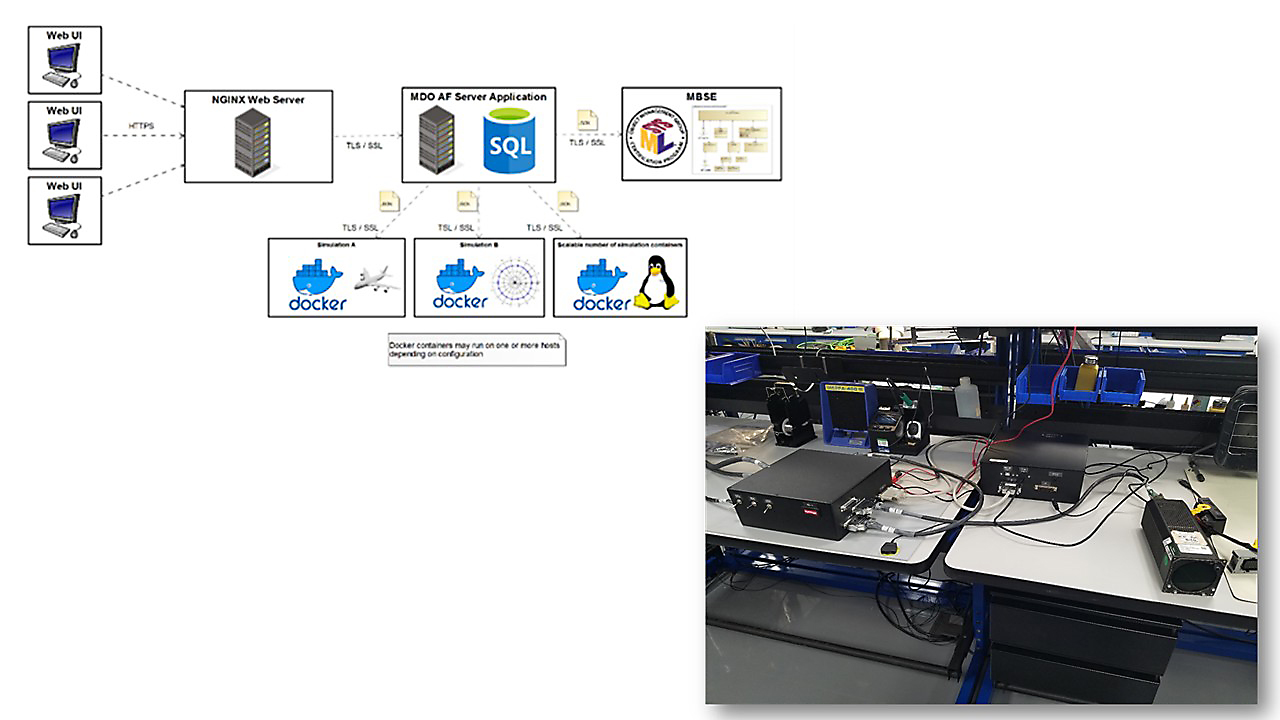

- Additionally, Photon Flux’s Multi Domain Operations Analysis Framework (MDO AF) provides a federated System and Systems of Systems representation in a distributed computational environment, thus providing a digital representation of a system of interest.