Technology Title

Accio3D – Agentic AI for Maintenance, Repair & Sustainment

Tech Focus Area

Additive Manufacturing

Abstract

Problem Statement: The Department of Defense (DoD) faces escalating challenges in maintenance and sustainment due to part obsolescence, extended lead times, and fragile supply chains. Systems lasting 20–30 years often rely on components obsolete in 4–5. This mismatch forces lifetime buys, costly warehousing, emergency sourcing, and mission delays. A single obsolete part can cost millions in procurement and logistics, driving up sustainment costs and eroding readiness.

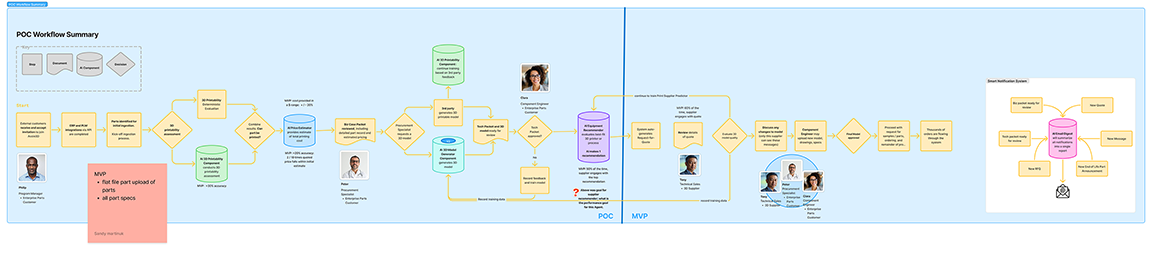

Innovation Solution: Accio3D delivers an AI-powered additive manufacturing platform purpose-built to solve the end-of-life parts problem. Its ecosystem of specialized AI agents automates more than 80% of sourcing and qualification workflows:

- Printability Agents evaluate whether parts can be 3D printed.

- Materials & Equipment Agents match components with certified materials and MIL-STD equipment.

- Sourcing & Ordering Agents connect buyers with ITAR-compliant vendors across the Defense Industrial Base.

- Qualification & ROI Agents assess mission requirements, cost tradeoffs, and recommend qualification levels.

- Logistics & Payment Agents consolidate orders, manage suppliers, and enable secure transactions.

The result: static inventory becomes digital inventory—parts printable on demand, anywhere in the world.

Benefits to the DoD:

- Accelerated Readiness: Lead times shrink from months to days with point-of-need printing.

- Cost Efficiency: Eliminates lifetime buys, warehousing, and global shipping.

- Operational Resilience: Adds redundancy while protecting IP and digital thread integrity.

- Sustainability: Reduces waste from over-ordering and scrapped parts.

- Workforce Enablement: Serves as a co-pilot for engineers, reducing workload pressures.

Innovation Challenges: Adopting AI-enabled additive manufacturing requires addressing:

- Cybersecurity and IP protection for sensitive defense data.

- Integration with legacy PLM/ERP systems.

- Trust and qualification standards under MIL-SPEC.

Accio3D is tackling these through secure Azure-based deployment, ITAR/DFARS compliance, and close collaboration with DoD advisors and industry experts.

Technical Maturity / Demonstration Results: Accio3D has developed a working architecture with an Azure-orchestrated agentic AI framework. MVP delivery is planned for late 2025, with demonstrations underway with aerospace and defense partners. Early testing confirms the platform automates most workflows, identifies viable 3D-printable parts, and connects with qualified suppliers in real time. This mission-ready capability directly addresses the DoD's sustainment gap with on-demand, cost-effective part replacement.