Technology Title

Supply Chain Independent SolidStir® Repairing Technology

Tech Focus Area

Additive Manufacturing

Abstract

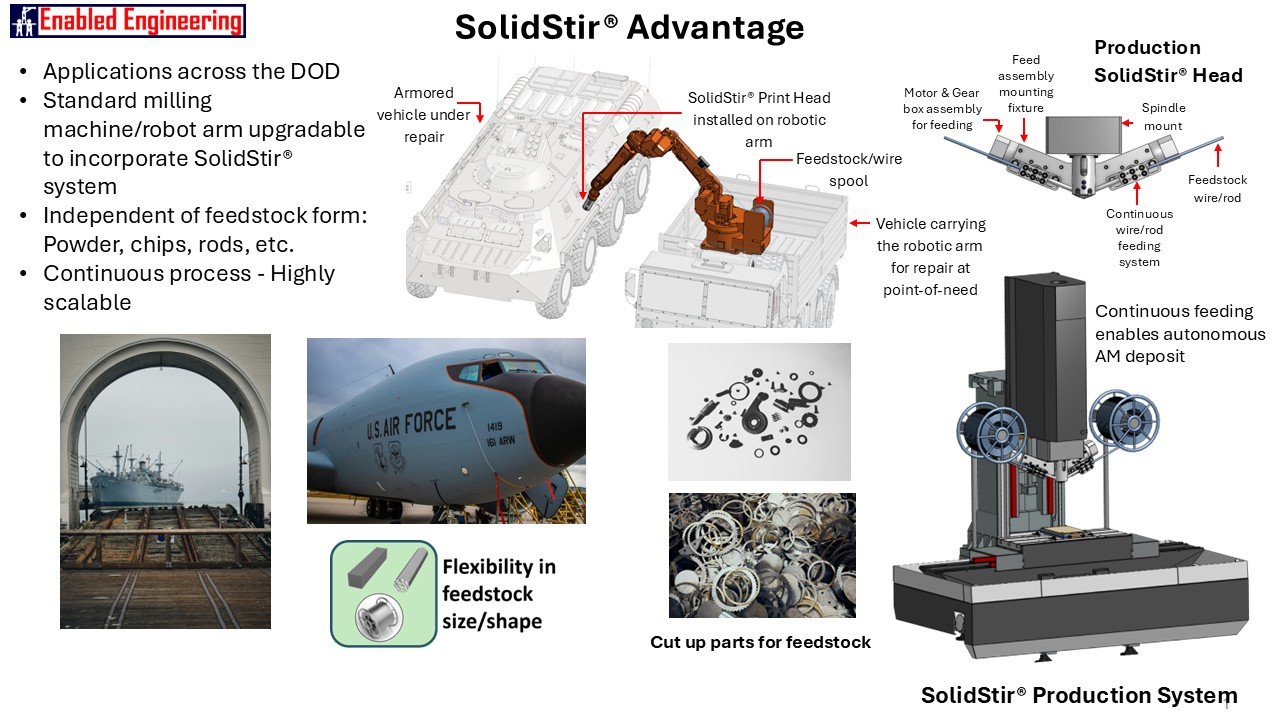

Problem Statement: Expeditionary vehicle and equipment repair is hampered by the availability of appropriate feedstock in the field (such as remote locations, at sea, or on aircraft). In addition, standard manufacturing equipment used for machining is not suitable for repairing components with filler metal addition.

Description of the Innovation Solution: Enabled Engineering has created a breakthrough solution with its patented SolidStir® technology, addressing key gaps in metal additive manufacturing (AM) and repair. SolidStir® is a next-generation, solid-state AM and metal extrusion platform that builds on the principles of friction stir welding and processing, delivering high-performance and sustainable manufacturing capabilities. Enabled Engineering delivers high-performance, scalable solutions for the defense, aerospace, automotive, and energy sectors. The parts produced with this technology are composed of fully dense, consolidated deposits using AM. The parts have superior interlayer bonding with wrought metal microstructures and properties.

Enabled Engineering’s systems can be mounted on any existing computer numerical control (CNC) machine and located on the back of a vehicle or the deck of a ship or in an airplane hold. It can even be miniaturized to mount on industrial robots for solid-state repair applications. Not only can this system be used for manufacturing new components, one can do so by cutting up broken or worn-out parts as feedstock and recycling them into new parts or extruding them into various profiles, rods and wires. Wires and rods can be used for welding and conventional additive processes as feedstock. The feedstock size and shape are flexible in SolidStir® technologies. It is simply cut to fit into the feed chambers, and the feeding system will handle these irregular pieces. In addition, the system can be set up for continuous feeding. In using this SolidStir® technique, the resultant parts have the same or improved material properties when compared to the original parts due to dynamically recrystallized microstructure. The system is designed for high build rates using lubricant-free manufacturing.

Scaling the system down in size is one challenge while having it large enough to accept reasonably sized cut-up parts, which can be turned into new high-quality replacements. Enabled Engineering can make these trades and develop a robust system capable of supporting the DOD in challenging locations. Another critical objective is simplifying the system for ease of set-up, use, and repair in the field.

Technical Maturity / Demonstration Results: Enabled Engineering has demonstrated using cut-up aluminum parts through our research and development system, resulting in manufactured components as shown in our video for this challenge. The technology is at a MRL of 7 for a range of aluminum alloys. It is ready to demonstrate in the field. For future applications, our researchers have experimented with magnesium, copper and titanium with limited success thus far.

Graphic