Technology Title

XTRU – Digital Thread Manufacturing

Tech Focus Area

Business Processes/Partnerships

Abstract

Structural spare part production for airframes requires significant skill and time for designing, manufacturing, and proving out the dies, fixtures and joggle blocks required by traditional presses and mills to manufacture these components. This limits production to the same location of the large machines and tools, leaving high value warfighter assets rendered mission incapable for months to years, diminishing warfighter readiness.

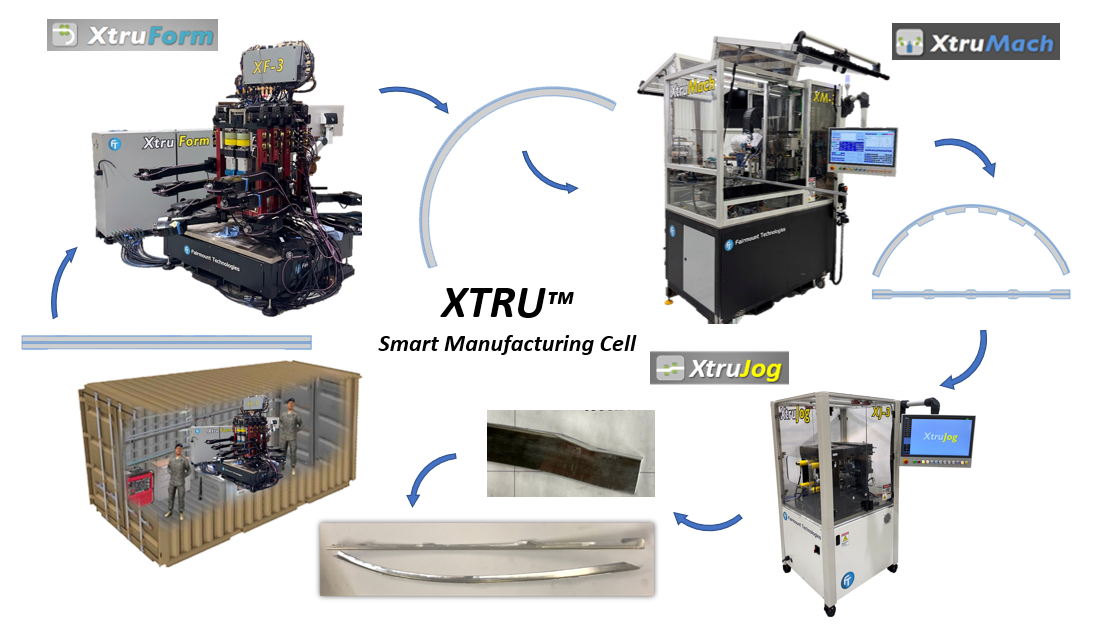

The solution is XTRU, a native digital suite of three portable tooling-free CNC machines, XtruForm (XF), XtruMach (XM), and XtruJog (XJ), that implement traditional extrusion forming, machining, and joggling processes for producing spares without tooling, using CNC programs. Starting with the drawing-specified extrusion XTRU produces flight critical structural parts that meet all requirements, including airworthiness. Digital TDPs and avoidance of tooling enables rapid production of spares where needed for repairs.

Starting with a CAD model of a part, a technical data package (TDP) for manufacturing typical parts can be developed in a few hours to 1 day if the manufacturing technical data package (TDP) is available, and a week to a few weeks for complex parts needing a TDP, custom soft jaws, thinning of extrusion, etc. Once the TDP has been developed for a part, it can be used to reproduce the part anywhere the machines and material are available. XTRU produces high accuracy components, while saving cost and lead time of tool development, NRE, setup and tool maintenance.

With digital CNC programs replacing tooling and containerized portable small footprint machines capable of producing unlimited length parts because they flow through the machines, XTRU enables forward-deployed sustainment capabilities. Depots and operational bases can access a shared database of TDPs to produce components on demand, simplifying supply chain logistics. Wide adoption of XTRU will lower the cost base of spares and increase asset availability.

One challenge will be the compatibility of communication in transferring data to remote locations. We will work closely with users upfront to understand programs like Athena and the development that may be required to ensure our processes support that network. Some modifications to our utilities and or hardware may be required to support self-contained operation. A container with doors along the side will allow longer length components to flow through while being manufactured. We will validate each of the technologies in a containerized setting to ensure smooth fielding.

XTRU has been demonstrated to the depots and ABDR units and is in the process of being acquired by WR-ALC. Thousands of formed, milled and joggled components have been sold to DLA Aviation as well as commercial OEMs. Active projects are being worked with all three branches to expand the capabilities of the suite. XTRU promises to impact many aspects of aircraft sustainment and increase warfighter readiness.

Graphic