Technology Title

COPA 500: Intelligent Industrial Automation Control for Maintenance Operations

Tech Focus Area

Reliability Improvement

Abstract

Problem: Across the DoW, the infrastructure that runs maintenance bays and depots is running on industrial control systems that are 20-30 years old. These systems were never designed for modern cybersecurity, remote access, or scalable automation. Updates, patches, and configuration changes often require on-site technicians using vendor-locked tools, driving up maintenance costs and extending downtime. These systems are inefficient in their amount of unscheduled downtime and dangerously insecure against Russian or Chinese cyber-attacks, which often target supply chain infrastructure.

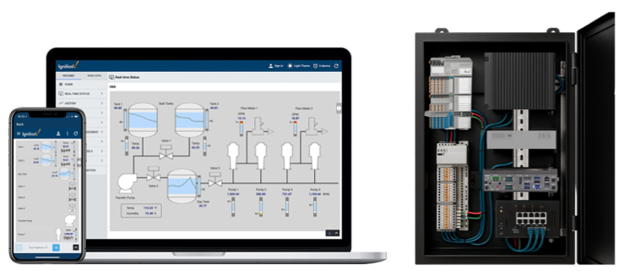

Description of the Innovation Solution: The team at CPLANE.ai has built COPA 500, an industrial control system built to increase uptime and eliminate vendor lock-in, with built-in cybersecurity for zero trust environments. It combines open, modular hardware with a tightly integrated, proprietary software stack that allows for centralized control, remote management, and resilient operations. COPA 500 can maintain industrial operations during device failure and system maintenance. CPLANE.ai has a provisional patent in progress for the orchestration and management of multi-vendor control systems, which allow maintenance bays and depots to be upgraded with hardware from any manufacturer that complies with the industry-created Open Process Automation Standard, as often as needed.

Benefits to the DoW: COPA 500 eliminates the need for legacy hardware and by running all control logic and security in a containerized environment orchestrated across modular hardware. It provides maintainers the ability to securely monitor, diagnose, and update remotely or from a central location. COPA 500’s open architecture typically costs 50% less compared to proprietary options. Remote access, affordability, and cybersecurity provides a path for users to deploy, operate, and maintain advanced maintenance systems that meet modern security and operational needs.

Innovation Challenges: Our primary risk is integration. Many industrial sites have non-standardized or legacy equipment and unique configurations that can make system integration challenging. To mitigate this risk, COPA 500 is designed with modularity in mind. It can be deployed in phases, connected to existing hardware and tailored to specific infrastructure types using interoperable, standards-based components like CODESYS and Ignition.

Technical Maturity/Demonstration Results: COPA 500 is currently at TRL 6. CPLANE.ai has secured multiple paying customers across the energy and industrial sectors who are actively deploying or testing the COPA 500 platform. ExxonMobil is the largest customer to date, with COPA 500 systems in use at their large chemical terminal in Louisiana. Other major clients include BP, Equinor, Petrobras, and Trailblazer Critical Minerals, each of whom has invested in the COPA QuickStart program that evaluates the platform’s capabilities in operational environments.

Graphic