Technology Title

Automated Wire Test Set (AWTS): Transforming F-16 Electrical Maintenance and Sustainment

Tech Focus Area

Reliability Improvement

Abstract

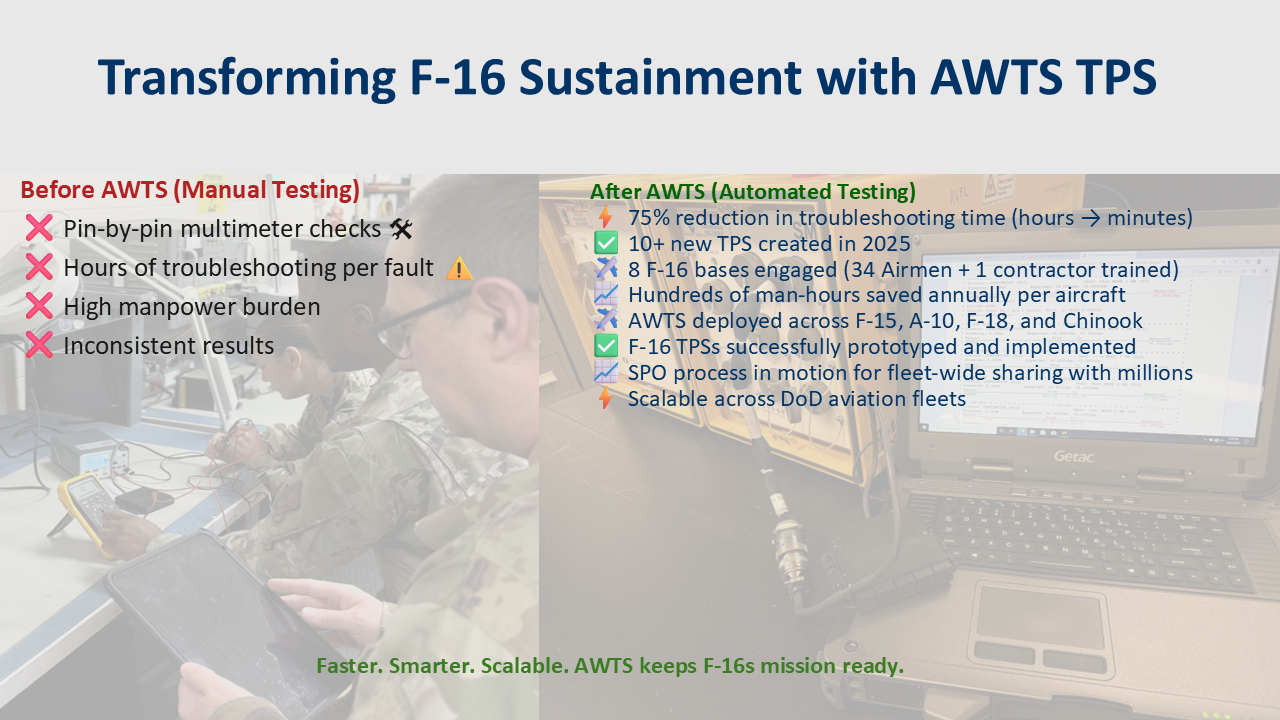

Modern F-16 electrical troubleshooting relies on slow, pin-by-pin multimeter checks of wiring harnesses and avionics components. These manual processes are labor-intensive, error-prone, and cause excessive aircraft downtime. Fault isolation can take hours, wasting man-hours and sortie generation time. This inefficiency increases sustainment costs, reduces readiness, and impacts all F-16 units worldwide.

The Automated Wire Test Set (AWTS) is a software-programmable, automated platform that modernizes F-16 electrical troubleshooting. Instead of hours of manual testing, AWTS uses Test Program Sets (TPSs) to perform resistance, capacitance, and voltage checks in minutes. It delivers fast, accurate fault isolation and allows less-experienced maintainers to complete advanced diagnostics through standardized procedures. AWTS reduces troubleshooting time, cuts costs, and boosts mission readiness.

In August 2025, eight F-16 Airmen developed five TPSs for critical systems—the Pilot Stick Grip, T-Grip, 5-Mod Panel, IFF Control Panel, and Miscellaneous Panel. The T-Grip TPS was validated the same day on a faulty unit, showing immediate value. This effort is projected to save hundreds of man-hours annually and has already expanded across Holloman, Andrews, Aviano, Toledo, Nellis, Fort Wayne, and Atlantic City, producing over ten TPSs.

Key contributors include Dr. Robert Norcross II (Langley-Eustis VA), MSGT David Williams (Robins AFB GA), SSGT Raelynn Navarro (Toledo ANGB OH), TSGT Matthew Crawford (Toledo ANGB OH), SSGT Peter Daigle (Andrews AFB), TSGT Nizam Khan (Holloman AFB), TSGT Denzel Ramdhanie (Holloman AFB), TSGT Tyler Bevard (Andrews AFB), TSGT Alex Mix (Ft Wayne ANGB IN), and SMSGT Jeremy Bender (Ft Wayne ANGB IN).

Benefits to the DoD

- 75% reduction in troubleshooting time—hours to minutes.

- Saves dozens of man-hours per aircraft annually.

- Improves safety, reliability, and readiness.

- Reduces dependence on experts and extends legacy part life.

- Allows less-proficient technicians to test components using standardized steps.

- Scalable and reproducible: 34 trained Airmen with SPO support expanding TPS development enterprise wide.

Challenges of Innovation

- Code validation requires coordination between maintainers and engineers, mitigated through peer review, shared code libraries, and contractor support.

- Connector shortages addressed via standardized sourcing databases and base collaboration.

Technical Maturity / Demonstration Results

- AWTS operates across F-15, A-10, F-18, and Chinook platforms.

- F-16 TPSs prototyped, demonstrated, and implemented at eight Air Bases.

- F-16 SPO developing TPS approval and sharing process with millions funded for expansion.

This Airmen-led innovation, the F-16 community’s largest TPS initiative; enhances sustainment by improving diagnostics, reducing costs, and increasing readiness. It fully supports the MIC mission to make sustainment more agile, effective, and affordable.

Graphic