Technology Title

Satori XR – AI-Powered Augmented Reality Knowledge Base for Military Efficiency

Tech Focus Area

Enhanced Inspection

Abstract

Defense assets are becoming increasingly sophisticated. Traditional maintenance tools like 2D manuals, static diagrams, and lengthy training programs fail to keep pace with system complexity and evolving configurations. These legacy approaches lead to longer maintenance cycles, higher costs, reduced operational readiness and may lead to high-impact critical errors.

Our product provides the DoD a secure, intelligent, and field-deployable solution to digitize maintenance expertise, ensure repeatability, and accelerate decision-making across platforms. Satori XR’s Augmented Reality (AR) Guidance System acts as a real-time, visual co-pilot, guiding technicians through step-by-step inspection workflows using AR overlays projected on the physical asset thus improving understanding, decision-making, and procedural accuracy without any physical disassembly.

Our vision modules automatically detect components, verify presence and condition, and read serial numbers via OCR—even on curved, low-contrast, or partially obscured surfaces. Each action, image, and annotation is captured into a living knowledge base that links to maintenance history and supports predictive analytics. The interface adapts dynamically to user behavior, providing just-in-time visual cues to disseminate information.

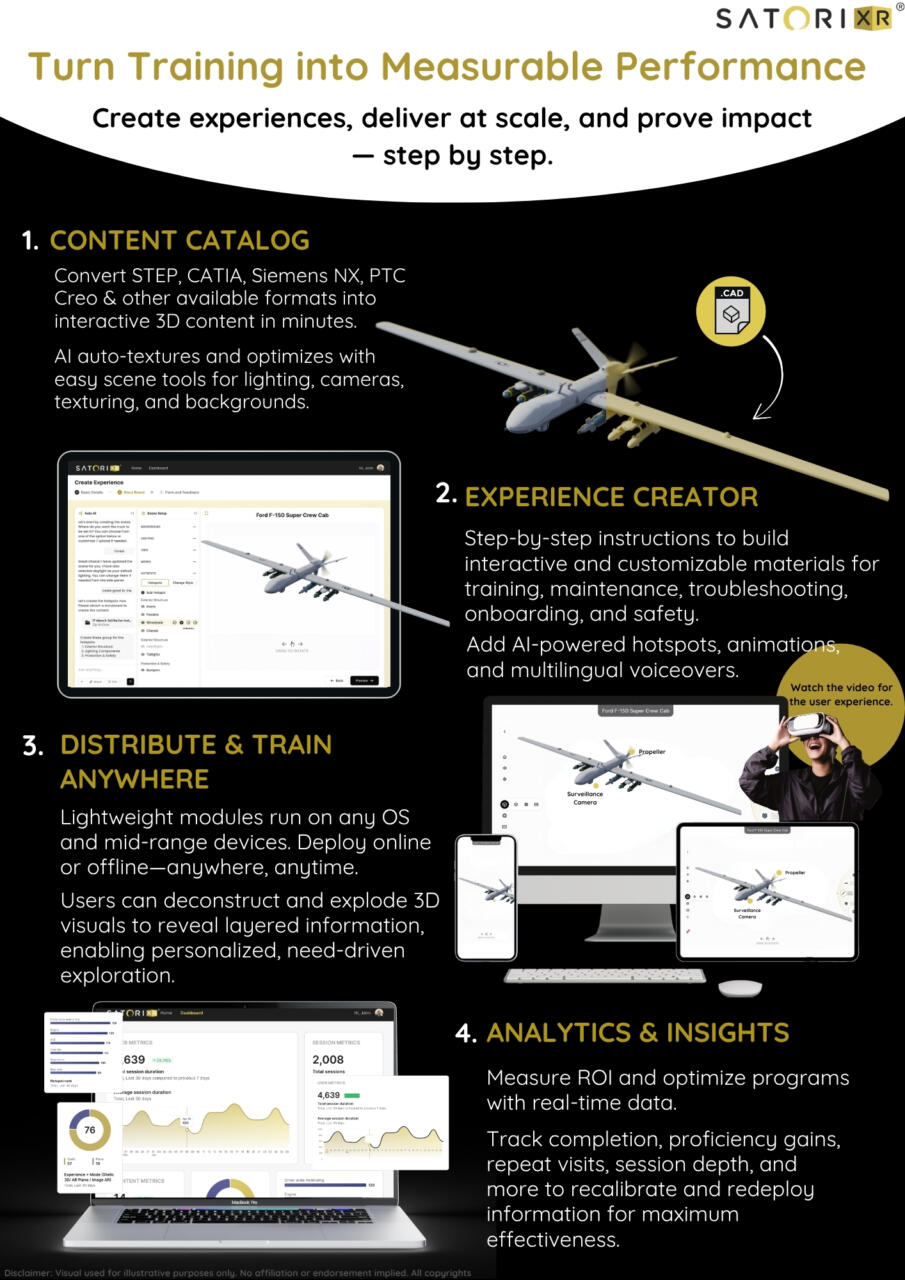

Designed for secure deployment on DoD-approved on-premises or edge environments, it integrates with existing Engineering systems/PLM/ERP/CMMS/LMS, etc. to pull content from or to push content into. Satori XRs easy 4-step process (documented on the video) is as follows:

- Load your complex design files, brochures or specs into the application – Satori’s “no technical expertise” required AI engine identifies and generates the 3D asset.

- Jump-start the “experience” creation with customizable workflows. Set-up “Hotspots” with voiceovers, animations, multilingual narration and descriptions

- Distribute the content with secure access control using iOS, Android, PC, Web, VR headsets

- React, Refine and Re-deploy using real-time analytics.

Key Benefits to the DOD are:

- Increased readiness: Reduces inspection time by 40%, improving asset availability.

- Error-proof operations: Enforces standardization and minimizes human error.

- Knowledge capture: Preserves expert insights through guided AR workflows.

- Data auditability: Creates a visual digital thread of every inspection for performance tracking and a continuous feedback loop for optimization.

- Scalability: Configurable for air, land or naval systems with the same process.

Satori XR aligns with the defense sector’s push toward digital transformation, and predictive maintenance. The system has been validated in aerospace engine inspection trials to achieve >95% accuracy in component detection, >90% OCR success for serial number recognition and 30–40% reduction in inspection cycle time. In an environment where readiness and precision are mission-critical, Satori XR transforms complexity into clarity —anywhere, anytime.

Graphic