Technology Title

FLX BOT: Rapid Field-Deployable Robotic System for Confined Space Inspection, Diagnostics, and Repair

Tech Focus Area

Enhanced Inspection

Abstract

Problem Statement: Maintainers across the DoD face recurring challenges when inspecting/repairing confined and hazardous spaces such as aircraft fuel tanks, ground vehicle engine compartments, and shipboard structures. These often require confined-space entry, teardowns, or reliance on specialized teams, which increase cycle time, risk, and reduce readiness. At the tactical edge, these delays can interfere with strategic tempo or force equipment abandonment. At depots, they contribute to growing inspection backlogs and parts procurement delays, further impacting fleet availability.

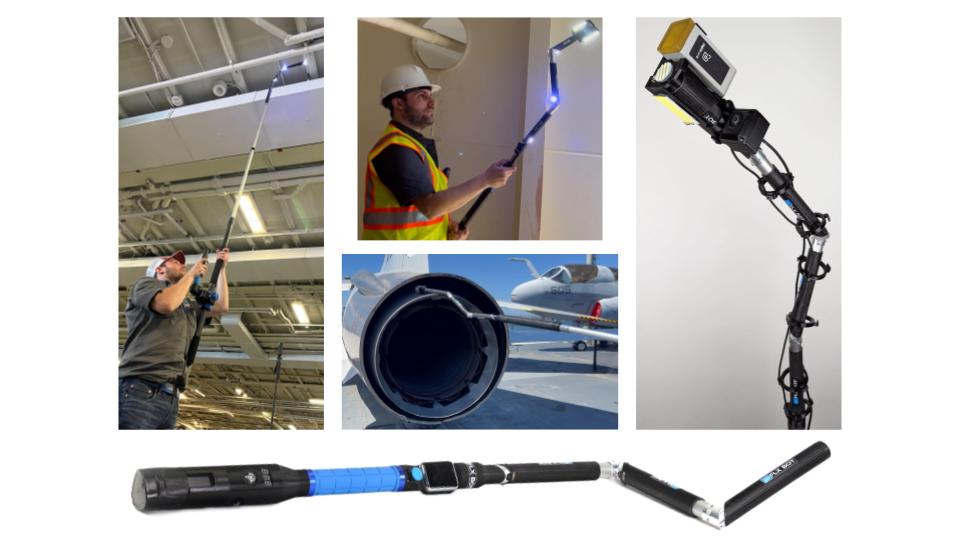

Solution: FLX BOT is a handheld robot designed for rapid deployment by operators in the field. It delivers “snake-like” maneuverability through modular links that articulate with 360° rotation and linear extension. At 1” in diameter, it can access tight spaces to perform non-destructive inspections (NDI) and maintenance without confined-space entry or teardowns. Its patented modular design allows rapid reconfiguration in length and function, while swappable end effectors (including cameras, sensors, and applicators) enable users to both detect faults and act in real time. Operated via handheld control or extension pole, the system requires minimal training and integrates into existing tool kits.

Benefits: Results in Navy pilots include 90% reductions in inspection times vs. current MRC methods, and successful corrosion mapping in hard-to-reach locations. FLX BOT units deployed at Ingalls Shipbuilding saved significant time/costs multiple times a month vs. traditional methods to answer mission critical questions in hard-to-access areas. In the first day of deployment alone, the FLX BOT saved multiple days of scaffolding moving/setup by answering a critical inspection question. During Navy Battlefield Damage Assessment exercises, FLX BOT was able to inspect where other tech could not, ensuring more rapid diagnoses during high pressure situations. During a transit pilot, the robot increased worker efficiency by 150% during a station inspection.

Challenges: Key challenges include scaling manufacturing for lower-cost procurement, integrating AI-enabled condition-based maintenance, meeting operation requirements for explosion-proof environments and ability to be submerged. Ongoing pilots are addressing integration with platforms and data-sharing to ensure smooth transition into existing maintenance ecosystems.

Maturity: FLX BOT is at TRL 6, with evaluation units deployed in paid pilots with the Navy and Air Force. Three systems are deployed with Ingalls Shipbuilding to improve QA efforts while lowering costs and increasing worker safety and productivity. Patents in place protect the architecture, securing FLX BOT’s unique combination of precision, compact form factor, and dexterity. The system is available today for demos, with a clear roadmap to TRL 9 through current partnerships.

Graphic