Technology Title

Smart Autonomous Robots for MRO Finishing, Coating and Welding Operations

Tech Focus Area

Coatings/Corrosion Prevention

Abstract

Traditionally, robotics solutions in maintenance and sustainment activities have been inflexible and expensive, requiring significant upfront costs along with manual programming for every setup and part. As a result, robotics usage in high-mix sustainment operations have been severely limited due to setup complexity and processing inflexibility. Despite necessary and critical investments for fleet sustainment and readiness, increases in the cost-per-flight-hour metric in recent years have raised concerns, with a 20% jump between FY21 and FY23. Additionally, maintenance bottlenecks contribute to grounded aircraft and assets that are not available to the warfighter and mission capability.

Cohesive Robotics delivers smarter robots for high-mix manufacturing and maintenance across diverse industries. Our core solution is Argus OS™, a proprietary, AI-enabled software stack that eliminates complex, time-consuming programming and integration for easier automation. Its flexibility supports a wide range of applications and OEM hardware, ideal for high-mix production requiring part variation and workflow flexibility.

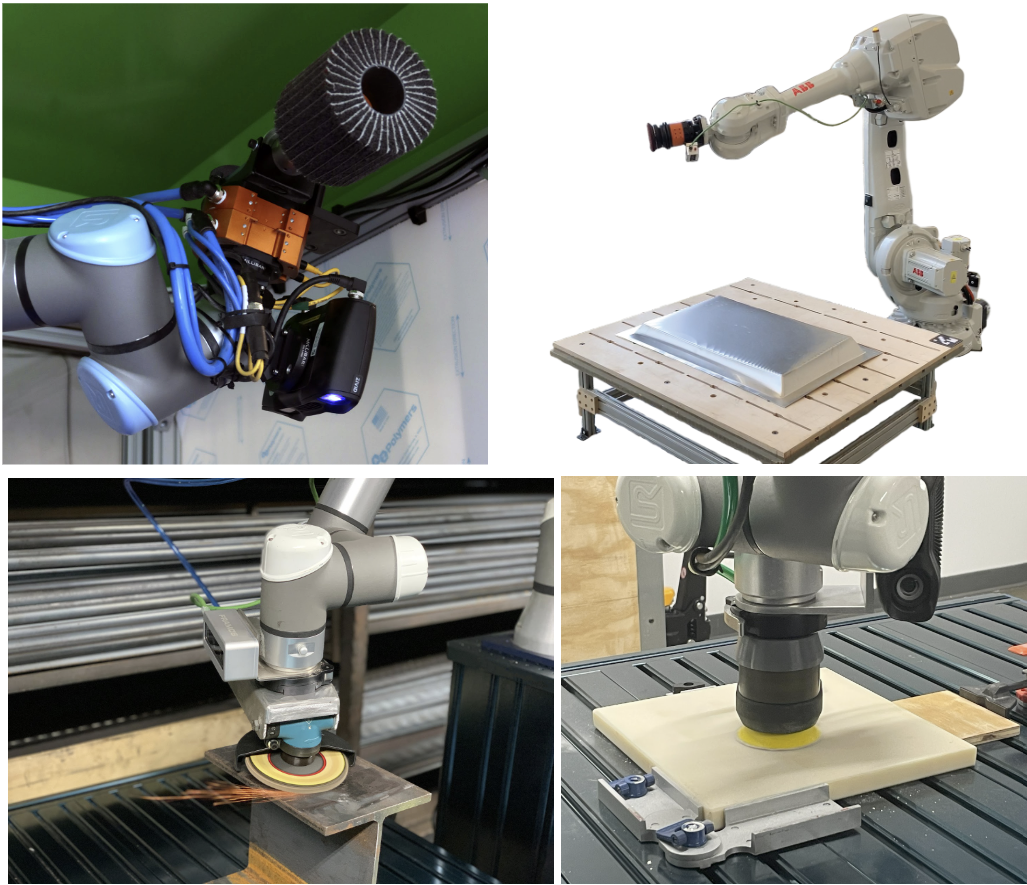

Argus OS™ provides a truly autonomous, no-code, and no-teach experience, featuring:

- Support for topology-based applications (e.g., sanding, coating, welding, polishing).

- 3D vision-based AI part scanning and registration (with or without CAD data).

- On-the-fly, collision-free robot programming and motion planning for most robot OEMs.

- Key benefits for DOD mission needs include:

- Increased Productivity: Boosts production by 30% or more.

- Consistent Quality: Reduces rework/scrap rates by 80% or more through precision and consistency.

- Enhanced Safety: Automates dangerous tasks, reducing accidents.

- Greater Flexibility: The same workcell can adapt to perform multiple tasks (e.g., weld, grind, and polish a part).

Cohesive Robotics began internal research and development of Argus OS™ in 2022 and released its first complete turnkey robotic workcell powered by the software in early 2024. Sold directly to manufacturers across industries, the Smart Finishing Robotic Workcell supports a wide variety of material removal and surface finishing processes. The first production system is deployed to a commercial customer site in New York, increasing production throughput an average of 50% while protecting workers from hazardous metal dust and ergonomic tool vibration exposure. In July 2025, the Smart Welding Robotic Workcell was released, supporting a variety of welding processes in high-mix environments. The first production version of the system is configured for TIG welding. It was installed at a New York manufacturer in August and entered production usage in September, generating throughput improvements of 60% with further increases expected as the system is automatically optimized. A second system will be installed in late Q4 at a medical technology manufacturer in New Jersey.

Graphic