Technology Title

Expeditionary Cold Spray

Tech Focus Area

Coatings/Corrosion Prevention

Abstract

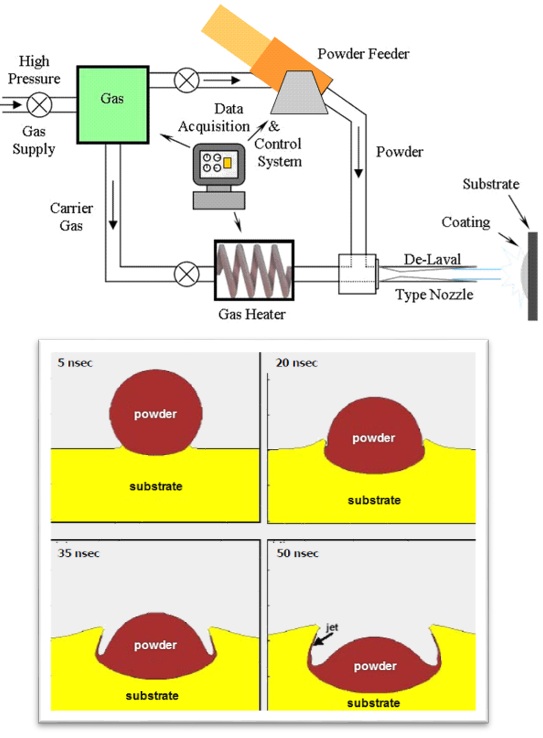

The U.S. Navy faces growing challenges in maintaining critical ship and submarine assets due to high operational tempo and an aging industrial base. Traditional repair methods such as welding, electroplating, and epoxy-based systems introduce risks like heat-induced warpage, poor adhesion, and prolonged dry dock periods. Cold spray technology offers a low temperature, solid state additive repair process using supersonic particles of metal which bond to substrates without melting. This enables dimensional restoration of components with minimal heat input, preserving base material properties while reducing repair time and cost.

Cold spray has rapidly transitioned from lab-scale development to active field deployment. Since 2020, NAVSEA has established multiple cold spray repair cells across the fleet, enabling expeditionary repairs to shipboard components. This technology has been used successfully aboard submarines and surface ships, demonstrating its readiness and versatility in real-world conditions.

One breakthrough repair was conducted in November 2022 aboard the USS Hyman G. Rickover. Cold spray was chosen over electroplating or component replacement, the latter requiring an unscheduled five-month dry docking, to repair damage to a component in a confined space. Completed in just eight days, this was NAVSEA’s first shipboard cold spray repair allowing the team to learn valuable lessons including thermal monitoring for cold weather applications and improving powder chemistry for better crevice corrosion resistance.

In April 2023, another groundbreaking repair was performed for the USS Essex. Both port and starboard rudder stocks were removed with extensive damage requiring repair and potentially delaying undocking. Cold spray repair enabled structural restoration on both rudder stocks, avoiding 24 days of additional dry dock time. Not only did the repair event demonstrate cold spray’s ability to meet or exceed structural and dimensional restoration standards under operational constraints but also allowed improvement in robotic integration, dust containment, and measurement techniques.

Utilizing lessons learned from above, Portsmouth Naval Shipyard recently achieved a deck plate repair of a component on the USS Virginia avoiding a 45-day unplanned docking. Drydock schedules are tight and adding an emergency dry docking usually affects multiple navy asset schedules. Prior to staging shipboard, the team conducted a mockup of the repair area allowing validation of space constraints, interferences and ventilation requirements.

Cold spray is proving to be a force multiplier for naval maintenance, combining innovative materials engineering with deck plate-level execution. It offers measurable improvements in readiness, cost avoidance, and mission continuity—transforming how the Navy approaches maintenance and sustainment in the modern era.

Graphic