Technology Title

Remanufacturing Execution (REX)

Tech Focus Area

Business Processes/Partnerships

Abstract

Problem Statement: The Department of Defense (DoD) currently uses different solutions to track and execute maintenance at depot installations, with separate systems for the Army, Navy, Marines, and Air Force. Shop floor systems are generally designed to integrate with Enterprise Resource Planning (ERP) systems. However, this integration often results in cumbersome processes that complicate shop execution. Costs and schedules recorded in ERP systems frequently do not align with what occurs on the shop floor, especially when multiple funding sources are assigned to a single asset being worked on in one location.

An execution system is needed that aligns with shop floor requirements while still providing ERP systems with the necessary data—without burdening shop personnel. The current misalignment leads to schedule delays, cost overruns, lack of asset visibility, and, most critically, increased risk of failing to meet quality, safety, and maintenance certification requirements.

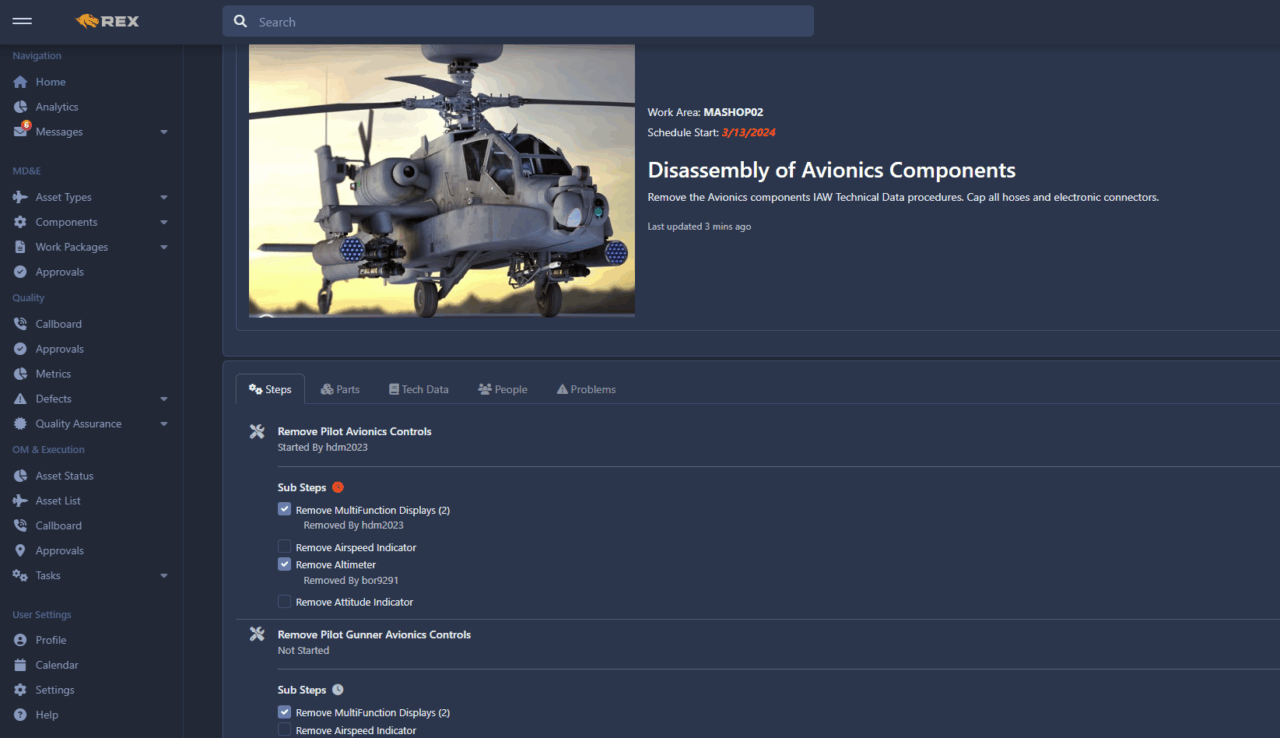

Description of Solution: The Remanufacturing and EXecution solution (Rex) is a cloud-based application that provides a unified platform for executing maintenance while offering full, real-time visibility of assets and their components. Rex recognizes asset structures so that as soon as an asset is disassembled, all components are automatically tracked and time-stamped to record status, touch times, and wait times.

Unlike ERP systems, Rex is not directly coupled with ERP process—by design. Instead, it maps shop floor cost and schedule data back into ERP systems to support cost, capacity, and scheduling requirements.

Key features include:

- Asset visibility: Ensures accountability for every defect, issue, or maintenance requirement.

- Integration with Army maintenance processes: Supports faults/status tracking and seamless transition of unit-level open requirements to depot-level systems with minimal data entry.

- Mobile accessibility: Enables shop personnel to update information in real time, improving mobility and reducing data entry delays.

- Secure hosting: Deployed in IL5 Azure Gov Cloud, allowing future integration with advanced technologies such as AI/ML and IoT hubs.

Rex also applies the P4T3 framework—Problem, People, Parts, Plan, Tools, Time—to ensure shops have the right context, resources, and schedules to execute tasks efficiently.

Benefits to the DoD:

- A single system to manage all maintenance execution requirements across services.

- Full visibility of assets throughout depot maintenance.

- Streamlined processes that reduce direct labor time.

- Reduced or eliminated quality defects through better accountability and execution.

Challenges

- Budget constraints may limit adoption of advanced technologies such as RFID tracking and expanded mobile device use.

Technical Maturity and Demonstration Results: Rex represents a new technology built on a proven concept. At Corpus Christi Army Depot this concept processed thousands of aircraft over 10 years.

Graphic