Technology Title

AirBoss’ Enhanced Durability Track Pads for Bradley Fighting Vehicles: A Cost-Effective Solution for Improved Readiness

Tech Focus Area

Reliability Improvement

Abstract

Problem Statement: The Bradley Fighting Vehicle (BFV) is a critical combat platform in the United States Army, yet readiness is constrained by premature wear and limited-service life of current track pads. Although specified to last 1,500 miles, pads often fail sooner under operational conditions. Harsh environments—desert heat, abrasive sand, and extended road marches—accelerate degradation and pad separation. These early failures drive frequent replacements, higher sustainment costs, and reduced availability. The Army requires a more durable, cost-effective pad solution to extend service life, cut maintenance demand, and improve overall readiness.

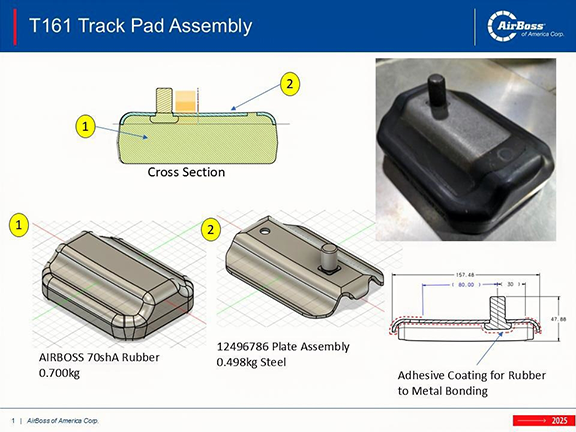

Description of the Innovation Solution: AirBoss of America has developed a next-generation rubber formulation and manufacturing process for the T161 track pad (NSN 5340-01-587-6763) used on the BFV. Advanced elastomer compounding, improved bonding, and tightly controlled molding deliver a pad that exceeds Army specifications. Formal testing at Aberdeen and Yuma Proving Grounds demonstrated service life more than 50% longer than the Army's 1,500-mile threshold, reducing replacements by as much as 35%.

Benefits to the DoD: For approximately 3,000 active BFVs, each requiring 82 pads, standard operations would consume ~246,000 pads per full fleet cycle. Next-generation AirBoss pads would require only about 160,000—a 35% reduction, avoiding ~86,000 replacements. Based on the Army's BFV track pad procurement cycle, pads are typically replaced every 2–3 years; with AirBoss pads, this interval could extend to 3–4 years. In financial terms, at a notional $20 per pad, savings exceed $1.7M per fleet cycle. Across ~12,000 active tracked vehicles—including BFVs, M113, Armored Multi-Purpose Vehicle, M1 Abrams, M109 Paladin, M270 MLRS, and various recovery and engineer vehicles—pad demand would drop from ~984,000 to ~640,000 per cycle, avoiding ~344,000 replacements. At a notional $20 per pad, this equates to ~$6.9M in cost avoidance per cycle. Fewer replacements also lower maintenance labor, logistics burden, and vehicle downtime, strengthening readiness.

Innovation Challenges: Adoption requires qualification testing, technical data, source approval, and proof of certified quality systems with MIL-STD compliance. AirBoss has achieved these standards on other defense products and has the capacity, systems, and scalability to support program requirements.

Technical Maturity / Demonstration Results: The AirBoss pad has been validated through Army testing at Aberdeen and Yuma and is assessed at TRL 7 and MRL 7, representing a production-representative prototype demonstrated in an operational environment. With ISO 9001, IATF 16949, and ISO 14001 certifications, AirBoss maintains robust quality systems and scalable production. This U.S.-manufactured solution delivers a qualified, durable, and cost-effective track pad that enhances readiness while reducing total ownership cost.

Graphic