Technology Title

Deployable Offline AI/ML Servers for Zero-Connectivity Environments with Interactive 3D Maintenance

Tech Focus Area

Enhanced Inspection

Abstract

Problem Statement: DoD maintenance operations often occur in austere, disconnected, or classified environments where internet connectivity is limited or non-existent. In such settings, current digital maintenance systems fail to deliver mission-critical support due to their reliance on cloud access, lack of offline AI functionality, and dependence on static technical documentation. Technicians must frequently rely on outdated paper manuals, tribal knowledge, and trial-and-error troubleshooting. The absence of secure, interactive, and intelligent tools in these environments leads to increased downtime, reduced readiness, and higher sustainment costs across platforms and services.

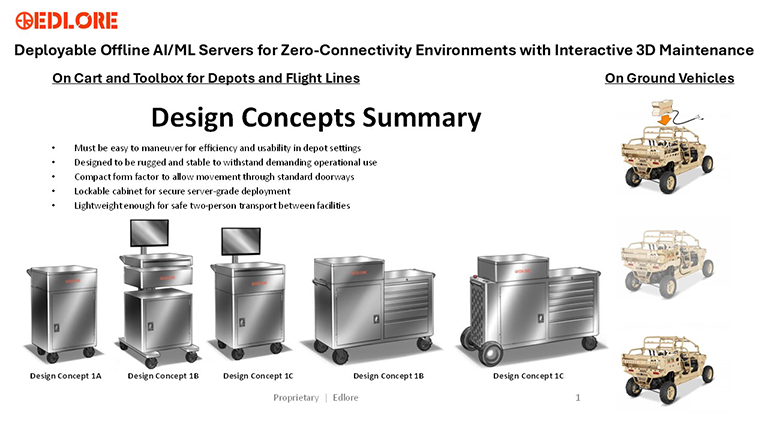

Description of the Innovation Solution: The Edlore AI-Server is a ruggedized, edge-based computing platform that brings AI-powered maintenance intelligence directly to the point of need, without any requirement for internet or cloud connectivity. Designed to be mounted on mobile carts, toolboxes, or ultralight vehicles (UTVs), the server hosts an interactive 3D viewer, embedded technical manuals, and offline AI capabilities that allow users to search procedures, ask maintenance questions, access animations, and view parts metadata in real time. The system converts legacy tech orders into dynamic procedures with voice-assisted navigation, drag-and-drop editing, and embedded parts ordering. It also includes peer-to-peer synchronization for secure data sharing and records all service interactions, updates, and field-captured inputs such as notes and images. This solution ensures maintainers can access the full suite of technical data, even in communications-denied or cyber-contested environments.

Benefits to the DoD: The Edlore AI-Server significantly improves field-level and depot maintenance capabilities across the Services. It:

- Enables full functionality in offline conditions, supporting distributed operations and continuity of maintenance

- Reduces mean time to repair (MTTR) by delivering AI-driven troubleshooting guidance and interactive 3D models

- Enhances training and knowledge retention with visual, voice-guided, and hands-on procedural content

- Increases security through localized data storage and NIST-compliant architecture

- Fosters cross-platform and cross-OEM standardization by integrating legacy content into a unified platform

- Promotes faster onboarding of new maintainers with intuitive, user-centered interfaces

Innovation Challenges: Development of the Edlore AI-Server required overcoming key challenges, including:

- Delivering advanced AI models that function reliably without cloud access

- Designing intuitive user interfaces for low-distraction, gloved-hand, or voice-only interaction

- Ensuring modular hardware performance while meeting MIL-STD-810H ruggedization and thermal limits

- Synchronizing data securely across units via peer-to-peer protocols

- Integrating diverse OEM technical content and 3D assets into a universal architecture

Technical Maturity / Demonstration Results: The AI-Server platform is currently at TRL-6, with prototypes undergoing evaluation at Air Force sustainment facilities. Demonstrations have validated its ability to function fully offline, host interactive 3D maintenance workflows, and deliver AI-assisted troubleshooting and procedure-building tools. A cart-mounted concept is a continuation of the same project and the UTV-mounted variant as shown in the Graphics, is for a new Marine Corps project. User feedback from initial testing has shown measurable reductions in repair time, increased maintainer confidence, and demand for immediate field deployment. Future iterations will integrate wearable AR interfaces and biometric feedback to further enhance technician effectiveness and safety.

Graphic