3M Govt Markets Navy

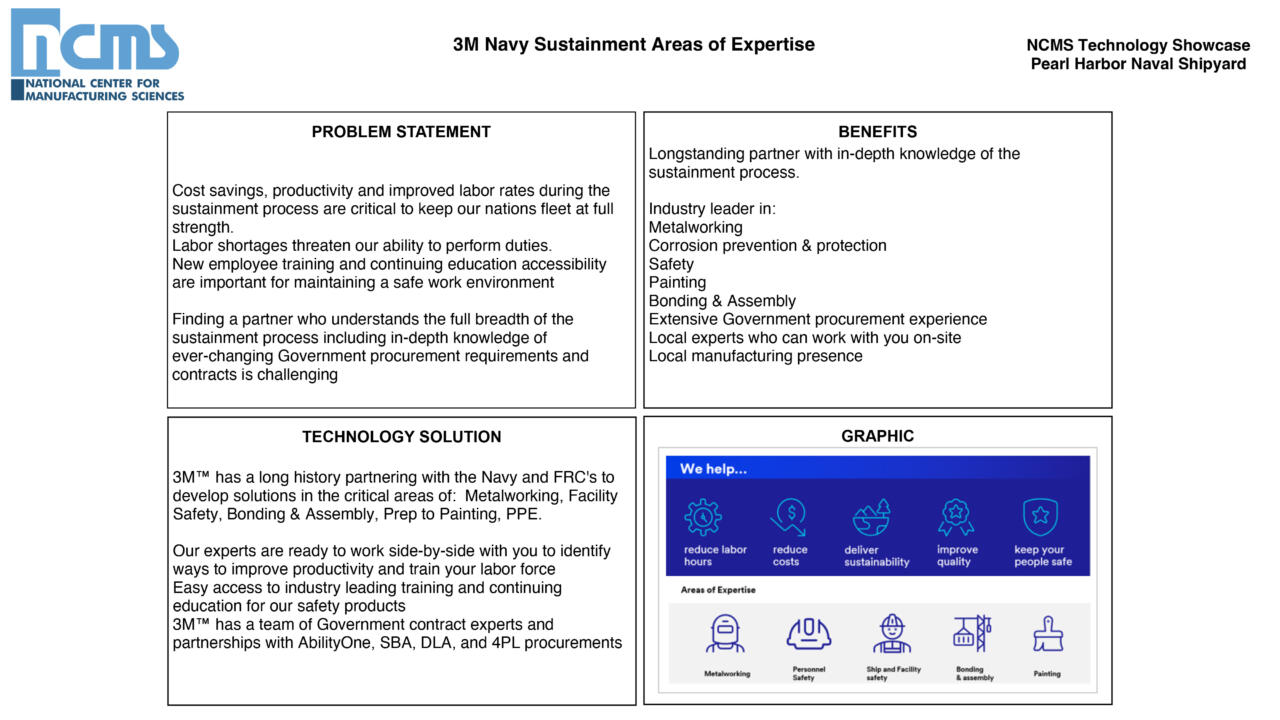

3M has a long history partnering with the Navy and shipyards to develop solutions in the critical areas of:

- Metalworking

- Ship, Personnel, Facility Safety

- Bonding & Assembly

- Painting

Our experts are ready to work side-by-side with you to identify ways to improve productivity and train your labor force.

Easy access to industry leading training and continuing education for our safety products

3M has a team of Government contract experts and partnerships with AbilityOne, SBA, DLA, and 4PL procurement sources.

Safety Compliance with Cubitron III Abrasive Technology

Adapt Laser

For over 20 years, we've been providing state-of-the-art laser cleaning systems to government agencies and customers with high-quality cleaning needs, such as the nuclear, military & defense, welding, automotive, infrastructure, and aerospace industries.

Our technology ranges from 20 to 1,600 watts of laser power to ensure we can provide services to a large scope of clients, including those who need to remove dangerous coatings and nuclear radiation without damaging the product in any way.

We deliver complete and high-end solutions, clean products with no damage, have the highest quality cleaning possible, and enable time, quality, and cost benefits.

Our laser cleaning units can be either handheld or automated, ensuring that we can offer you the best cleaning strategy for your specific application needs. Paired with our top-notch air filtration systems, our lasers safely remove contaminants and capture them at the source where they can be easily disposed of.Focus Area: Coating and Corrosion Prevention

Contact

Laser Ablation

American Ceramic Technology

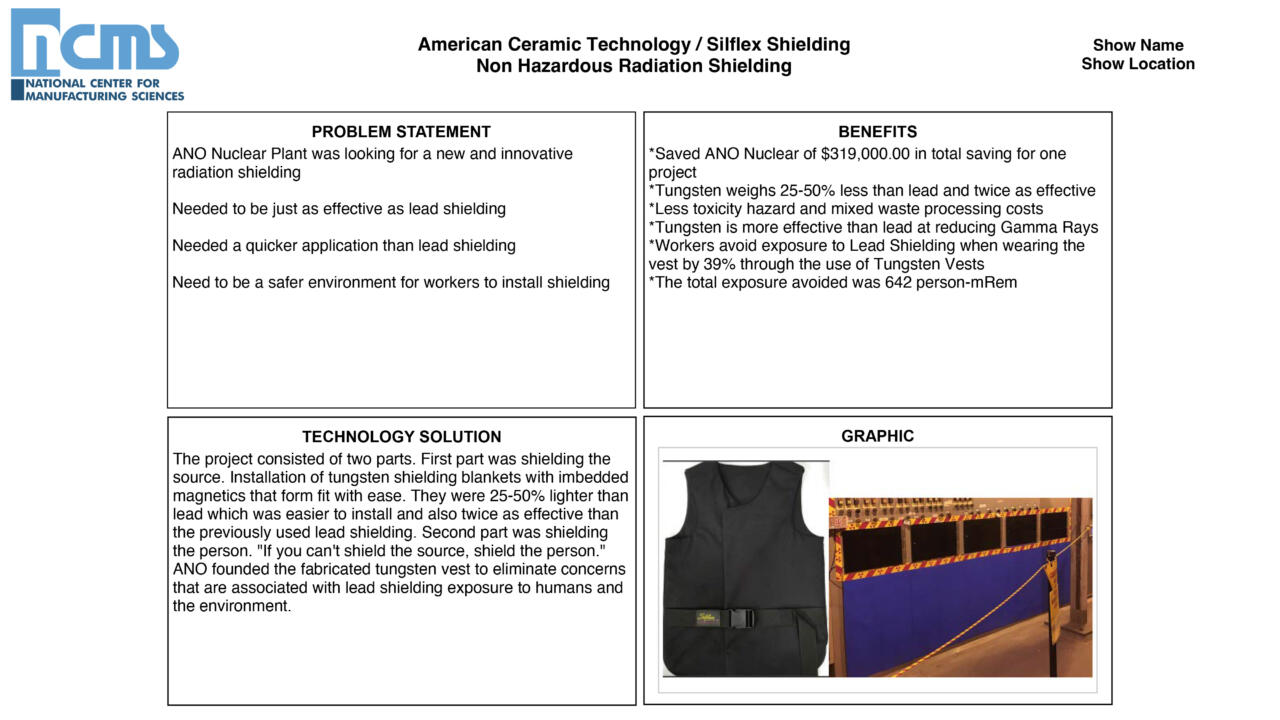

American Ceramic Technology, Inc. is the ISO 9001:2015 manufacturer of Silflex® Shielding, the award winning nonhazardous, non-lead radiation shielding. In 2005, Silflex® tungsten shielding was developed and certified by Entergy and ANO in 2007 for use in the nuclear industry. We have expanded into the medical, military, NDT, mining and oil & gas industries. Manufacturing is located in California and South Carolina. We have many radiation shielding materials and product options designed with a flexible silicone base. We design custom solutions to help customers achieve their ALARA goals. Silflex® shielding is designed for maximum radiation dose reduction during operation and installation to protect personnel and equipment. American Ceramic Technology’s innovative technology allows nuclear power plants, laboratories and naval reactors to provide a safer, cleaner and more efficient work environment.

Focus Area: Energy, Environmental, Health, and Safety

Contact

Non-hazardous radiation shielding

ARIS Technology

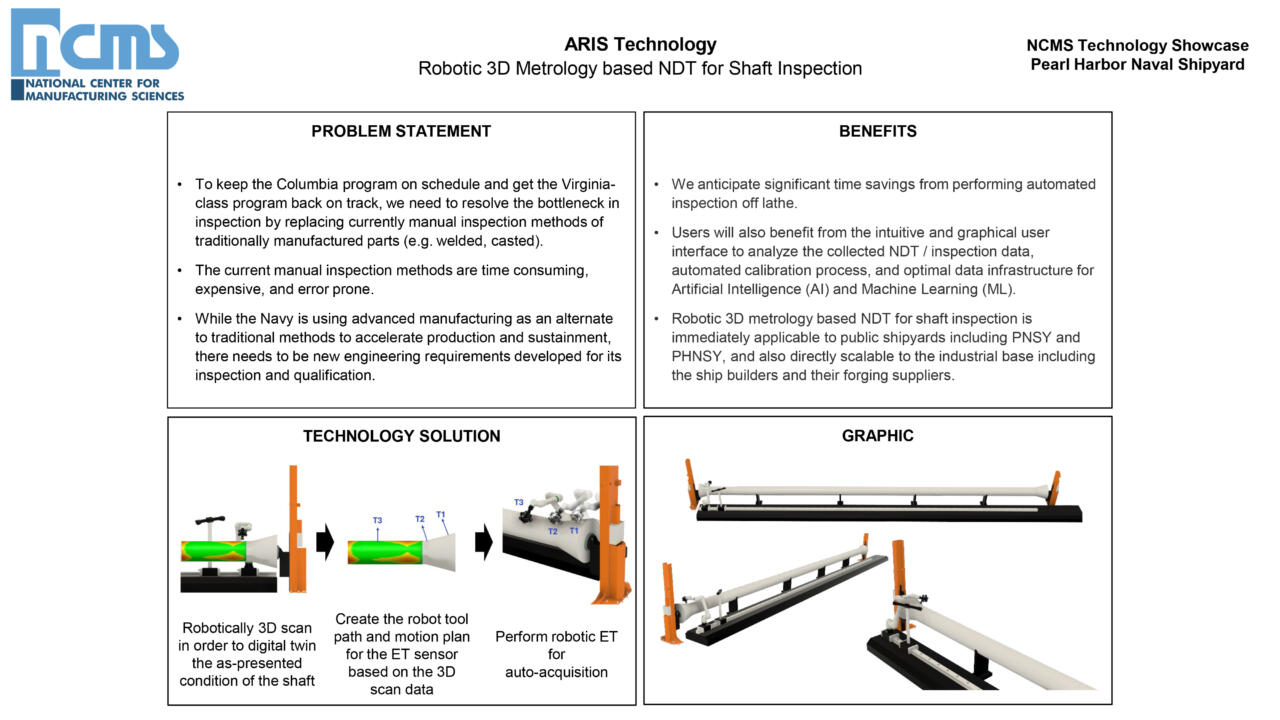

ARIS Technology provides an end-to-end solution for automated metrology and inspection. ARIS is a platform technology company, with core competency in integrating fully-automated turnkey robotic inspection systems with an intuitive User-Experience (UX) and Artificial Intelligence (AI).

Using its technology platform, ARIS can rapidly integrate and test various vendor agnostic sensors, including 3D scanning, 2D vision, and NDT (Non-Destructive Testing). Our robotic systems can be configured to scale in size, ranging from a mobile pushcart for in-machine / in-process inspection to a large overhead gantry system to inspect an entire vehicle. For PHNS & IMF, a relevant system option would be a robotic NDT system for shaft inspection. ARIS is currently working with NAVSEA 05 to support modernization of requirements for auto-acquisition and accelerate adoption of robotic inspection systems at shipyards.

Operators can intuitively program ARIS systems with little training. Our systems are digital twinned allowing operators to visualize the intended operation and validate it mitigating risks. They can interact with and program ARIS systems with various human-robot interaction (HRI), including collaborative robot (Cobot) programming, AI-guided programming, Virtual Reality (VR) / Augmented Reality (AR), and human-to-robot learning (i.e. a robot learning from operators' hand operations).

Focus Area: Enhanced Inspection

Contact

Intelligent & Intuitive Robotic 3D Inspection and NDT System

ATT Metrology Solutions

Formed in 1988 as a pioneer in precision measurement and inspection services, ATT is today the premier provider of technology-enabled metrology services and integrated systems to leading precision-manufacturing sectors in North America.

ATT specializes in the provision of large-scale 3D precision measurement systems to high-value market segments, principally in aerospace, defense, shipbuilding, nuclear, hydro-electric, and heavy industry.

Offering:

1. 3D SCANNING

2. AUTOMATION TECHNOLOGIES

3. PRECISION MEASUREMENTS

4. INSPECTION

5. REVERSE ENGINEERING

6. DIGITAL TWINS FOR AUGMENTED REALITY / VIRTUAL REALITY

7. REMOTE VISION EQUIPMENT

8. MAINTENANCE AND CALIBRATION SERVICES

9. COLLABORATIVE ROBOTS FOR INDUSTRIAL APPLICATION

10. INSPECTIONS (tank and voids)

11. DIGITAL TWINS FOR INDUSTRIAL AUGMENTED REALITY

12. ROBOTICS

13. COORDINATE MEASURING MACHINE (CMM)Focus Area: Enhanced Inspection

Contact

Brian Burton

206.940.3587

brianb@attinc.com

www.attinc.com

Digital Twin Data Collection Services

Bardex Corporation

Bardex® provides novel engineering insights and designs, prototypes, and manufactures proprietary equipment to solve the marine industry’s heaviest challenges. For over 60 years – and 300+ projects for shipyards, ports, and the offshore energy industries, the Bardex mindset has always been to be a trusted, collaborative partner whose first step in any project is to understand exactly what the client needs to accomplish. That approach has produced more than 20 patents, many repeat clients, and countless innovations that make the seemingly impossible possible, while improving safety, efficiency, and our clients’ profitability for a diverse range of applications. Bardex facilities are ISO 9001, ISO 14001, and ISO 45001 certified. To learn more, visit https://www.bardex.com , and follow them on LinkedIn to stay in touch.

Focus Area: Energy, Environmental, Health, and Safety

Contact

OmniLiftTM Launch & Retrieval Systems

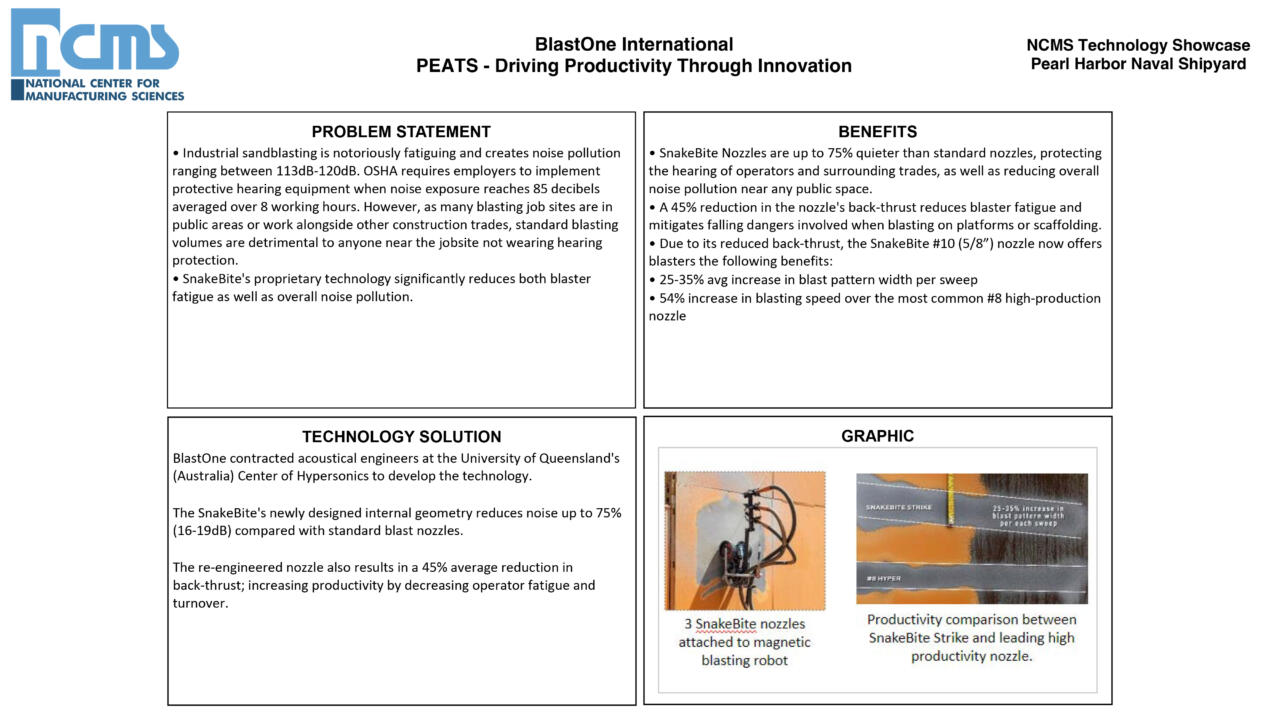

BlastOne International

Originally established nearly 50 years ago to provide technical consulting, BlastOne has grown to become a single source supplier of blasting equipment, abrasives and know-how to customers all over the world. BlastOne operates internationally from several offices across Australia, New Zealand, North America and Europe. We stand behind our brand claim of superior performance. It’s something we define as ‘Performance3’—the result of combining superior know-how with superior abrasives and superior equipment. In short, it delivers greater cost-efficiencies for our customers.

Focus Area: Coating and Corrosion Prevention

Contact

Chloe Meisner

chloe.meisner@blastone.com

614-695-5794

www.blastone.com

PEATS – Driving Productivity Through Innovation

Booz Allen Hamilton

Booz Allen provides management and technology consulting, analytics, engineering, digital solutions, mission operations, and cyber services to clients across the DoD, federal, civil, and commercial clients. We help clients stay ahead in an era of constant change, and we transform missions with tomorrow’s technologies to advance the country’s most critical civil, defense, and national security priorities. Trusted as the largest provider of AI to the federal government, we combine leading AI, cybersecurity, and engineering with emerging tech to deliver results at the heart of our clients’ missions. Booz Allen has developed products, solutions and mission capabilities that support and advance NAVSEA and the Shipyard enterprise mission, including immersive training and mixed-reality maintenance applications, machine learning (ML) and AI-augmented solutions for cyber defense, 5G private networks, digital data management, and more, through our 15 years of partnership in shipyard IT maintenance and modernization.

Focus Area: Workforce Development/Visualization

Contact

Joseph Reck

Reck_Joseph@bah.com

360–440–8960

Immersive Tech Mixed Reality Maintenance Training

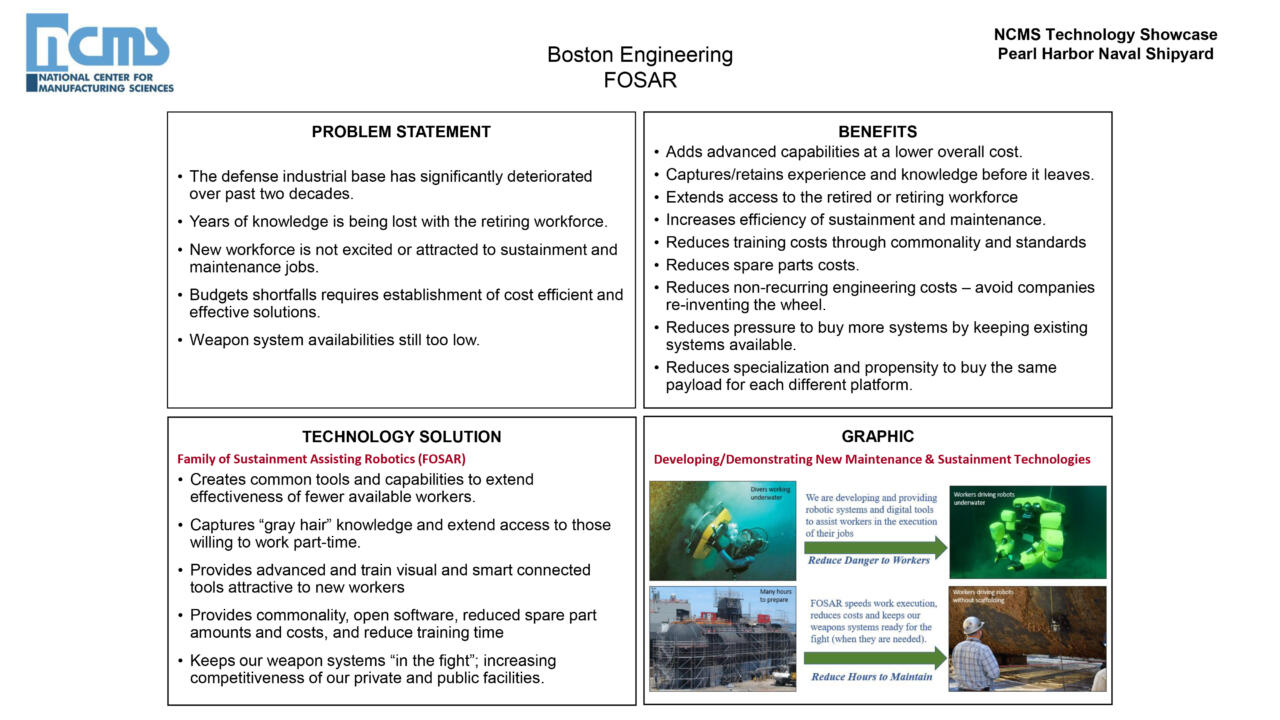

Boston Engineering

Boston Engineering is a leader in sustainable digital transformations, implementing innovative technologies, and developing road maps to solve tomorrow’s business challenges. Leveraging the latest in emerging technologies, such as Sustainment Robotics (SR), Augmented Reality (AR), Virtual Reality (VR), Internet of Things (IoT), and more, Boston Engineering helps you bring innovation to bear on your mission. Whether leading ideation, developing proofs of concept, building consensus, providing training, or handling post implementation support, simply Image the Possibilities and Boston Engineering will expand your capabilities to innovate.

FOSAR

Box

Box (NYSE:BOX) is the Cloud Content Management company that empowers enterprises to revolutionize how they work by securely connecting their people, information and applications. Founded in 2005, Box powers more than 87,000 businesses globally, including AstraZeneca, General Electric, P&G, and The GAP. Box is headquartered in Redwood City, CA, with offices across the United States, Europe and Asia. To learn more about Box, visit http://www.box.com/.

Focus Area: Advanced/Additive Manufacturing

Contact

Tom Gallagher

410.271.6692

tgallagher@box.com

www.box.com

Content Cloud

CDW-G

CDW-G is a leading multi-brand provider of information technology solutions to business, government, education and healthcare customers in the United States. We help our customers navigate an increasingly complex IT market and maximize return on their technology investments. Our broad array of products and services range from hardware and software to integrated IT solutions such as security, cloud, hybrid infrastructure and digital experience.

Focus Area: Business IT and Analytics

Contact

Gina Kang

Gina.kang@cdwg.com

www.cdwg.com

Value Added Reseller

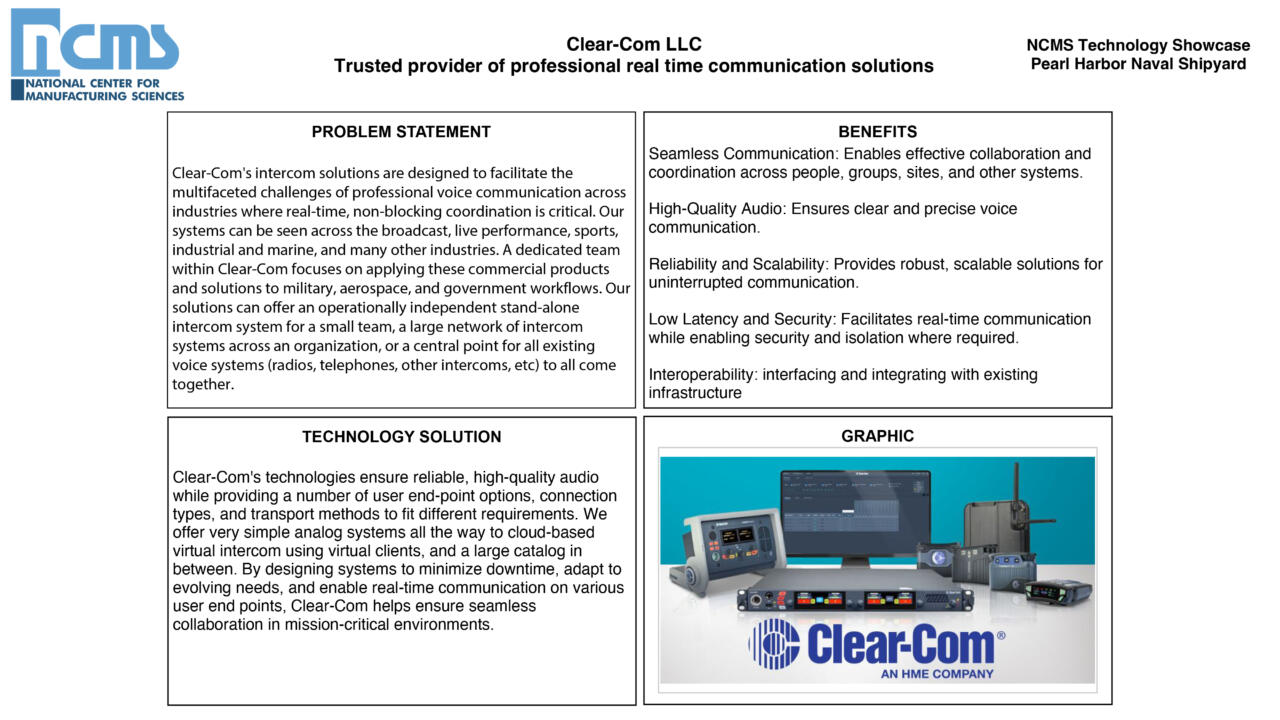

Clear-Com LLC

Clear-Com, an HME company, is a trusted global provider of professional real-time communications solutions and services since 1968, innovating market proven technologies that link people together through wired and wireless systems. Clear-Com was first to market portable wired intercom systems for live performances. Since then, our history of technological advancements and innovations has delivered significant improvements to the way people collaborate in professional settings where real-time communication matters. For the markets we serve — broadcast, live performance, live events, sports, military, aerospace and government– our communication products have consistently met the demands for high quality audio, reliability, scalability and low latency, while addressing communication requirements of varying size and complexity. Our reputation in the industry is not only based on our product achievements, but also on our consistent level of customer engagement and dedication to delivering the right solutions for specialized applications, with the expertise to make it work.

Focus Area: Advanced/Additive Manufacturing

Contact

Trusted provider of professional real time communication solutions

ClearObject

ClearVision prioritizes data security and integrity through edge computing capabilities. Processing data locally ensures low-latency analysis and reduces reliance on external networks, safeguarding sensitive information. Our solutions are built on a foundation of secure software development, adhering to strict security protocols and compliance standards.

Partner with ClearObject to revolutionize your military equipment lifecycle with the power of AI.

Focus Area: Advanced/Additive Manufacturing

Contact

ClearVision – Vision AI Solutions

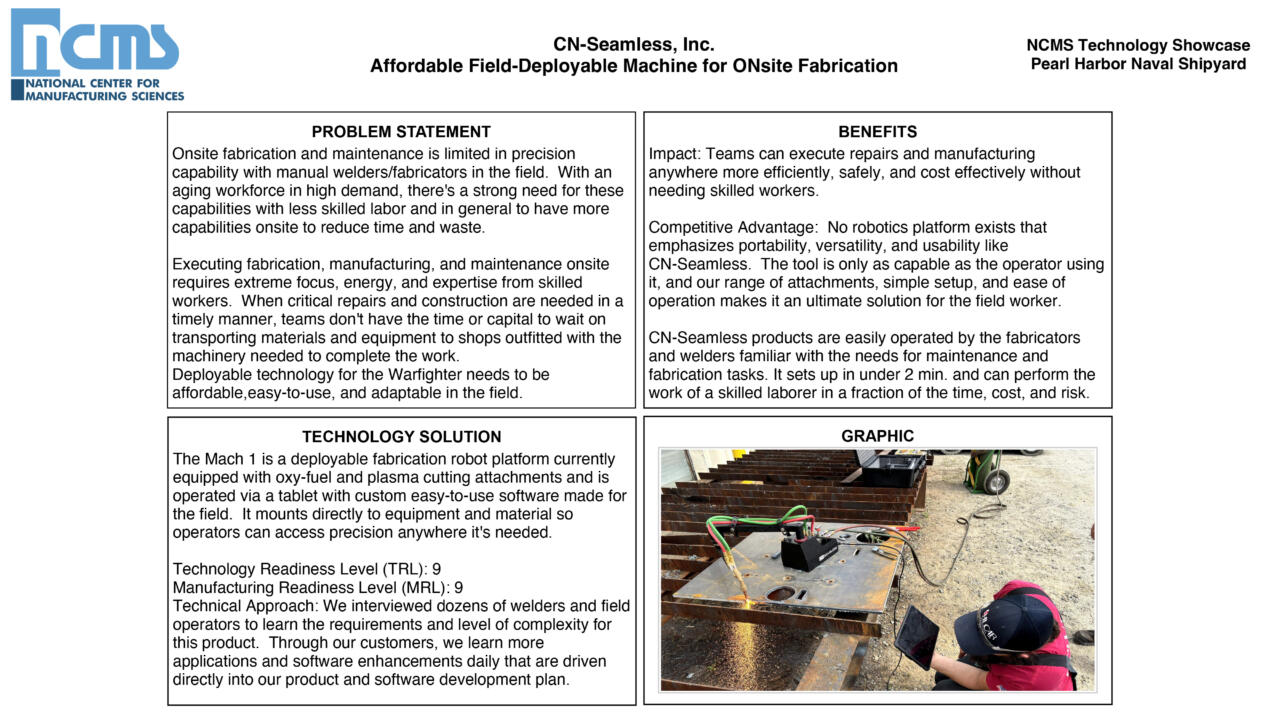

CN-Seamless Inc.

CN-Seamless designs portable automation equipment for heavy metal cutting with plasma or oxy-fuel. Their product is easy to operate, it deploys in under a minute directly to the metal being cut (even vertically), and is a game changer for ship building, repair and general structural maintenance/construction. They further have an SBIR grant to develop additional attachments for welding, laser cutting, inspection, corrosion removal (plasma & laser cleaning), marking, and more that will adapt to the existing system.

Furthermore, CN-Seamless designs and manufactures the full Mach 1 system from mechanical, to electrical, to software design. They emphasize ease of use of the machine and successfully launched the Mach 1 in steel fabrication, shipbuilding, oil & gas, automotive manufacturing, construction equipment repair, mining, and several other heavy industrial markets. They offer the full Mach 1 system for under $10,000 and are seeking support from Navy and Air Force leaders interested in the technology to bring price down and develop further capabilities to make the Mach 1 the ultimate deployable maintenance machine for the DoD.

They envision a future in which the warfighter can keep an arsenal of the modular attachments and be equipped for any maintenance/repair/construction job they encounter in the field or the shop. With skilled labor becoming harder to find, they believe the automation of difficult tasks with a highly portable, easy-to-use machine will be a game changer for future MRO teams.

Affordable Field-Deployable Machine for Onsite Fabrication

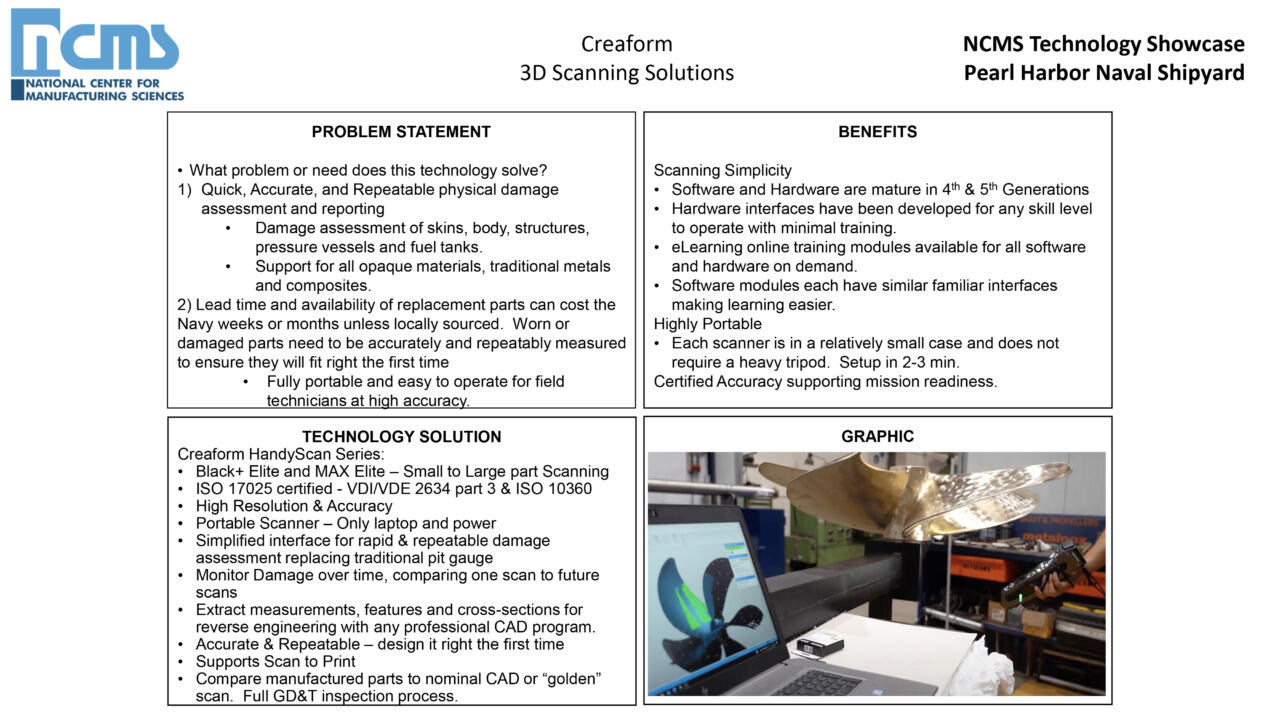

Creaform

Creaform develops, manufactures and markets cutting edge portable 3D measurement and analysis technologies that increase productivity. Creaform offers innovative solutions for applications such as 3D scanning, reverse engineering, quality control, non-destructive testing, product development, and numerical simulation (FEA/CFD). Its products and services cater to a variety of industries, including automotive, aerospace, consumer products, heavy industries, healthcare, manufacturing, oil and gas, power generation, research and education.

With headquarters and manufacturing operations in Lévis, Québec, Creaform operates innovation centers in Lévis and Grenoble France, and has direct sales operations in Canada, USA, Mexico, Brazil, France, Germany, Italy, Spain, China, Japan, Korea, Thailand and Singapore.

Creaform is a unit of AMETEK Ultra Precision Technologies, a division of AMETEK Inc., a leading global manufacturer of electronic instruments and electromechanical devices, with annual sales of approximately $4.0 billion.

Customers benefit from fast, accurate, repeatable measurements. Creaform technologies make it possible to measure in the real world without loss of accuracy.Focus Area: Enhanced Inspection

Contact

Mike Walsh

415.298.2432

mike.walsh@ametek.com

https://www.creaform3d.com/en

Creaform 3D Scanning Solutions

DIT-MCO International

For cable testing, harness testing and other automated product testing, customers rely on DIT-MCO wiring analyzers. DIT-MCO is your complete solution provider for electrical testing of cables, harnesses, wired boxes, panel assemblies and more. From simple cables to complex assemblies requiring EE & LM, DIT-MCO has the solution. We also provide custom adaptation and test programming, giving you a complete turnkey solution.

Technology Title

DMG MORI Federal Services

The DMG MORI Group is a leading innovator in the machine tool industry with an expansive portfolio of manufacturing equipment. We are focused on customer support, quality, service, and advanced technology. Our product line includes 5-Axis Milling machines, 4 and 5-Axis Horizontal Machining Centers, Additive machines, Hybrid machines, Vertical Machining Centers, CNC Turning machines, CNC Boring mills, and a variety of Palletized systems and Grinding machines. With over 12,000 team members world-wide, our group companies specialize in providing unmatched applications support, service and training to large OEMs, Tier-one contractors, and the US government itself. DMG MORI Federal Services (DMFS) works exclusively with US federal and State government agencies to support government initiatives while focusing on federal acquisition regulations and cybersecurity compliance. DMFS is also (ITAR) Registered, (CMMC) 2.0 complaint ready, and (NIST) compliant. We currently have active projects with the Army, Navy, Air Force, Department of Energy, and NASA.

Focus Area: Advanced/Additive Manufacturing

Contact

Kevin Pasiola

224.451.5137

kpasiola@dmgmore-fs.com

https://dmgmori-fs.com/

DMG MORI Advanced Manufacturing and Additive Manufacturing Solutions

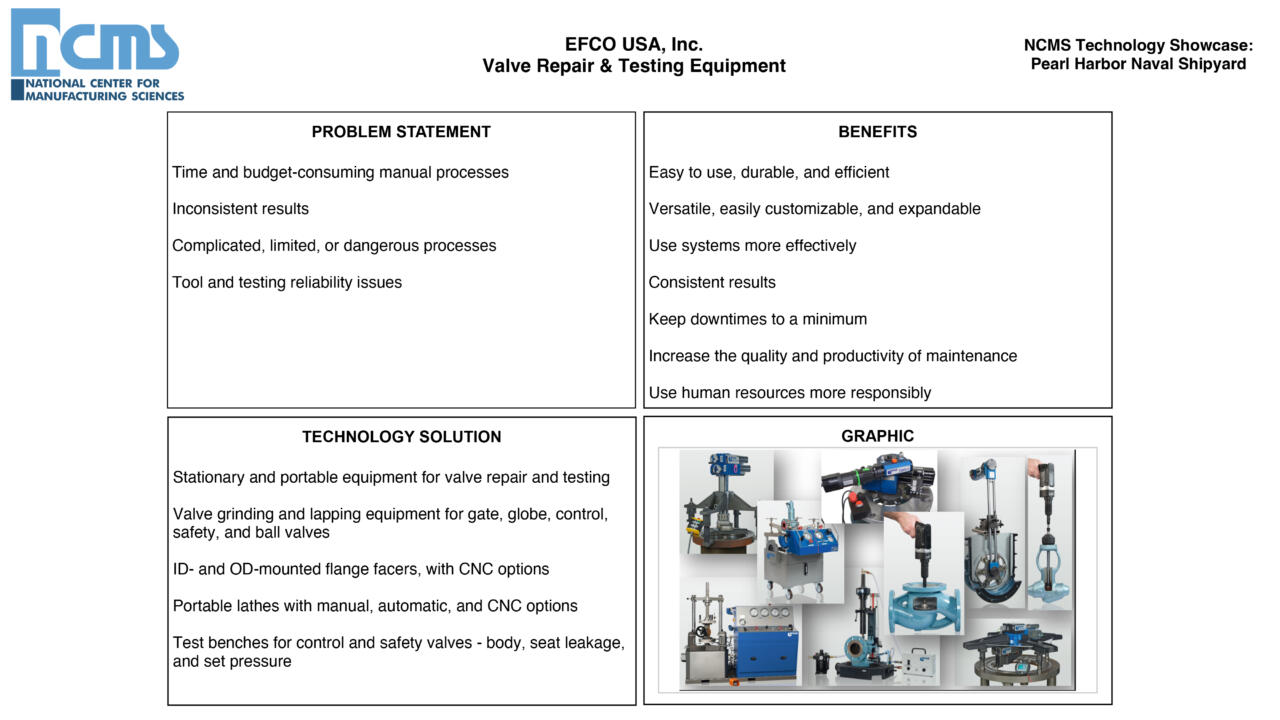

EFCO USA, Inc.

Established in 1978, EFCO has been a world-leading manufacturer of portable and stationary valve repair and testing equipment. Wherever fittings, valves, and pumps are used, EFCO equipment is also needed to maintain, repair, and test sealing surfaces, shut-off bodies, and housings. We are a family-run business with the philosophy of making our customers our partners – working together to create machining and testing solutions. Customer experience from the extensive use of our machines continuously contributes to our product development.

EFCO equipment is used worldwide, certified to DIN EN ISO 9001, and is characterized by our quality, durability, easy handling, and superior results. Our product range for in-shop and in-field service includes portable and stationary grinding and lapping equipment, flange facers, portable lathes, test benches, and workshops for valves, flanges, and pipelines.Focus Area: Workforce Development/Visualization

Contact

Sales

800.332.6872

sales@efcousa.com

Valve Repair & Testing Equipment

Entry Point International, LLC

Entry Point International, LLC specializes in providing innovative temporary protection solutions for the construction and defense industries, with a strong focus on reducing rework, delays and associated costs. We offer lightweight, Flame-Retardant products that protect surfaces such as decks, bulkheads, topsides, equipment, and more especially in high-traffic and sensitive environments. Our products come in seven densities to accommodate varying levels of traffic and are certified to meet critical safety standards including ASTM-E648 Class 1, NFPA-701 and LPS 1207. With a proven track record of success, we help contractors and government agencies reduce the use of expensive and labor-intensive materials such as fire-rated plywood. Our primary customers are construction firms, DoD contractors, and shipyards, including naval facilities, who need high-quality protective solutions during maintenance and repair projects. By delivering durable, reliable, and cost-effective protection, we enable our clients to focus on their core operations without concern for surface damage or fire hazards.

Focus Area: Energy, Environmental, Health, and Safety

Contact

Kerry Sullivan

866.664.3129

administration@entrypointusa.com

www.entrypointusa.com

Cost Reduction due to Improvements in Temporary Protection of Coating and Finishes in Naval Shipbuilding Panel: Surface Preparation & Coatings

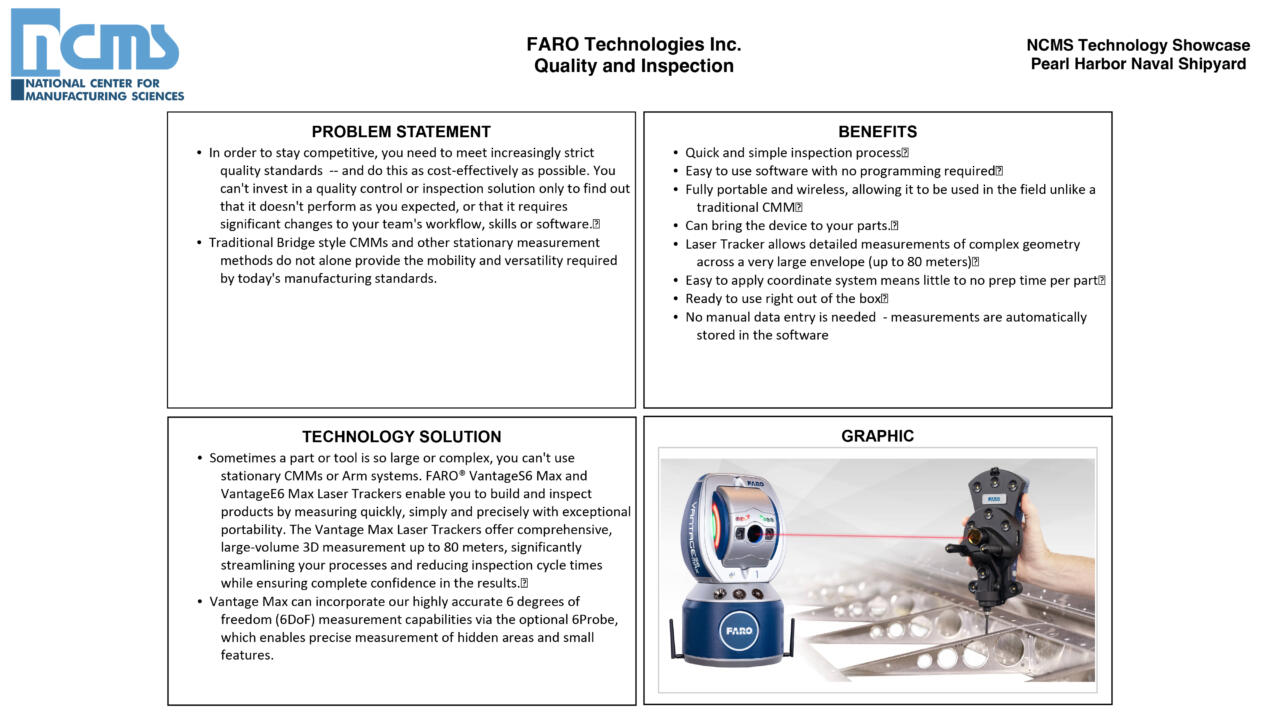

FARO Technologies, Inc.

FARO is the leading global source for 3D measurement, imaging and realization technology. For 40 years, FARO has provided industry-leading technology solutions that enable customers to quickly and easily measure their world, and then use that data to make smarter decisions faster. FARO continues to be a pioneer in bridging the digital and physical worlds through data-driven reliable accuracy, precision and immediacy. FARO’s global headquarters is located in Lake Mary, Florida. The company also has a technology center and manufacturing facility located in Exton, Pennsylvania, containing research and development, manufacturing and service operations.

Focus Area: Advanced/Additive Manufacturing

Contact

Ivan Barrow

360.920.1745

ivan.barrow@faro.com

www.faro.com

Quality and Inspection

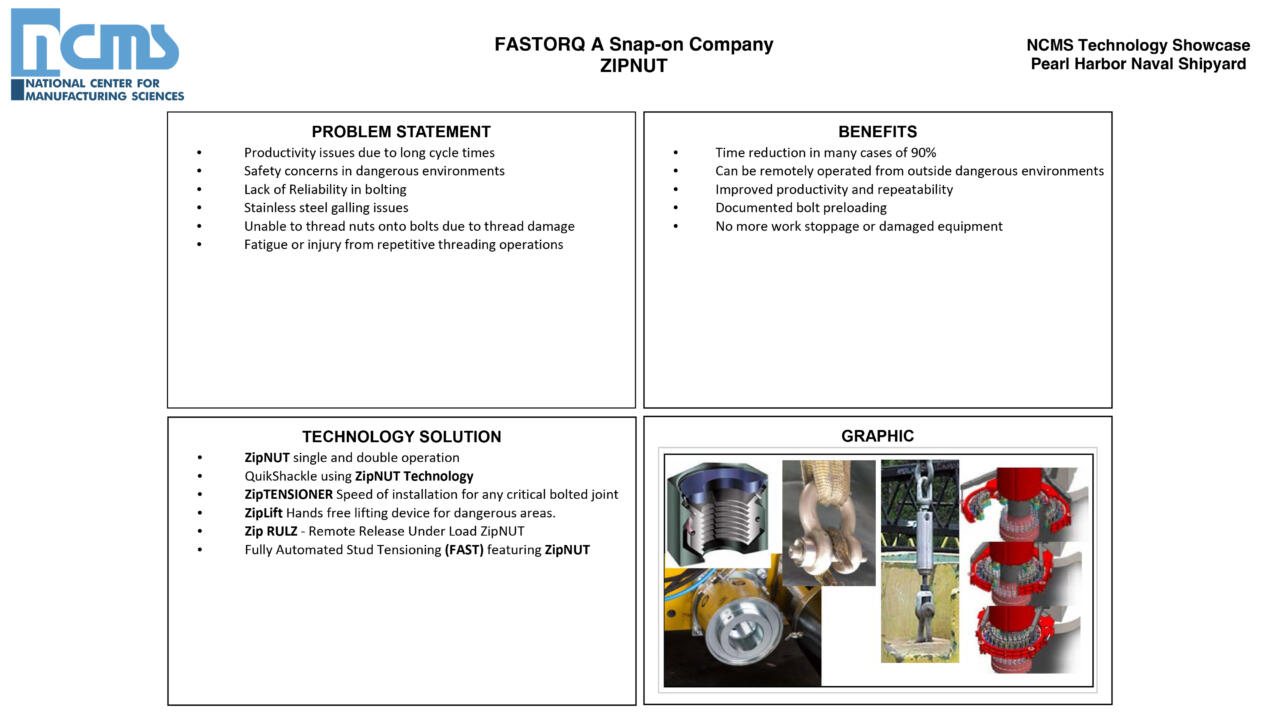

FASTORQ A Snap-on Company

FASTORQ, based in New Caney, Texas, is the preferred global provider of precision bolt loading and removal solutions. A wholly owned subsidiary of Snap-on Corporation since 2018, FASTORQ is a pioneer of the hydraulic tools industry and today designs, manufactures, and sells a revolutionary line of bolting solutions. FASTORQ is the only company that has a complete line of hydraulic and pneumatic tools, as well as design resources to customize existing tools or create one-of-a-kind bolting solutions. The company also produces a proprietary line of specialty bolting lubricants. FASTORQ’s highly skilled team of engineers and bolting technicians deliver timely resolution to bolting challenges of all sizes. FASTORQ customers include a wide range of industrial applications: Heavy Equipment, Military, Aerospace, Subsea Construction and Intervention, Oil & Gas Services, Petrochemical, Refinery, Power Generation, Oil & Gas Drilling & Exploration, Pipeline Construction & Maintenance, Pulp & Paper, and Mining.

Focus Area: Reliability Improvement (Hardware)

Contact

Mark Murphy

Mark.j.Murphy@snapon.com

303-619-4602

ZIPNUT

FONON Technologies

Fonon Technologies is a leading laser R&D and manufacturing company that provides military-grade, trade-compliant laser solutions. Fonon’s elite team of scientists and engineers develops stable processes for disruptive technologies, offering safer, chemical-free alternatives. Fonon’s lasers remove rust, paint, and corrosion, and ensure traceability in defense applications, fostering healthier work environment while enhancing productivity and efficiency.

Focus Area: Coating and Corrosion Prevention

Contact

Jennie Mathes

423.271.5835

jmathes@laserphotonics.com

www.fonon.us

DefenseTech Handheld Laser Cleaning System

Frham Safety Products, Inc

Frham Safety Products, Inc is the largest radiation protection company in the USA. When Frham went into business in 1983, it was based on the idea of manufacturing and distributing products to the nuclear power utilities and related users of safety supplies and equipment. Frham has extended its markets to include the Department of Energy, Department of Defense, and nuclear plants worldwide.

Focus Area: Energy, Environmental, Health, and Safety

Contact

Changing the protective Clothing Paradigm in the USA

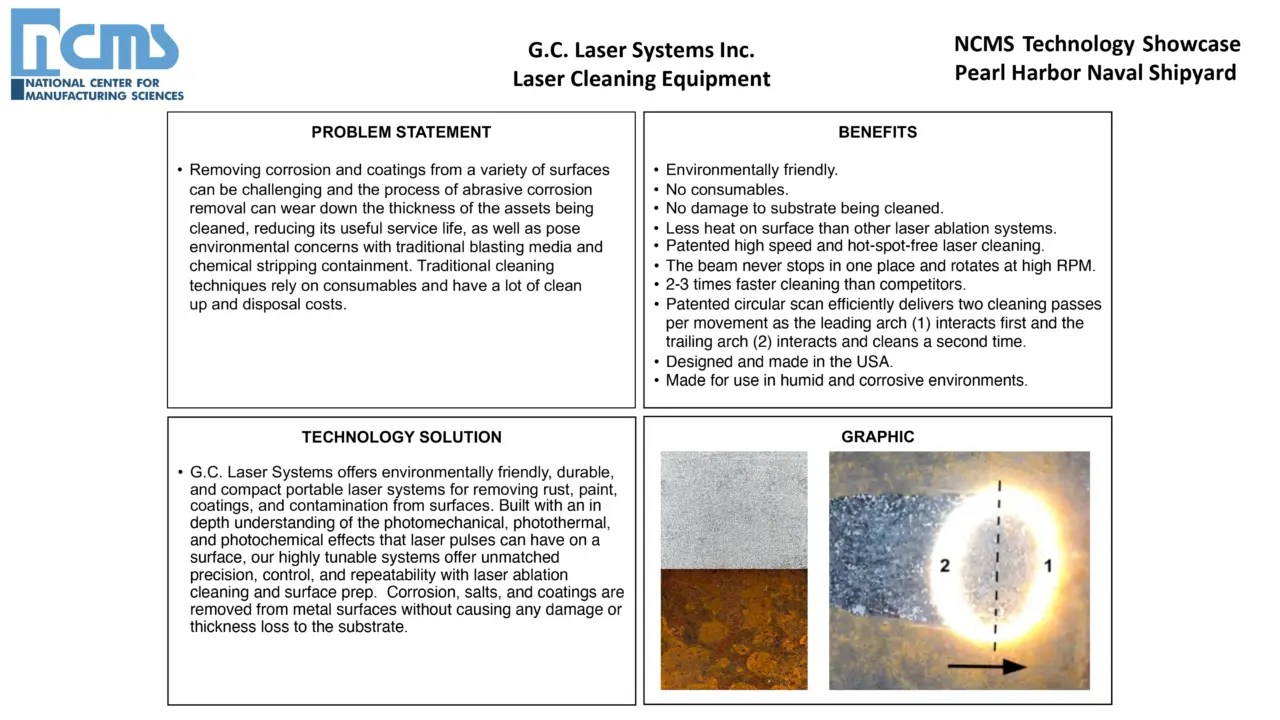

G.C Laser Systems Inc

G.C. Laser Systems Inc. is an American laser cleaning system manufacturer and a CWOSB with headquarters in Illinois. Our unique and globally patented laser cleaning technology is proudly designed and made in the USA. This proprietary technology was initially developed to clean cultural heritage buildings and artifacts with unmatched precision, and has evolved into many heavy duty industrial and DoD applications. From making our own scan heads and optics to fabricating our systems with durable stainless steel and powder coated aluminum to endure humid and corrosive environments, we specialize in delivering off the shelf and custom bespoke laser ablation tools that can work during all four seasons worldwide. Notable cultural heritage projects that have utilized our laser ablation technology include the US Supreme Court, the US Senate Building, Notre Dame, Sydney Harbor Bridge, Capitol of Maryland, the Egyptian Obelisk in Central Park, the Smithsonian, and buildings and monuments worldwide. On the industrial side our technology is used for rust removal, paint removal, chloride removal, surface prep, hydrocarbon removal, radiation decontamination, lead abatement, and various other industrial applications that demand precision and efficiency. Branches of the DoD such as the US Army, the US Coast Guard, and the US Air Force use our laser equipment to maintain and service valuable assets.

Focus Area: Coating and Corrosion Prevention

Contact

Magdalena Dajnowski

magdalena@gclasers.com

844-532-1064

Laser Cleaning Equipment

Google Public Sector

Google Public Sector brings the magic of Google to the mission of government and education. With powerful technologies such as artificial intelligence (AI), advanced analytics, and security offerings, decision makers can streamline processes and improve citizen services delivered by public sector organizations across all domains.

Focus Area: Business IT and Analytics

Contact

Shawn Mayo-Pike

518.322.7467

shawnjpike@google.com

Automating Shipyard Workflows with AI

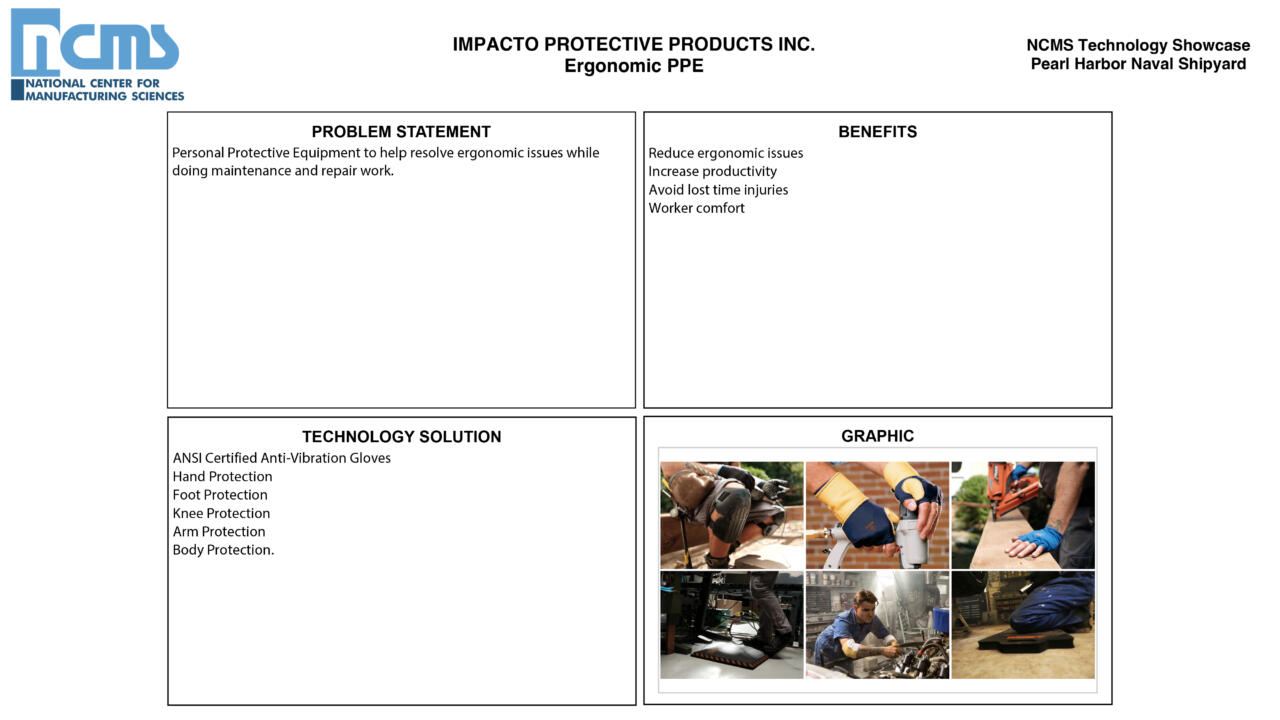

Impacto Protective Products

As a leader in the personal protective product industry Impacto Protective Products provides customers with innovative products that enhance safety and productivity in the workplace. Our network of sales staff works closely with customers across a wide range of industries to produce measurable results.

We have long been recognized for products that protect against workplace injuries by assuring exceptional levels of protection. We specialize in design, manufacturing and distribution of custom ergonomic products to help prevent a wide range of cumulative trauma and repetitive strain injuries.

Impacto® products are distributed around the world and are used in many job applications including manufacturing, warehousing, assembly lines, industrial applications, construction, mining industry, forestry, office settings and many more.

Focus Area: Energy, Environmental, Health, and Safety

Contact

Ergonomic PPE

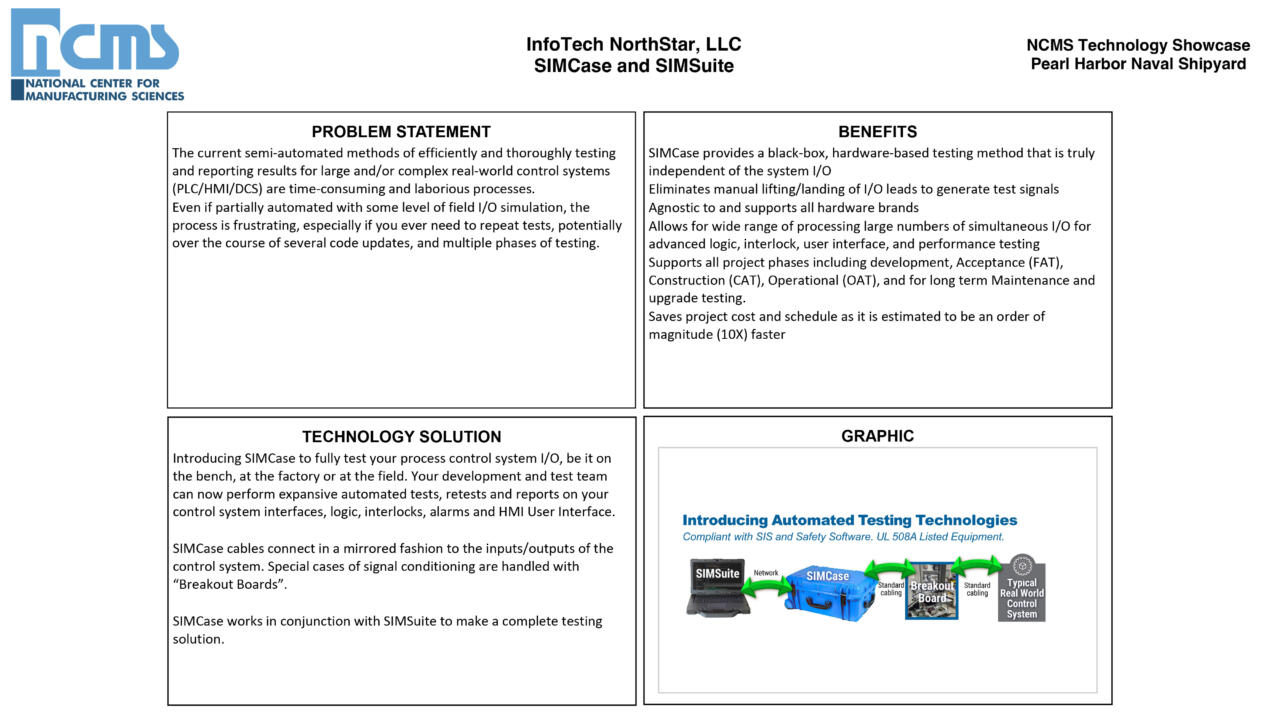

InfoTech NorthStar, LLC

InfoTech NorthStar, LLC (ITNS) provides professional, technical and engineering support services in several related fields for all phases and types of project, task and service-based work. When we started ITNS, we saw a need in the Government Sector to offer these types of wide-ranging services. ITNS is based in Richland, Washington, and supports the community by hiring many of our employees locally. ITNS is a small, disadvantaged, woman-owned business that while local first, is expanding its reach throughout the entire Government Sector with its task and professional, technical and engineering support services focused offerings. ITNS, LLC was formed and is registered in Washington State in October of 2021 as a consortium of local, experienced Government contractors with over 50 years of combined experience at Government sites around the country. ITNS, LLC is registered with the Washington Secretary of State, Corporation Commissioner and maintains licensed Professional Engineers (P.E.) and other credentialed personnel in many fields on its team.

Focus Area: Enhanced Inspection

Contact

Nolan Wright

nolan.wright@infotechnorthstar.com

509-531-8890

SIMCase and SIMSuite

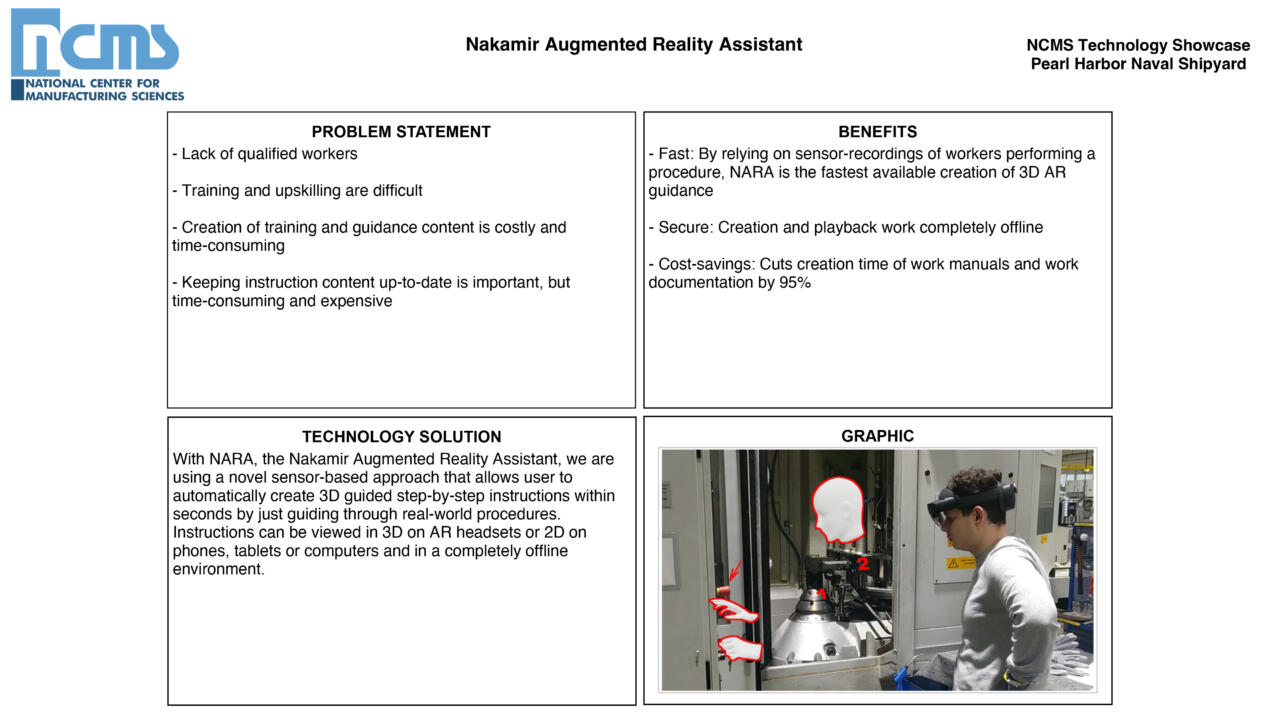

Nakamir Inc

Augmented Reality and AI for training and guidance of work procedures in shipyards.

NARA, the Nakamir Augmented Reality Assistant, combines state-of-the-art Augmented Reality and AI for easy creation of professional user manuals and work documentation. With NARA, workers record and describe tasks in their own words, the AI processes that data to create a structured training and guidance output without any additional time to your work. NARA runs offline on AR headsets, tablets and phones with data processing possible on a secure workstation or cloud environment.

1 minute of instructions takes only 1 minute to create. No editing, coding, or no-code software needed.

Focus Area: Workforce Development/Visualization

Contact

Christoph Leuze

650.250.9332

cleuze@nakamir.com

www.nakamir.com

Nakamir Augmented Reality Assistant

NPO

For over 45 years, NPO has specialized in manufacturing a vast array of radiation shielding products. NPO has an extensive portfolio of shielding materials including T-Flex® (constituted from high Z metals such as tungsten and bismuth in a polymer matrix) and lead wool blankets (flexible lead panels). NPO delivers millions of pounds of shielding each year of which roughly 75% is custom built to meet unique challenges. Our team of engineers specialize in designing solutions for the nuclear industry with a focus on ergonomics and quick installation time. New radiation shielding products are developed regularly. They are analyzed using Monte Carlo N-Particle Analysis (MCNP) simulation and tested in our radioactive materials laboratory. At NPO, we are happy to educate on the science behind dose reduction and demonstrate how various shielding materials compare. NPO is ISO: 9001:2015 compliant, NIOSH certified, and all manufacturing is performed in the United States of America.

Focus Area: Energy, Environmental, Health, and Safety

Contact

NPO Radiation Shielding

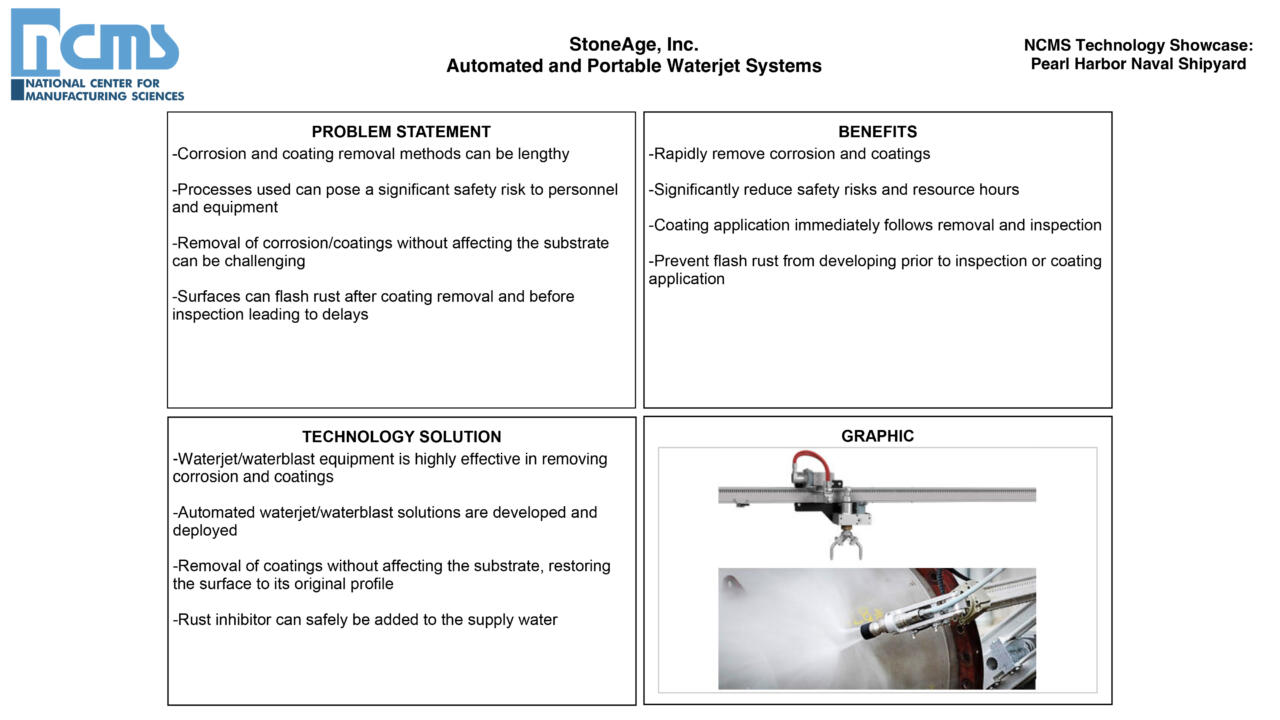

StoneAge, Inc.

StoneAge is an engineering and manufacturing center for high pressure waterblast tools used for industrial cleaning. Our primary focus is to introduce fully automated tooling to remove operators from the dangers of high-pressure water. StoneAge recently acquired Terydon who specializes in heat exchangers and condensers.

Focus Area: Energy, Environmental, Health, and Safety

Contact

Michael Gonzales

303.204.6127

michael.gonzales@stoneagetools.com

www.stoneagetools.com

Automated and Portable Waterjet System

T-C Company

ESCO Tool Company was founded in 1954 and developed the first portable beveling machines for tube and pipe fabrication. After early success on the Trident Nuclear Submarine project, this equipment rapidly became the most popular way to bevel high pressure tube and pipe on‐site. Esco Tool MILLHOG® End Prep Tools are built tough and precision machined in the USA from the finest materials. Boiler tube membrane removal and beveling can be completed in one pass for accurate fit‐ups, which helps ensure high‐quality welds.

Customer feedback has led us to develop our own line of Cohog® clamshell split frames that hold true to our reputation of providing high‐quality manufacturing and reliable products. The Cohog allows users to simultaneously part and bevel heavy‐walled pipe, with a more simplified setup process than competitive split frames. Machined out of aircraft‐grade hard anodized 7075 aluminum and heat treated 4140 steel, we continue to provide a top‐quality product.

ESCO Tool now has a line of over 23 field‐proven products that are used all over the world in power generation plants, pulp and paper plants, refineries, fabrication facilities, public work systems, and other metalworking industries.

Focus Area: Advanced/Additive Manufacturing

Contact

Paul Arnesen

pal@t-ccompany.com

208.871.5445

Precision field machining used to provide the ideal pipe end-prep bevel profile for various types of welding as well as resurfacing of gasket faces on raised face flanges.

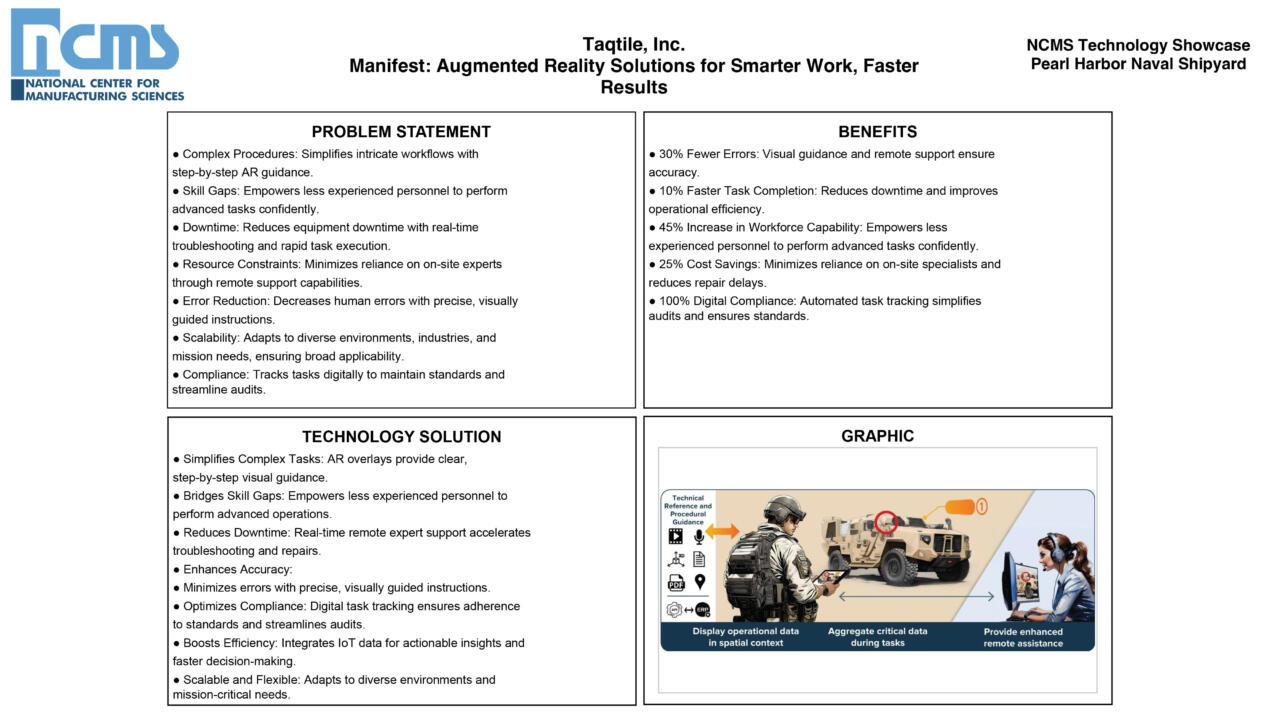

Taqtile, Inc.

Taqtile specializes in augmented reality (AR) solutions that simplify complex tasks, enhance training, and improve operational efficiency. Our flagship platform, Manifest, delivers innovative tools to empower users across defense and commercial industries.

Focus Area: Advanced/Additive Manufacturing

Contact

Kelly Malone

kelly.malone@taqtile.com

206–227–4419

Technology Title

NCMS Technology Showcase – Pearl Harbor Exhibitor Directorynancy.lamarca2025-03-25T12:20:03-04:00