Focus Area: Enhanced Inspection

Contact

Corey Countryman

corey.j.countryman.civ@us.navy.mil

360-315-7708

FTL Labs Corporation is a small engineering research and development firm in Amherst, Massachusetts. FTL was founded based on a team-building culture that enables us to solve complex multi-disciplinary problems in advanced technology areas with contributions of experts across the globe.

The people at FTL Labs are committed to pushing forward the cutting edge of technology. Working with ingenuity, integrity, and professionalism, we solve our customers’ most challenging problems in aerospace, manufacturing, big data, medical, AI, and robotics sectors.

Some of FTL’s capabilities include:

- Rapid Prototype Design and Engineering

- Optics, Imaging, and Sensing

- Fuels and Fluids Analysis

- Human Performance Optimization

- Biotechnology

- Big Data and Artificial Intelligence

- VR/AR and Advanced Interfaces

- Custom Software Solutions

The process of transforming enabling-technologies into profitable technology products requires orchestration of a variety of human resources including scientists, engineers, technicians, and business development professionals. FTL personnel have long experience with managing groups of interdisciplinary professionals and staying on-task, on-schedule, and on-budget.

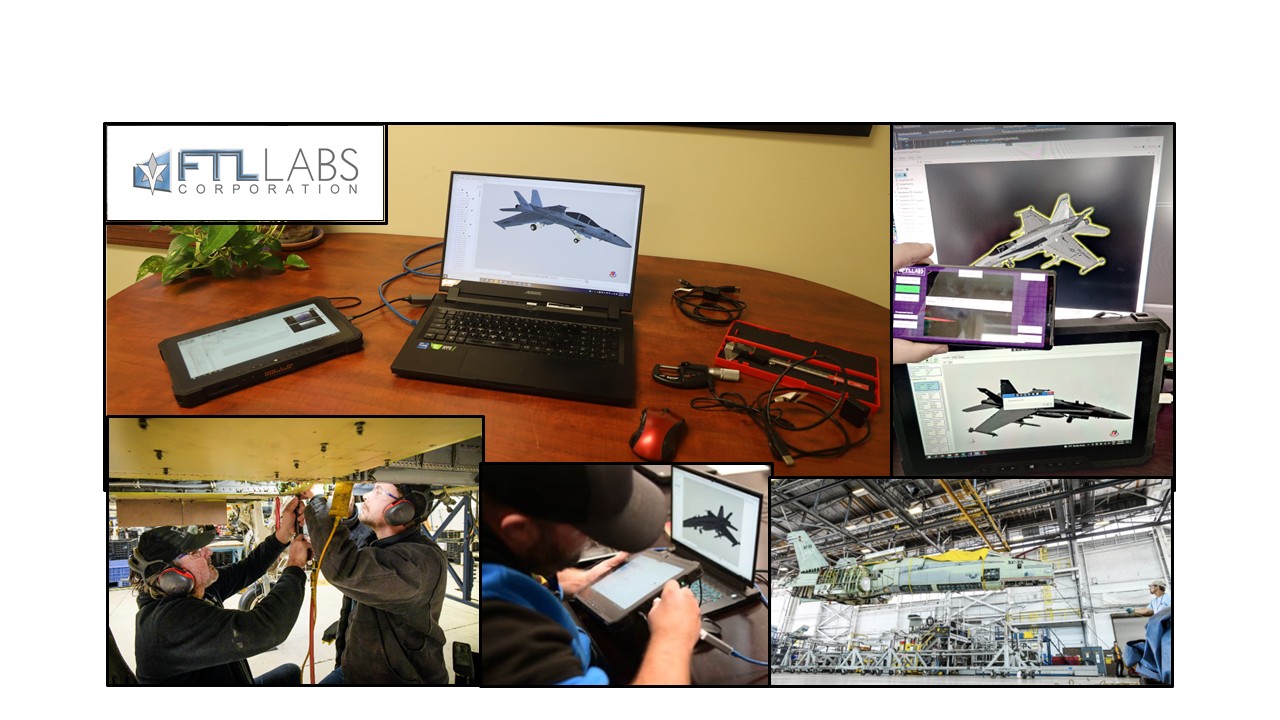

DADTMA (Distributed Acquisition Digital Twin Maintenance Architecture)

Problem Statement:

Traditional Maintenance, Repair, and Overhaul (MRO) practices in the DoD are struggling to adapt to increasing complexities in aircraft maintenance and quality assurance processes, including the use of digital tools and automated technologies to capture maintenance data and streamline workflow management. Current processes are inefficient, requiring time-intensive human-performed inspections and data collection before, during, and after maintenance tasks. The process frequently requires tedious and error-prone record keeping with pen and paper before transcription to a computer for access by teams.

Technology Solution Statement:

DADTMA is a software solution designed to collect, store, and analyze damage and repair data during naval depot maintenance and sustainment activities. DADTMA consists of a tablet app and a web app working in concert to rapidly collect data and store it in a Digital Twin in a secure GovCloud database. It employs automated USB tool data entry, 2D and 3D imaging, graphical database storage, data mining tools, and graphical data analysis to locate and track maintenance issues that are otherwise difficult to discern. It enables communication of that information across the Navy’s current software ecosystem. Ultimately DADTMA will provide a Naval Depot Maintenance and Sustainment tool that will increase the efficiency, repeatability, and accuracy of inspection results, for any asset type.

DADTMA integrates with USB tools used on depot shop floors and helps artisans organize that data by creating customized grids on 2D images of the work area. It then streamlines data sharing across sustainment roles by creating reports and integrating data to DADTMA’s web app. DADTMA’s website is accessible to anyone with the correct credentials, per our DoD customer’s defined roles. Finally, DADTMA’s Digital Twin provides predictive maintenance insights by comparing past maintenance events across a single or similar asset(s).

Benefits Statement:

Reducing costs and shortening maintenance turn-around times at aircraft depots is a high priority for the Navy. Responding to this need, DADTMA reduces manpower-intensive engineering costs associated with repair and maintenance inspections by accelerating data collection on depot floors and enabling the transfer of that data, along with asset and maintenance process information to the DADTMAnet Digital Twin. Primes such as Northrop Grumman anticipate a 10% time-reduction in inspections, yielding $10M in savings in lifecycle cost for a single product.