Focus Area: Coating and Corrosion Prevention

Contact

Magdalena Dajnowski

magdalena@gclasers.com

844-532-1064

G.C. Laser Systems Inc. is an American laser cleaning system manufacturer and a CWOSB with headquarters in Illinois. Our unique and globally patented laser cleaning technology is proudly designed and made in the USA. This proprietary technology was initially developed to clean cultural heritage buildings and artifacts with unmatched precision, and has evolved into many heavy duty industrial and DoD applications. From making our own scan heads and optics to fabricating our systems with durable stainless steel and powder coated aluminum to endure humid and corrosive environments, we specialize in delivering off the shelf and custom bespoke laser ablation tools that can work during all four seasons worldwide.

Laser Cleaning Technology

Problem Statement:

Removing corrosion and coatings from a variety of surfaces can be challenging and the process of abrasive corrosion removal can wear down the thickness of the assets being cleaned, reducing its useful service life, as well as pose environmental concerns with traditional blasting media and chemical stripping containment. Traditional cleaning techniques rely on consumables and have a lot of clean up and disposal costs.

Technology Solution Statement:

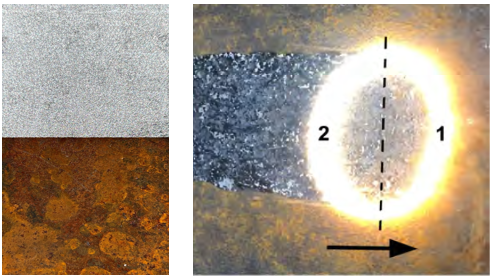

G.C. Laser Systems offers environmentally friendly, durable, and compact portable laser systems for removing rust, paint, coatings, and contamination from surfaces. Built with an in depth understanding of the photomechanical, photothermal, and photochemical effects that laser pulses can have on a surface, our highly tunable systems offer unmatched precision, control, and repeatability with laser ablation cleaning and surface prep. Corrosion, salts, and coatings are removed from metal surfaces without causing any damage or thickness loss to the substrate.

Benefits Statement:

- Environmentally friendly.

- No consumables.

- No damage to substrate being cleaned.

- Less heat on surface than other laser ablation systems.

- Patented high speed and hot-spot-free laser cleaning.

- The beam never stops in one place and rotates at high RPM.

- 2-3 times faster cleaning than competitors.

- Designed and made in the USA.

- Made for use in humid and corrosive environments.